NeoDen Pick and Place Machine for PCB Assembly

NeoDen4

Pick and Place Machine for PCB Assembly

The fourth-generation model

Description

Specification

| Product name | NeoDen Pick and Place Machine for PCB Assembly |

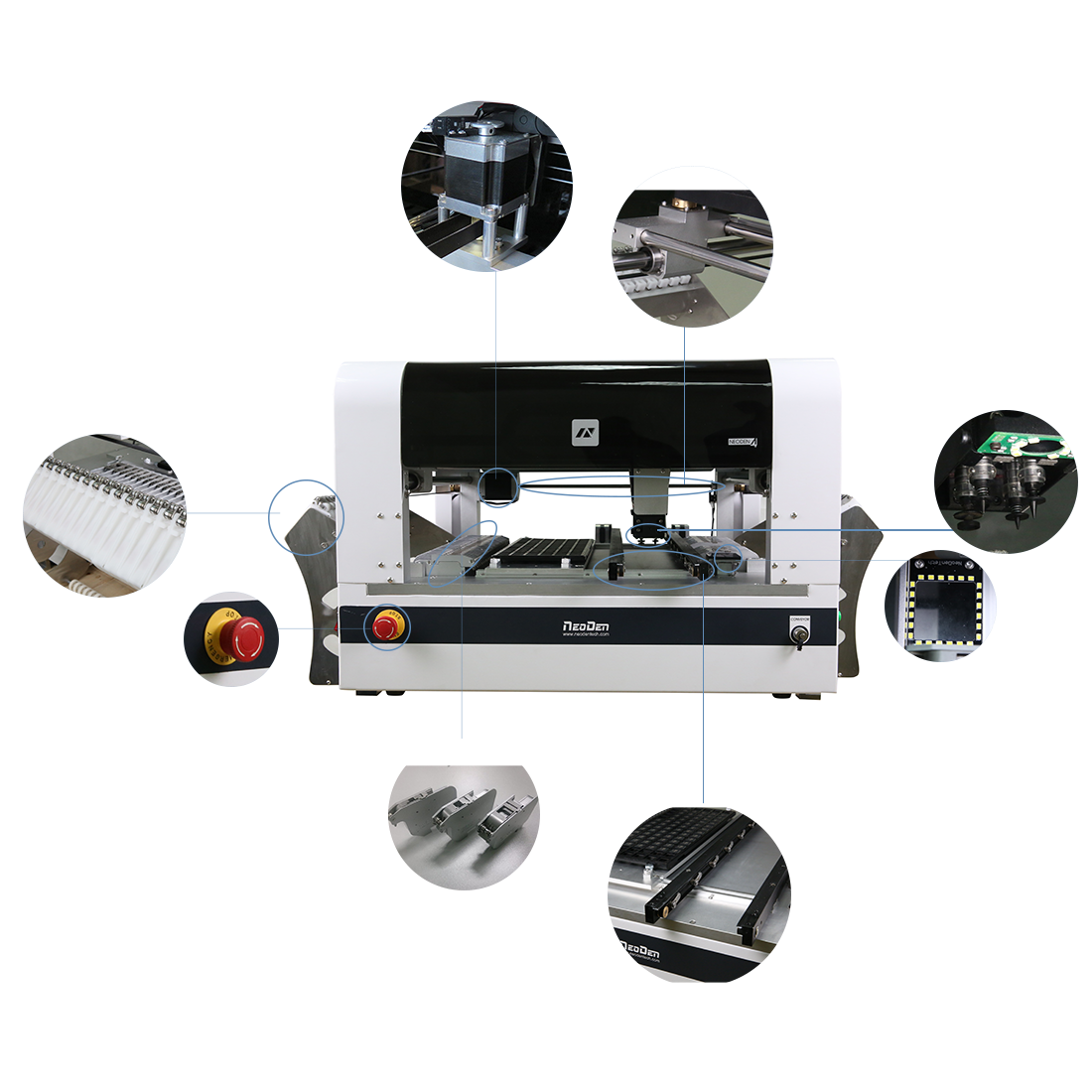

| Machine Style | Single gantry with 4 heads |

| Placement Rate | 4000 CPH |

| External Dimension | L 870×W 680×H 480 mm |

| Max applicable PCB | 290mm*1200mm |

| Feeders | 48pcs |

| Average working power | 220V/160W |

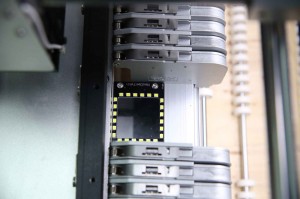

| Component Range | Smallest Size: 0201 |

| Biggest Size: TQFP240 | |

| Max Height: 5mm |

Details

High precision mounting heads,mount at the same time with 360 degrees rotation at -180 to 180.

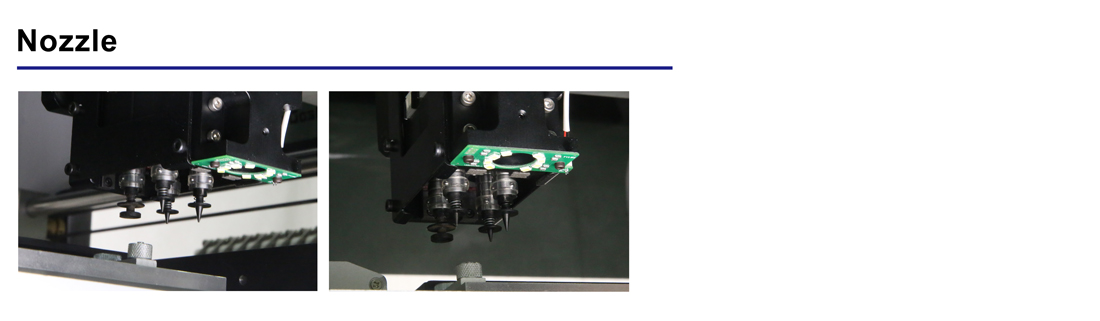

Use standard&generalized nozzles which can help purchase&replace convenient and life assured.

Installed with high speed industry cameras,enables cameras can recognize and align different component for four mounting heads.

With the help of upper-camera and down looking camera, they will display the picking process with high definition image, meet almost all of PCB's producing requirements.

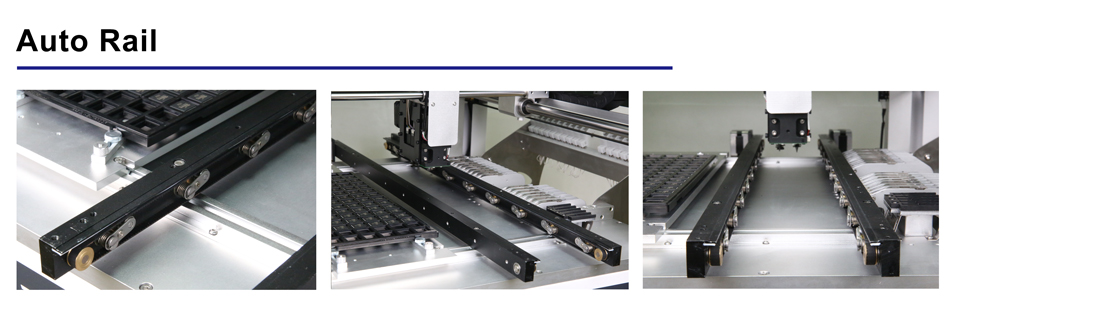

Automatic rails, universal aerial interface, support connect to conventional converor directly, help reach the goal of continuous automatic feeding the boards.

Our brand new patented electronic feeders adopts new technique—feeding error corrections, which smooths the feeding and picking.

Package

If you need, please feel free to contact us for more information.

Edit on the Interface

The entire operation of the NeoDen4 is controlled by a single application that runs automatically after the operating system boots.

Despite the enormous flexibility of the machine, only 7 basic screens are needed to set up feeders, calibrate the vision system and program pick-and-place operations.

This section contains a brief description of the various commands and parameters in the screens.

Section contains a recommended workflow to set up, program and operate the machine.

This screen is the heart of the programming interface. It has two tabs: “PCB Information” and “Feeder Settings.”

In the following sections, this manual will describe each of the functions on the two pages.

About us

Factory

Certification

Exhibition

FAQ

Q1: What is your main market?

A: All over the world.

Q2: How your quality guarantee?

A: We have 100% quality guarantee to customers. We will be responsible for any quality problem.

Q3: Can we visit your factory before place the order?

A: Yes, Very welcome that must be nice to set up good relationship for business.

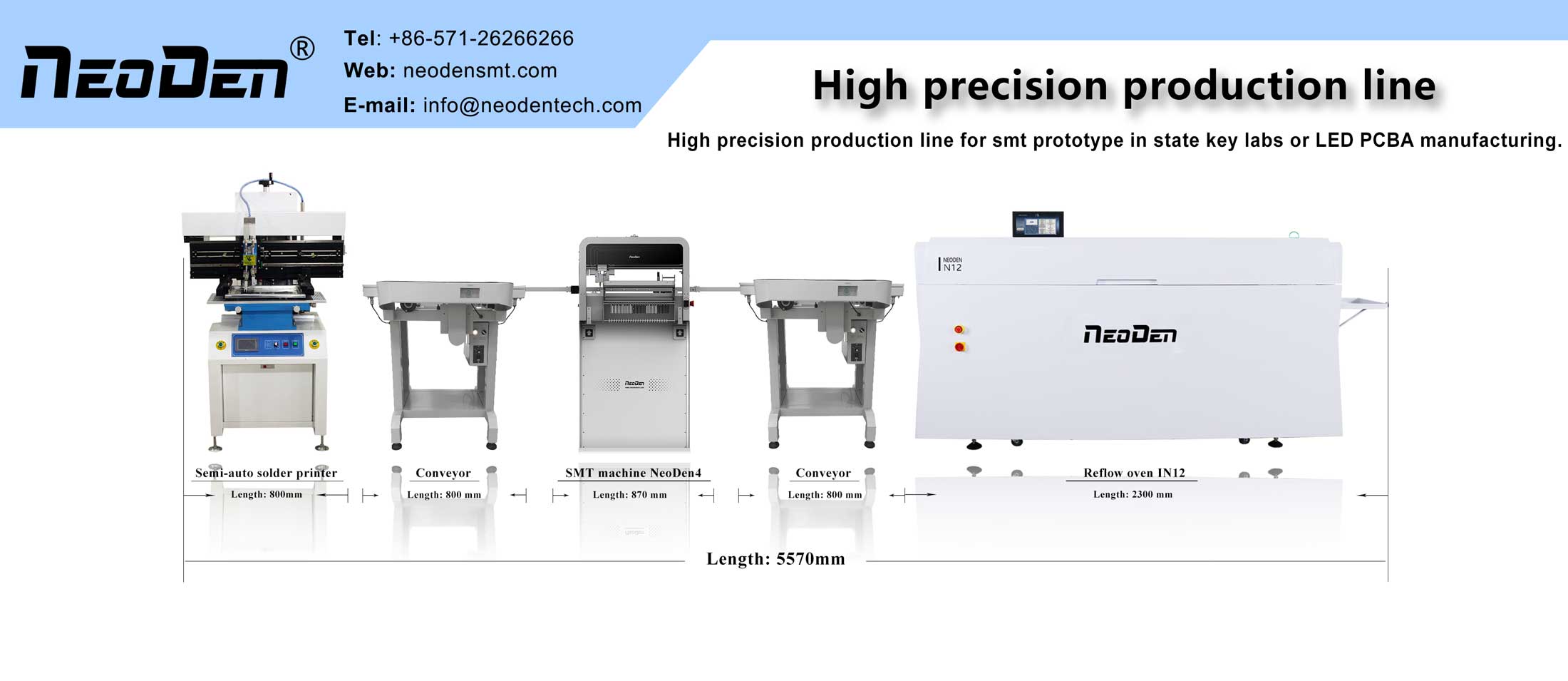

One Stop SMT Equipments Manufacturer

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.