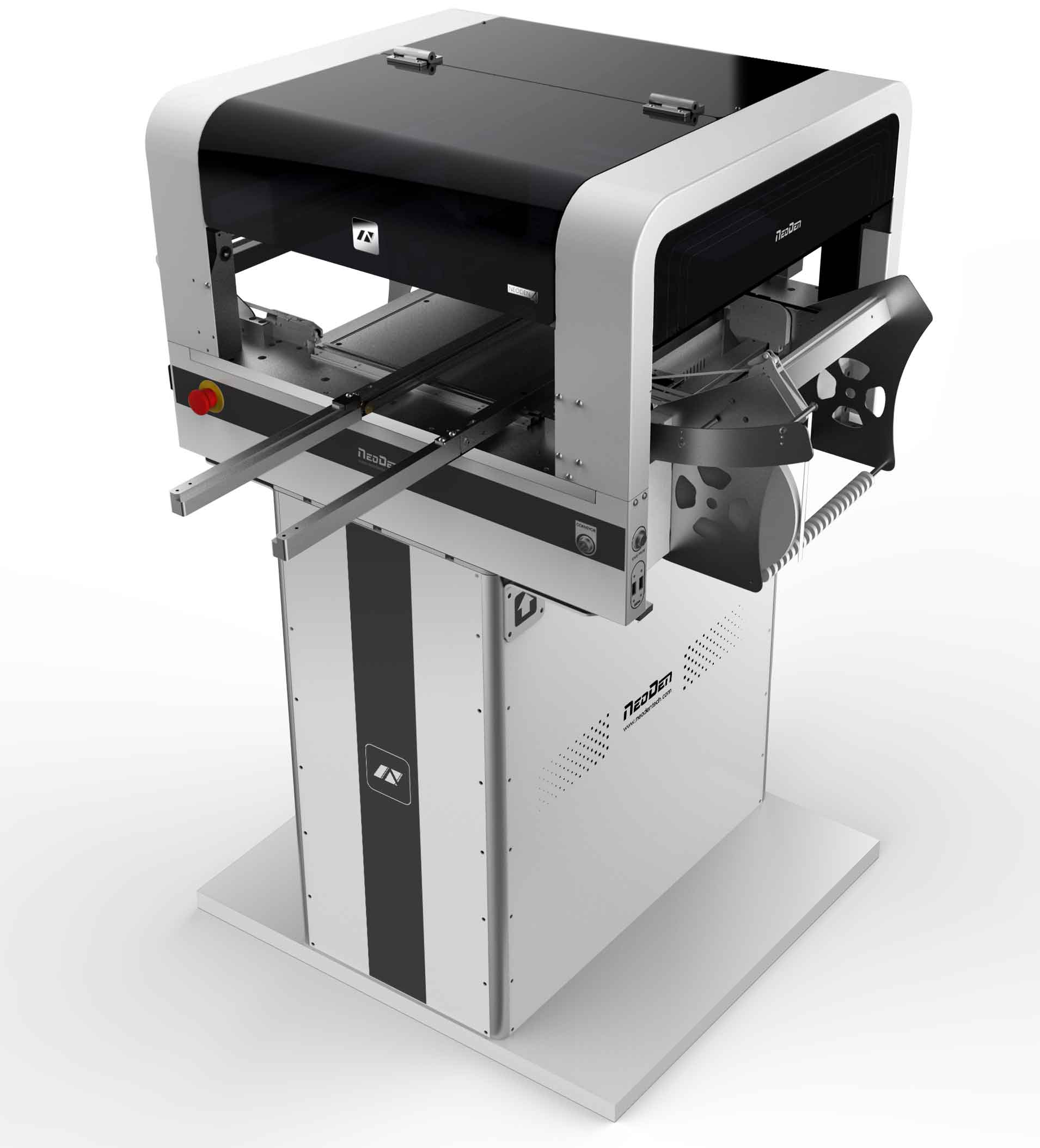

NeoDen PCB Pick and Place Machine

NeoDen PCB Pick and Place Machine

The fourth-generation model

Details

On-line dual rails

Deliver the finished board.

Accommodate different size boards.

Continuous automatic feeding the boards.

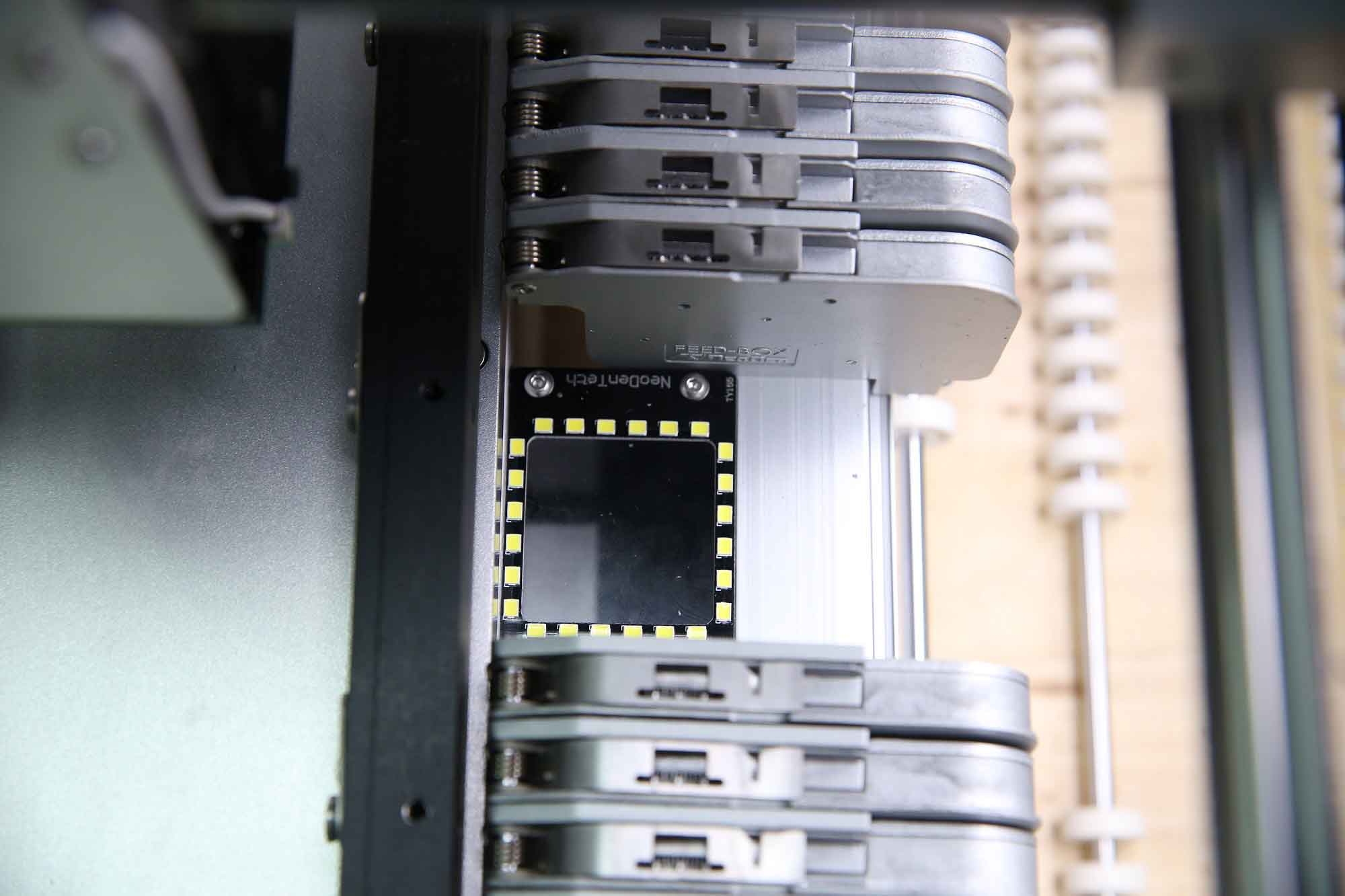

Vision system

Precisely aligned to the nozzles.

Corrects for small errors in component.

High-precision, two-camera vision system.

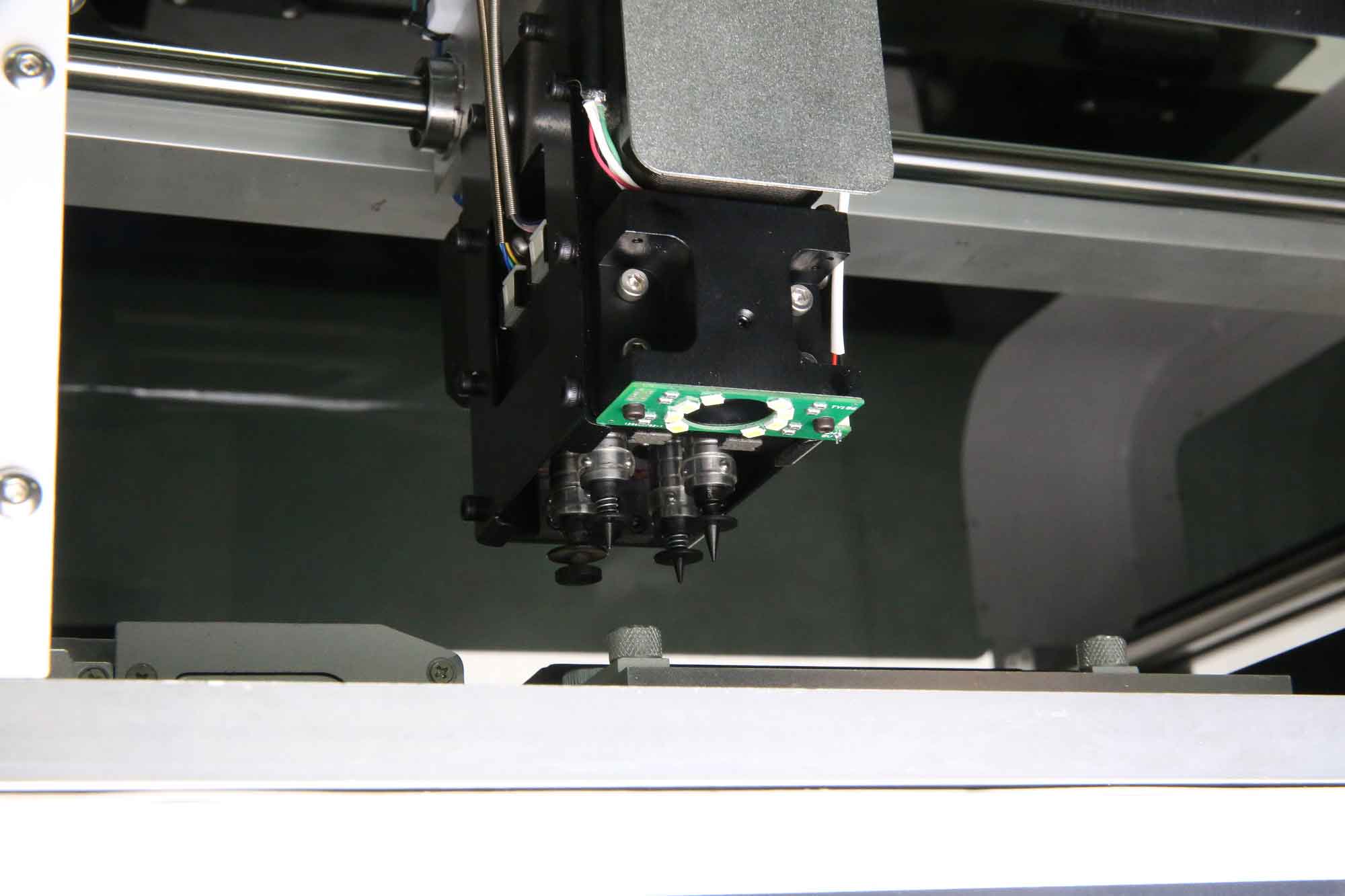

High precision nozzles

Four high precision mounting heads.

Any size nozzle can be installed.

360 degrees rotation at -180 to 180.

Electric tape-and-reel feeders

Electric tape-and-reel feeders

Accommodate up to 48 8mm tape-and-reel feeders

Any size feeder (8, 12, 16 and 24mm) can be installed in the machine

Specification

Product name: NeoDen PCB Pick and Place Machine

Machine Style: Single gantry with 4 heads

Placement Rate: 4000 CPH

External Dimension: L 870×W 680×H 480mm

Max applicable PCB: 290mm*1200mm

Feeders: 48pcs

Average working power: 220V/160W

Component Range: Smallest Size: 0201, Biggest Size: TQFP240, Max Height: 5mm

Package

If you need, please feel free to contact us for more information.

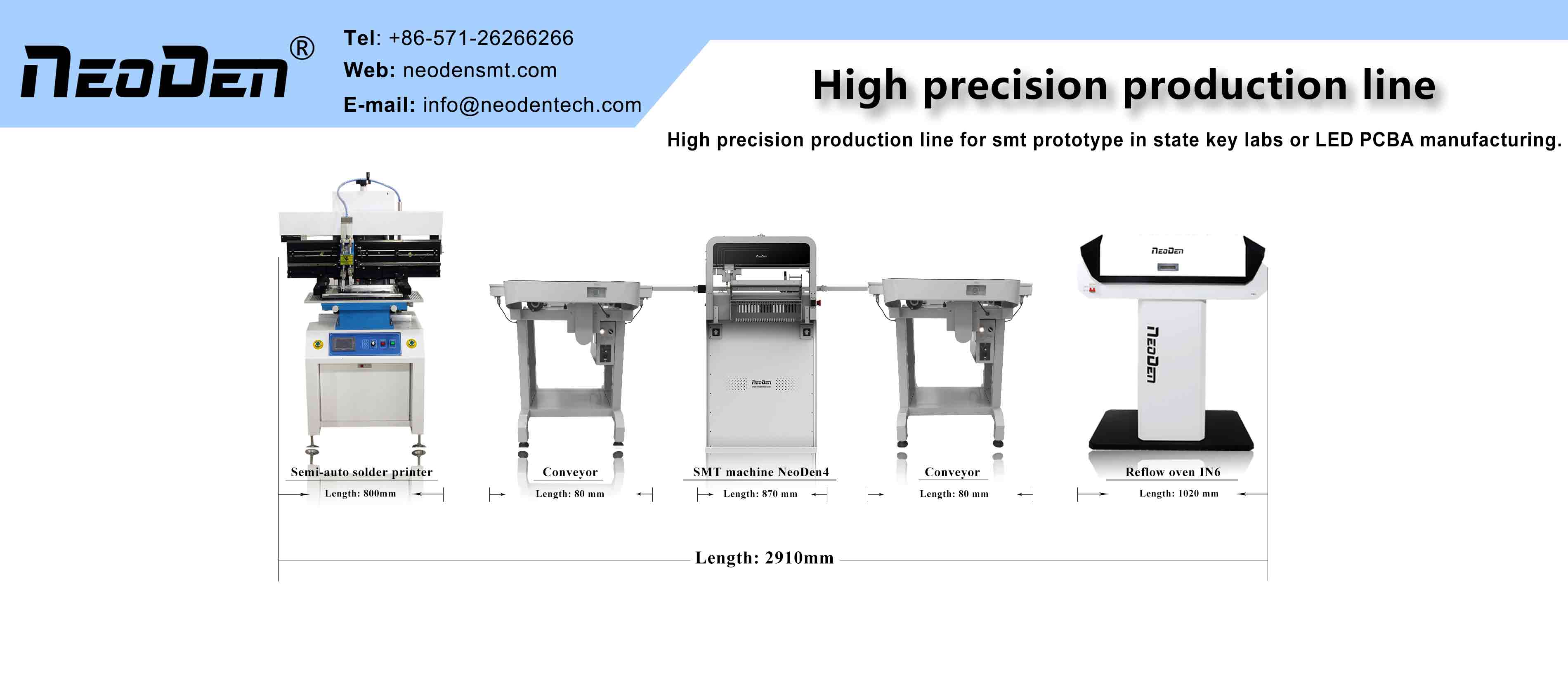

Rail system

Machines equipped with the auto-loading rail system can accommodate boards from to in width, and in length.

Even when the rail system is installed, any space left over on the table is still available for trays and short tapes.

The rail system allows automatic feeding of PCBs, automatic alignment of the board with the camera, and automatic ejection from the front of the machine or the rear.

Rear-ejection is useful when the machine is connected to an optional conveyor that can deliver the finished board directly to the reflow oven or to another NeoDen4.

About us

Factory

Zhejiang NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products.

In this decade, we independently developed NeoDen4, NeoDen IN6, NeoDen K1830, NeoDen FP2636 and other SMT products, which sold well all over the world. So far, we have sold more than 10,000pcs machines and exported them to over 130 countries around the world, establishing a good reputation in the market.

① Listed with CE and got 50+ patents

② Successful 10000+ customers across the globe

Certification

Exhibition

FAQ

Q1: When can I get the price?

A: Usually we quote within 8 hours after we get your inquiry.

Q2: How many workers in your factory?

A: More than 200 workers.

Q3: How far is your factory from the airport and train station?

A: From airport about 2 hours by car, and from train station about 30 minutes. We can pick up you.

One Stop SMT Equipments Manufacturer

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.