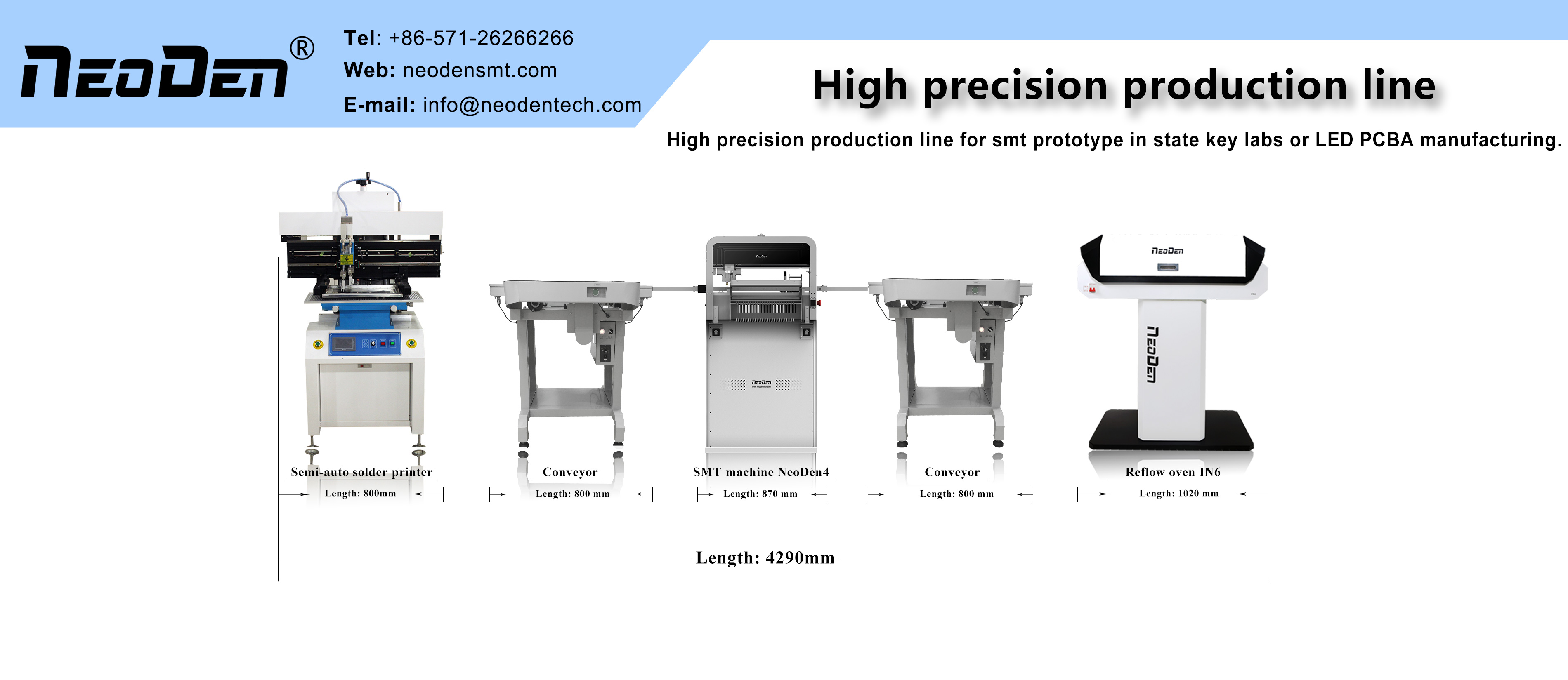

NeoDen Small Reflow Soldering Machine

NeoDen Small Reflow Soldering Machine

6 zones design, light and compact.

Japan NSK hot-air motor bearings and Swiss heating wire, durable and stable.

Reinforced heavy-duty carton package, light-weight and environment-friendly.

The table-top design of the product makes it a perfect solution for production lines with versatile requirements. It is designed with internal automation that helps operators provide streamlined soldering.

The design implements an aluminum alloy heating plate that increases the energy-efficiency of the system. The internal smoke filtering system improves the product’s performance and reduces harmful output, too.

Specification

| Product Name | NeoDen Small Reflow Soldering Machine |

| Power requirement | 110/220VAC 1-phase |

| Power max. | 2KW |

| Heating zone quantity | Upper3/ down3 |

| Conveyor speed | 5 - 30 cm/min (2 - 12 inch/min) |

| Standard Max Height | 26mm |

| Temperature control range | Room temperature~300 degree celsius |

| Temperature control accuracy | ±0.2 degree celsius |

| Temperature distribution deviation | ±1 degree celsius |

| Soldering width | 260 mm (10 inch) |

| Length process chamber | 680 mm (26.8 inch) |

| Heat-up time | approx. 25 min |

| Dimensions | 1020*507*350mm(L*W*H) |

| Packing Size | 112*62*56cm |

| N.W./ G.W. | 49KG/64kg (without working table) |

Detail

Heating zones

6 zones design, (3 top|3 bottom)

Full hot-air convection

Intelligent control system

Several working files can be stored

Color touch screen

Saving energy and Eco-friendly

Built-in solder smoke filtering system

Reinforced heavy-duty carton package

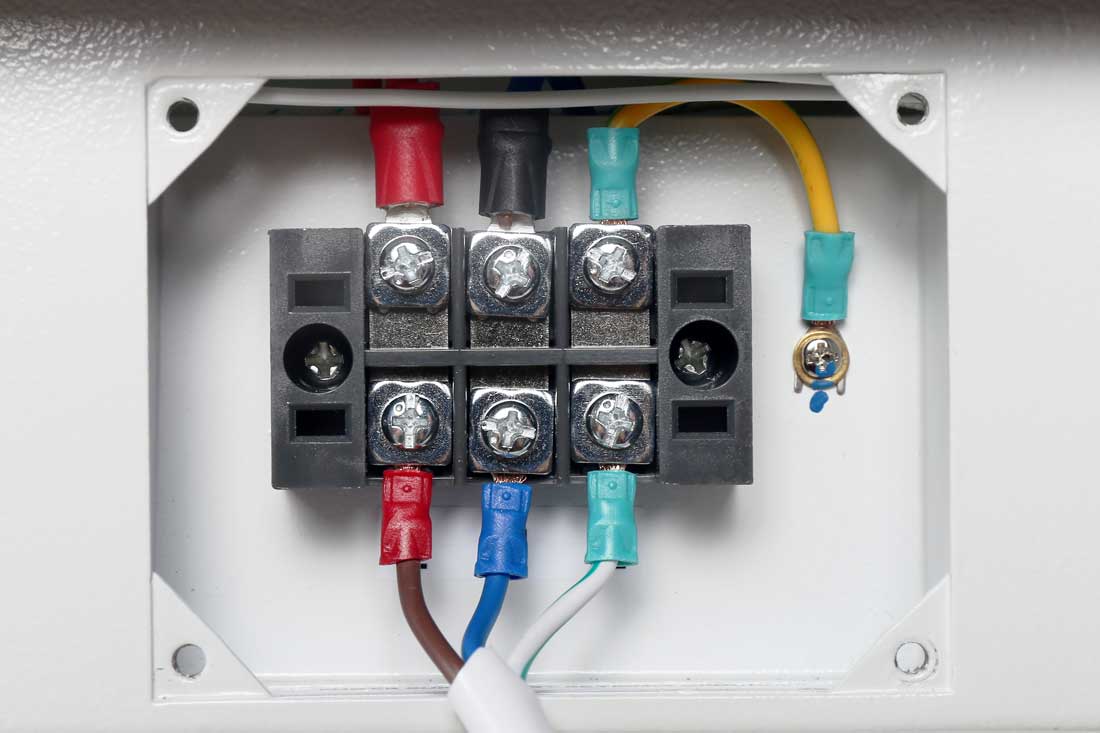

Power Supply Connection

Power supply requirement:110V/220V

Stay away from flammable and explosive

Packaging & Shipping

Packaging:

One piece in one wooden case

Suitable quantity to an export wooden case

other packing accessories in regular

Customer required packing is available

Shipping: by air, sea, or express

Delivery time: about 15~30 days after order details and production confirmed.

FAQ

Q1: Which payment form you can accept?

A: T/T, Western Union, PayPal etc.

We accept any convenient and swift payment term.

Q2: What’s is your shipping service?

A: We can provide services for vessel booking, goods consolidation, customs declaration, shipping documents preparation and delivery bulk at the shipping port.

Q3: Have your products been exported?

A: Yes, they have been exported to USA, Canada, Australia, Russia, Chile, Panama, Nicaragua, UAE, Saudi Arabia, Egypt, Sri Lanka, Nigeria, Iran, Vietnam, Indonisia, Singapore, Greece, Netherland, Georgia, Romania, Ireland, India, Thailand, Pakistan, Philippines, Singapore, HK, Taiwan...

About us

Factory

Established in 2010 with 100+ employees & 8000+ Sq.m. factory of independent property rights, to ensure the standard management and achieve the most economic effects as well as saving the cost.

3 different R&D teams with total 25+ professional R&D engineers, to ensure the better and more advanced developments and new innovation.

Skilled and professional english support&service engineers, to ensure the prompt response within 8 hours, solution provides within 24 hours.

The unique one among all of the Chinese manufacturers who registered and approved CE by TUV NORD.

Certification

Exhibition

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.