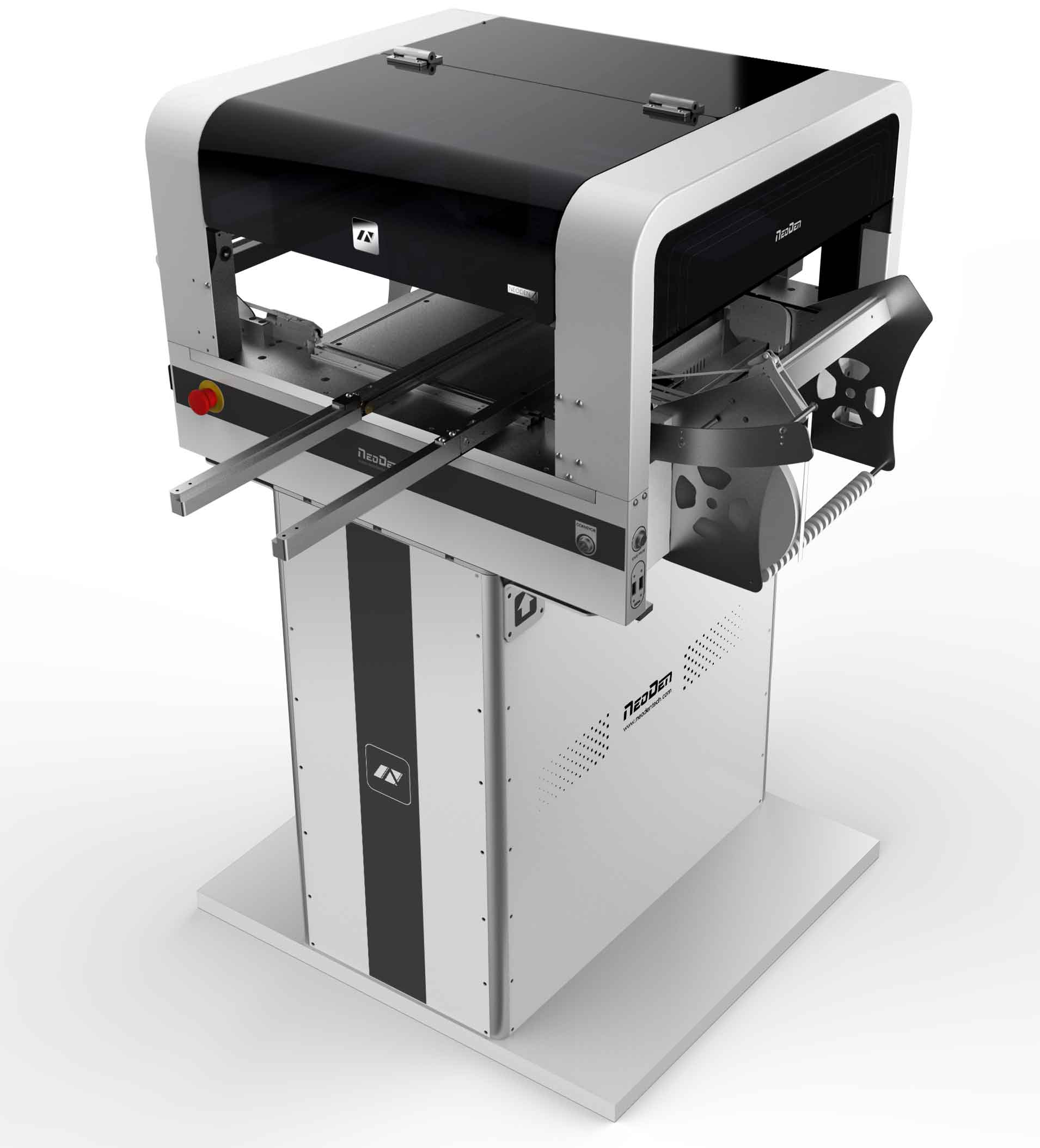

NeoDen SMD Assembly Machine

NeoDen SMD Assembly Machine

The fourth-generation model

Specification

Product name: NeoDen SMD Assembly Machine

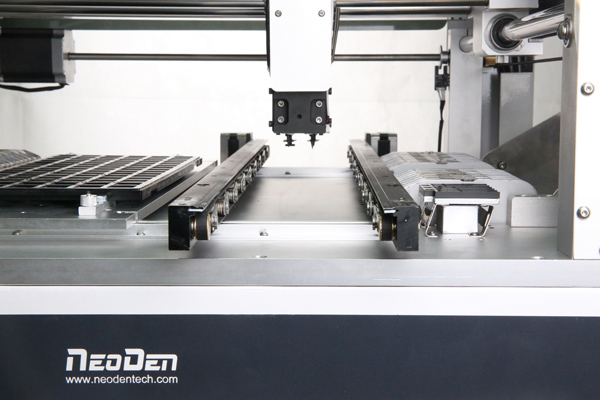

Machine Style: Single gantry with 4 heads

Placement Rate: 4000 CPH

External Dimension: L 870×W 680×H 480mm

Max applicable PCB: 290mm*1200mm

Feeders: 48pcs

Average working power: 220V/160W

Component Range: Smallest Size: 0201, Biggest Size: TQFP240, Max Height: 5mm

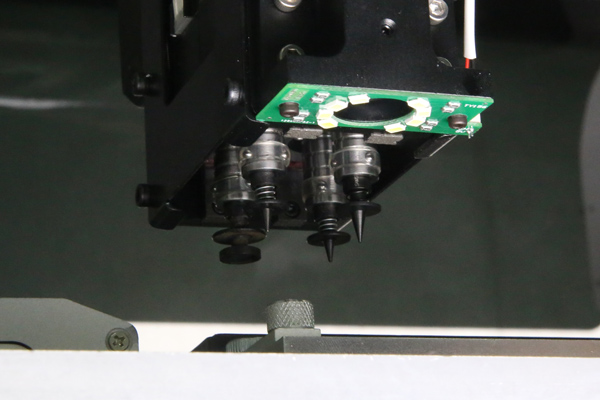

Four placement heads

The mounting head is designed in a suspended, fully symmetric and high degree of coupling way, ensure it can mount components with higher space, more gentle and more efficient.Surprisedly, we design and equip with four high precision nozzles. They can mount at the same time with 360 degrees rotation at -180 to 180.

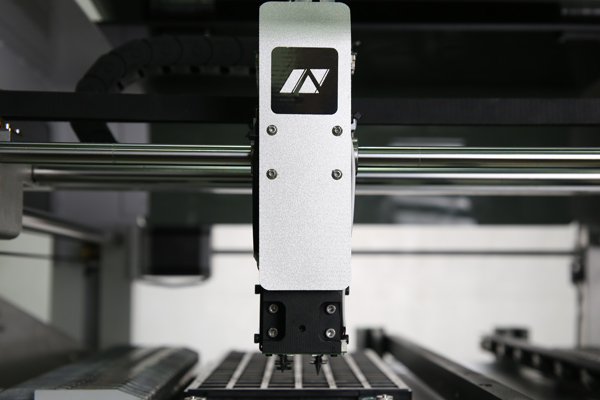

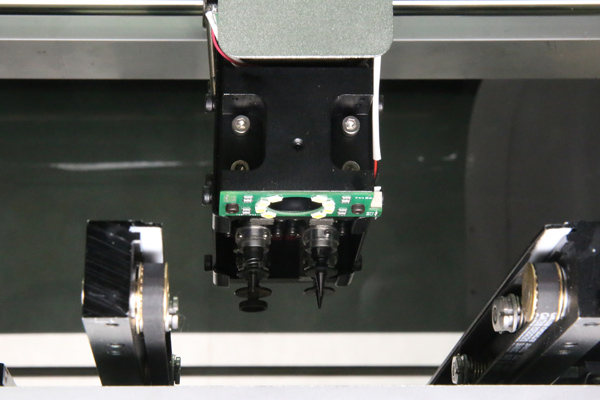

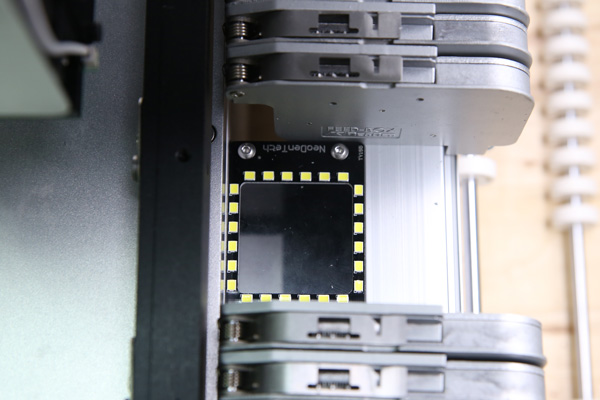

Dual Vision System

Installed with high speed industry CCD cameras, and work with our patented image distortion processing algorithms, enable cameras can recognize and align different components of four nozzles. With the help of upper-camera and down looking camera, they will display the picking process with high definition image. Multiply efficiency while ensure accuracy.

Auto Rail

Support two different ways for PCB positioning, both seamless mounting via automatic rails and PCB self-positioning mounting. Both tube and tray package ICs can be supported at the same time, it also can be extended a vibrating plate to support bulk components, moreover, the universal conveyor port can help users achieve automatic production without labors at all, to keep the best mounting without bother.

Automatic Electric Feeders

New patented electronic feeders adopts new technique—feeding error corrections, which smooths the feeding and picking. Meanwhile, Neoden 4 has increased the maximum feeders from 27 to 47.

Package

If you need, please feel free to contact us for more information.

Our Service

1. More Professional service in PNP machine field

2. Better manufacture ability

3. Various payment term to choose: T/T, Western Union, L/C, Paypal

4. High quality/Safe material/Competitive price

5. Small order available

6. Quickly response

7. More safe and fast transport

About us

Factory

Certification

Exhibition

FAQ

Q1: Do you have a export licence?

A: Yes.

Q2: Can l visit your factory?

A: By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.

Q3: What is your advantage compared with your competitors?

A: (1). Qualified Manufacturer

(2). Reliable Quality Control

(3). Competitive Price

(4). High Efficiency working (24*7hours)

(5). One-Stop Service

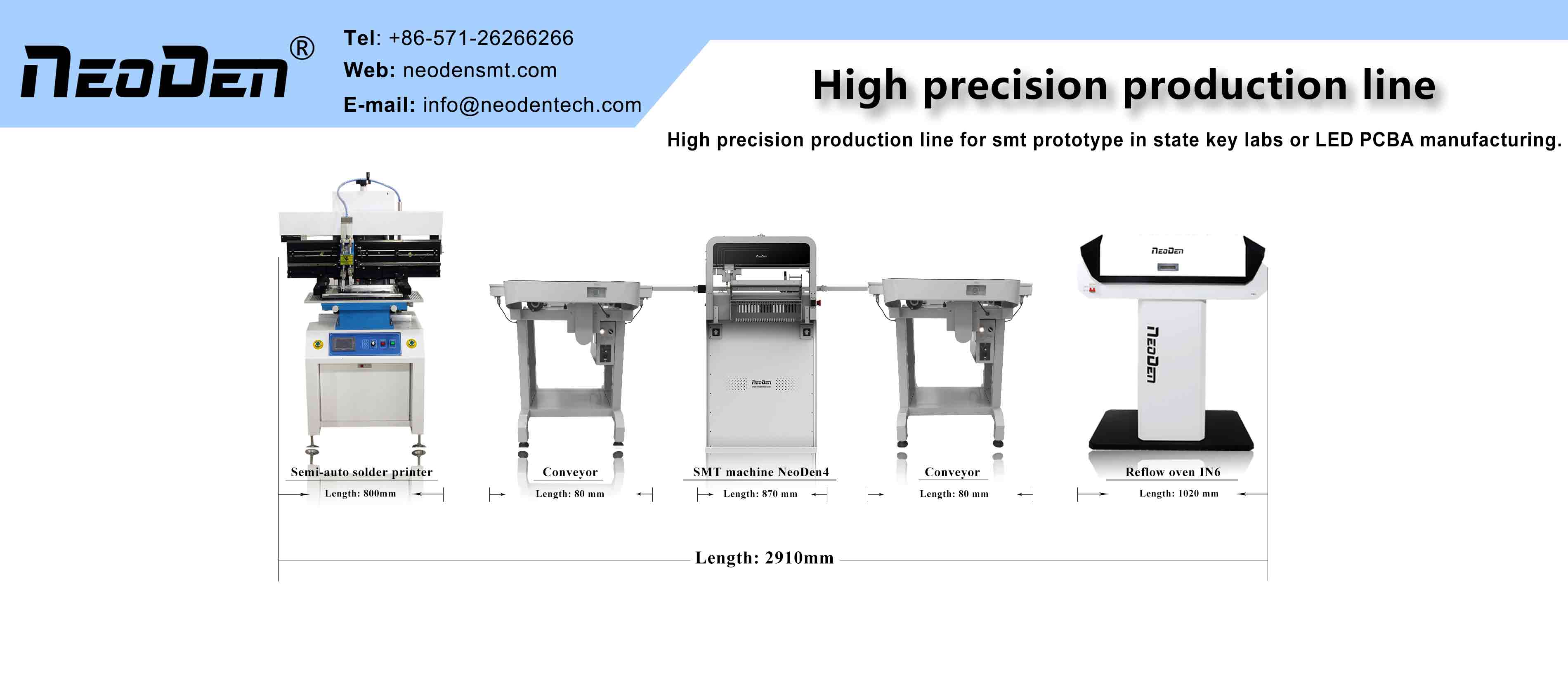

One Stop SMT Equipments Manufacturer

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.