NeoDen PCB SMT Reflow Oven

NeoDen PCB SMT Reflow Oven

Specification

| Product name | NeoDen PCB SMT Reflow Oven |

| Model | NeoDen IN12C |

| Heating Zone Quantity | Upper6 / Down6 |

| Cooling Fan | Upper4 |

| Conveyor Speed | 50~600 mm/min |

| Temperature Range | Room temperature~300℃ |

| Temperature Accuracy | 1℃ |

| PCB Temperature Deviation | ±2℃ |

| Max soldering height (mm) | 35mm (includes PCB thickness) |

| Max Soldering Width (PCB Width) | 350mm |

| Length Process Chamber | 1354mm |

| Electricity Supply | AC 220v/single phase |

| Machine Size | L2305mm×W612mm×H1230mm |

| Heat-up Time | 30 min |

| Net Weight | 300Kgs |

Details

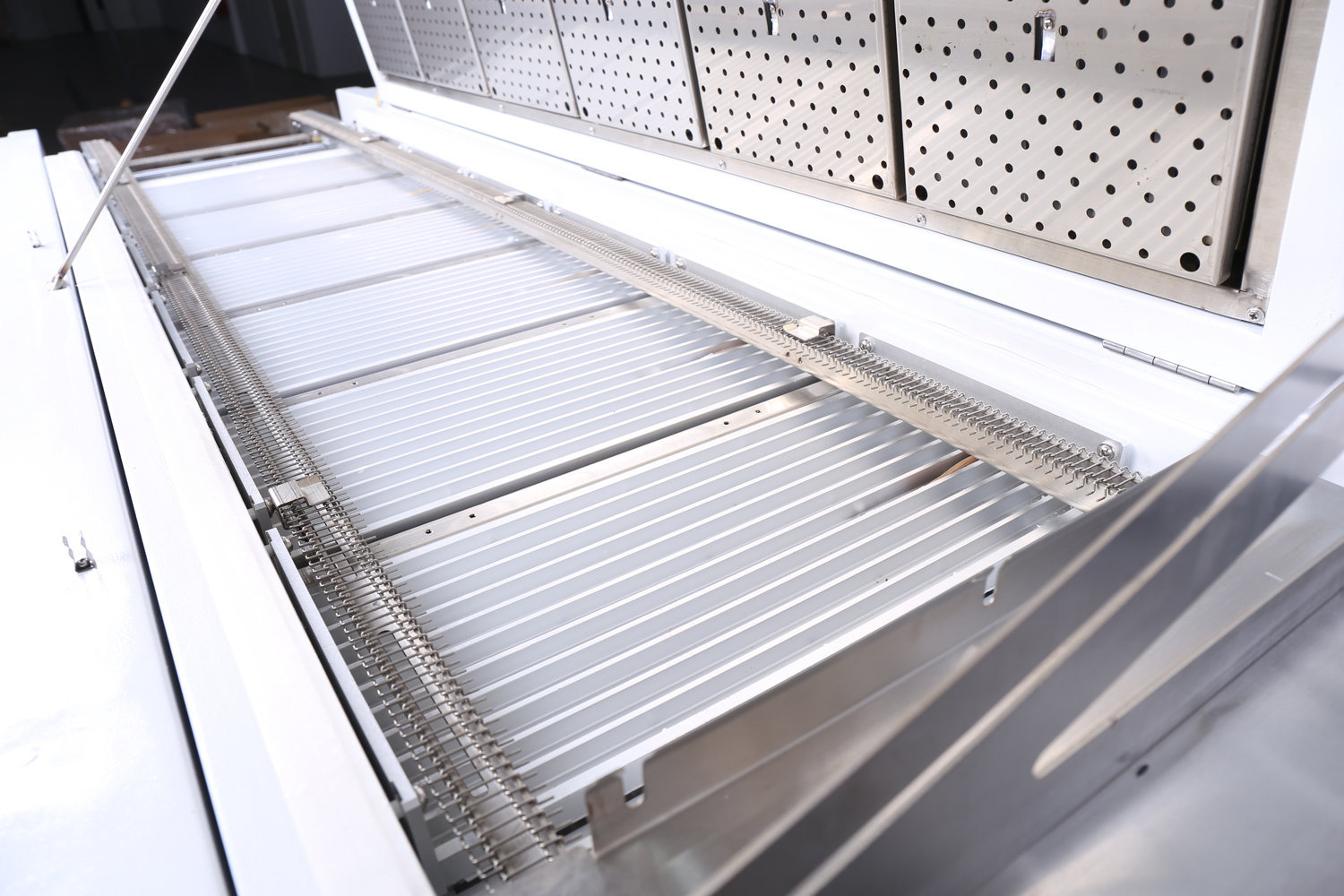

12 Heating Zones

Uniform temperature

High temperature control accuracy

Cooling zone

Independent circulating air design

Isolates the influence of the external environment

Energy saving & Eco-friendly

Welding smoke filtering system

low power and supply requirements

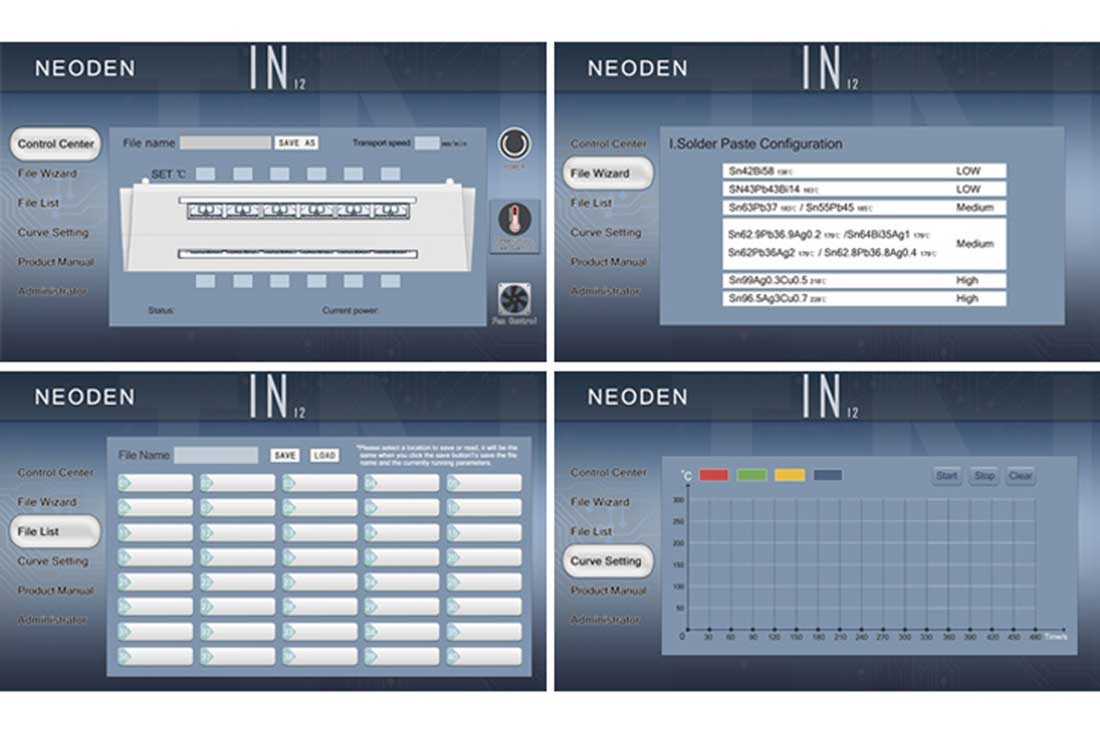

Operation panel

Hidden screen design

Convenient for transportation

Intelligent control system

Custom developed intelligent control system

Temperature curve can be displayed

Elegant appearance

In line with high-end use environment

Lightweight, miniaturization, professional

Brief Introduction

N12C is a new environmentally friendly, stable performance intelligent automatic orbital reflow soldering.

This reflow solder adopts the exclusive patented design of "even temperature heating plate" design, with excellent soldering performance.

with 12 temperature zones compact design, lightweight and compact.

to achieve intelligent temperature control, with high-sensitivity temperature sensor, with stable temperature in the furnace, the characteristics of small horizontal temperature difference.

while using Japan NSK hot air motor bearings and Switzerland imported Heating wire, durable and stable performance.

And through the CE certification, to provide authoritative quality assurance.

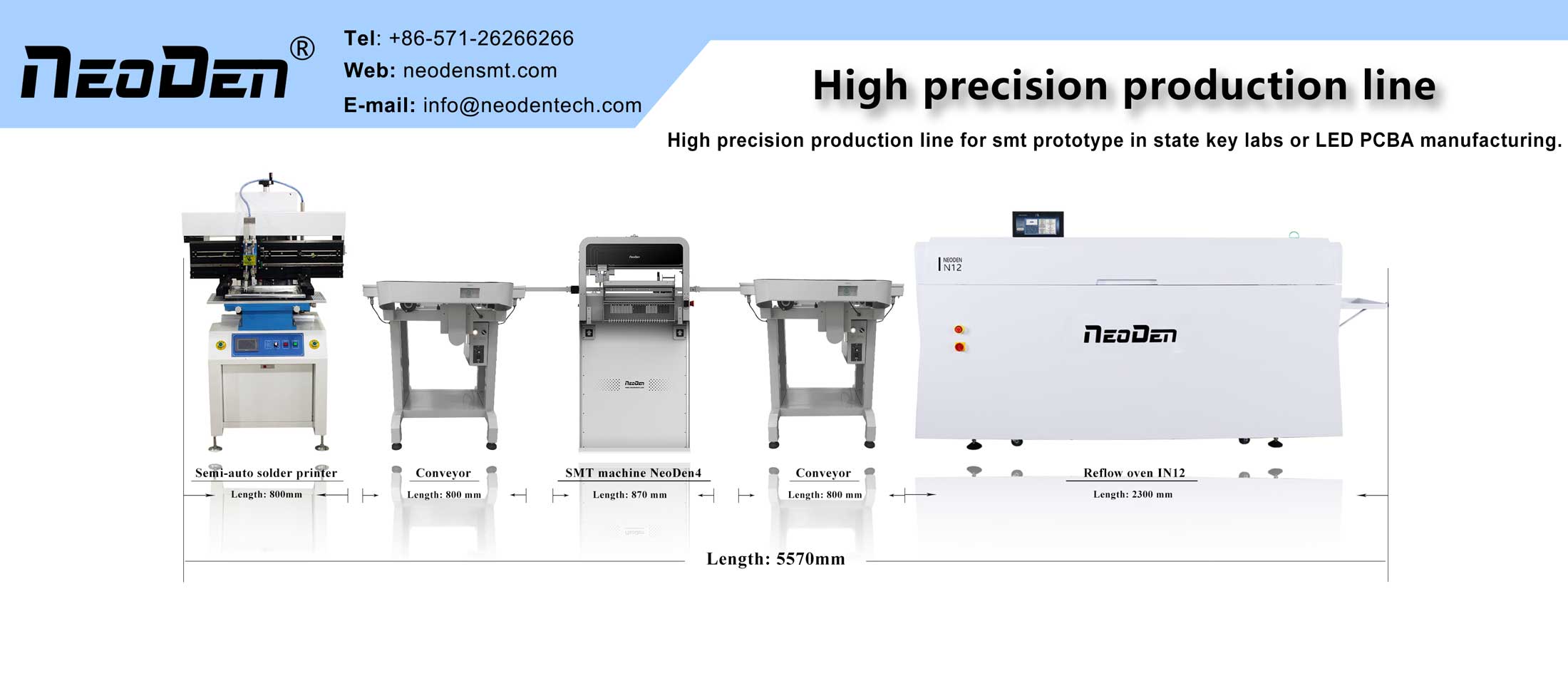

Provide one-stop SMT assembly production line

Related products

FAQ

Q1. When can I get the price?

A: Usually we quote within 8 hours after we get your inquiry.

Q2. What about the lead time for mass production?

A: Honestly, it depends on the order quantity and the season you place the order.

Alway 15-30 days based on general order .

Q3. What is your terms of delivery?

A: We accept EXW, FOB, CFR, CIF, etc.

You can choose the one which is the most convenient or cost effective for you.

About us

Factory

Company Profile

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

with global presence in over 130 countries, the excellent performance, high accuracy and reliability of NeoDen PNP machines make them perfect for R&D, professional prototyping and small to medium batch production.

We provide professional solution of one stop SMT equipment.

In our global Ecosystem, we collaborate with our best partners to deliver a more closing sales service, high professional and efficient technical support.

Exhibition

Certification

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.