NeoDen SMD Reflow Station

NeoDen SMD Reflow Station

Specification

1. The unique design of heating module has the characteristics of high temperature control accuracy, uniform temperature distribution in the thermal compensation area, high thermal compensation efficiency and low power consumption.

2. High-performance aluminum alloy heating plate instead of heating pipe, both energy-saving and high-efficient, and transverse temperature deviation is significantly reduced compare to the similar reflow oven products in the market.

3. Lightweight, miniaturization, professional industrial design, flexible application site, more user-friendly.

4. Beautiful and elegant indicator design with red, yellow and green alarm function.

Feature

Product name: NeoDen SMD Reflow Station

Cooling fan: Upper4

Conveyor speed: 50~600 mm/min

Temperature range: Room temperature~300℃

PCB temperature deviation: ±2℃

Max soldering height(mm): 35mm (includes PCB thickness)

Max soldering width (PCB Width): 350mm

Length process chamber: 1354mm

Electricity supply: AC 220v/single phase

Machine size: L2300mm×W650mm×H1280mm

Heat-up time: 30 min

Net weight: 300Kgs

Details

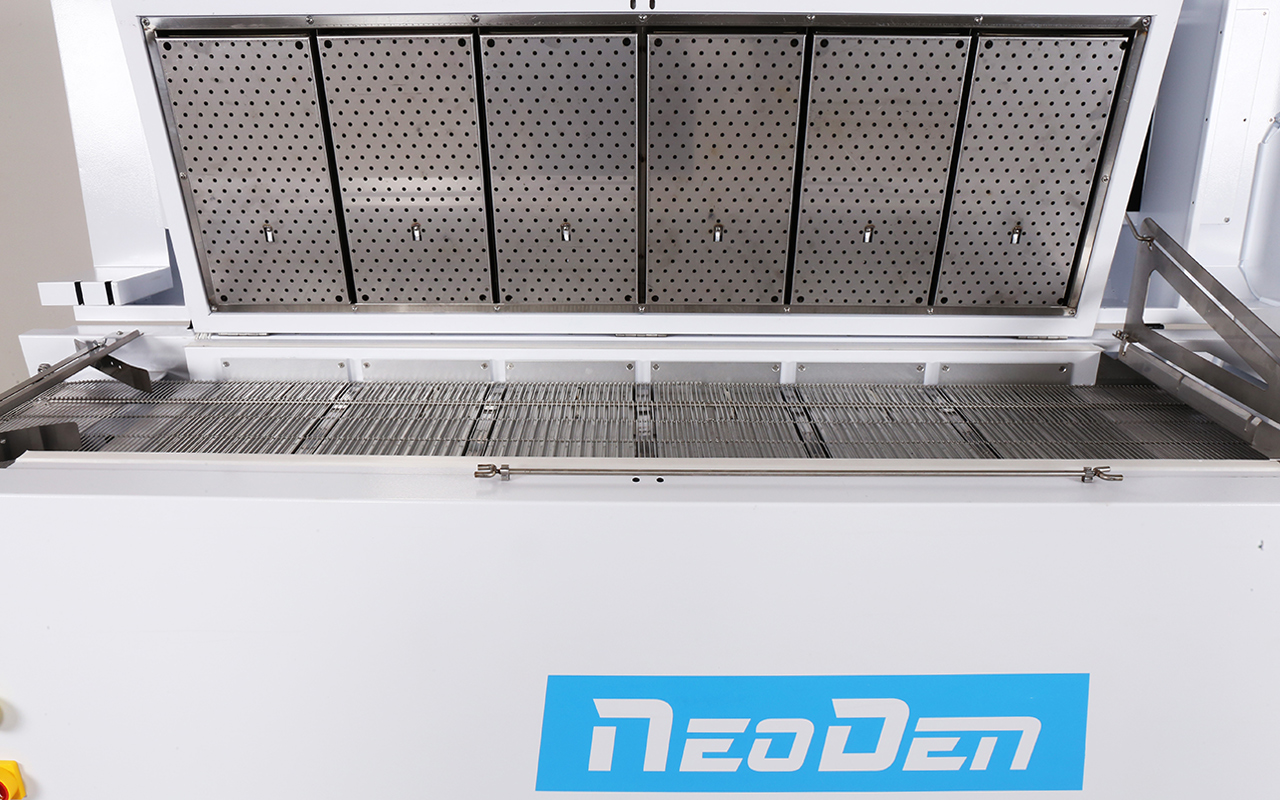

12 temperature zones

High temperature control accuracy

Uniform temperature distribution in the thermal compensation area

Cooling zone

Independent circulating air design

Isolates the influence of the external environment

Energy saving & Eco-friendly

Welding smoke filtering system

low power consumption, low power supply requirements

Operation panel

Hidden screen design

convenient for transportation

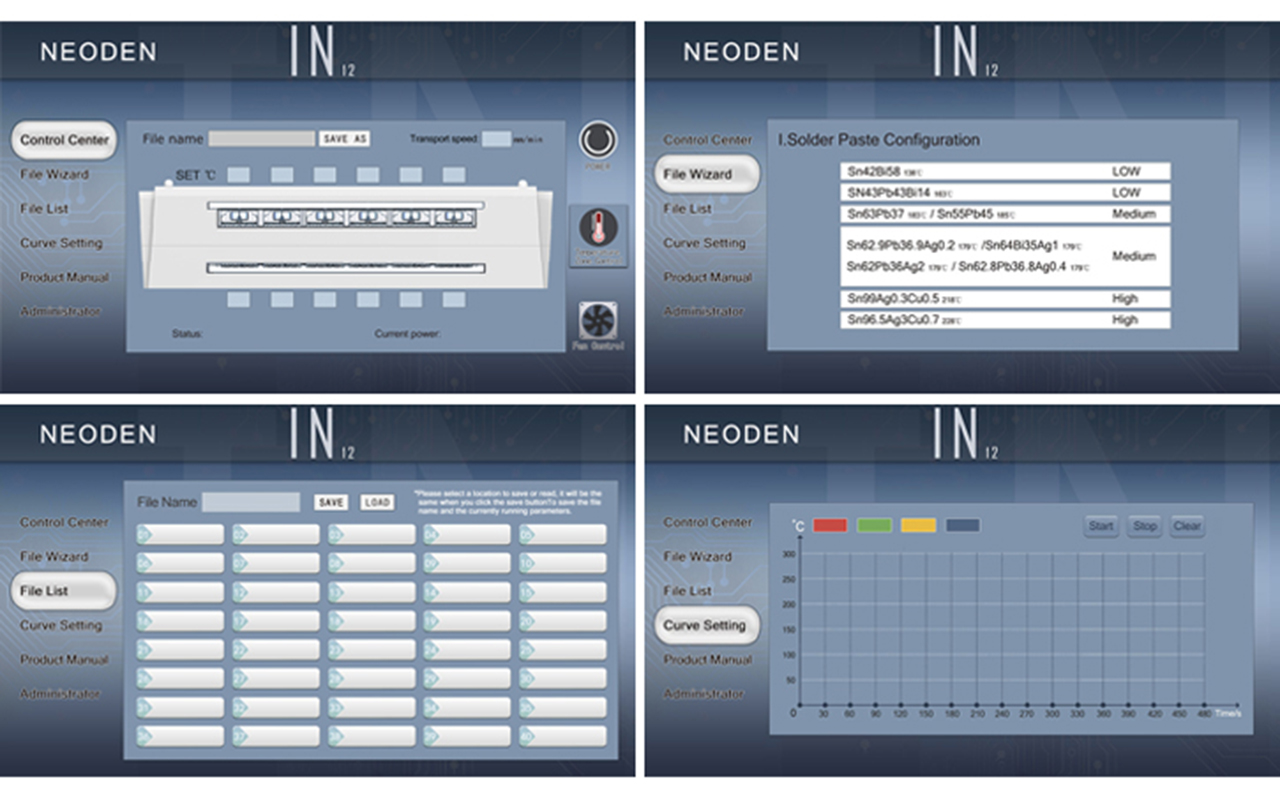

Intelligent control system

Custom developed intelligent control system

Temperature curve can be displayed

Elegant appearance

In line with high-end use environment

Lightweight, miniaturization, professional

About NeoDen IN12

SMT reflow soldering equipment technology has experienced different forms of development process, such as plate radiation heating, quartz infrared tube heating, infrared hot air heating, forced hot air heating, forced hot air heating and nitrogen protection.

The increased requirements of the reflow oven cooling process have also contributed to the development of the SMT reflow soldering equipment cooling zone, from room temperature natural cooling, air cooling to water cooling system designed for lead-free welding.

FAQ

Q1: Can you do OEM and ODM?

A: Yes, OEM and ODM are both acceptable.

Q2: What’s the MOQ for your products?

A:Usually 1 set.

Q3: How far is your factory from the airport and train station?

A: From airport about 2 hours by car, and from train station about 30 minutes.

We can pick up you.

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. In our global Ecosystem, we collaborate with our best partners to deliver a more closing sales service, high professional and efficient technical support.

① NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040

② Listed with CE and got 50+ patents

Exhibition

Certification

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.