NeoDen PCB Component Placement Machine

NeoDen PCB Component Placement Machine

NeoDen PCB Component Placement Machine

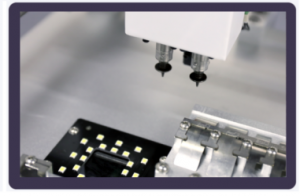

2 Heads, ±180° rotation head system

Small volume, low power

High speed and accuracy

Stable performance and easy operation

Specification

| Product Name | NeoDen PCB Component Placement Machine |

||

| Machine Style | Single Gantry with 2 heads | Model | NeoDen 3V-Advanced |

| Placement Rate | 3,500CPH Vision on/5,000CPH Vision off | Placement Accuracy | +/-0.05mm |

| Feeder Capacity | Max Tape Feeder: 44pcs (All 8mm width) | Alignment | Stage Vision |

| Vibration Feeder: 5 | Component Range | Smallest Size: 0402 | |

| Tray Feeder: 10 | Biggest Size: TQFP144 | ||

| Rotation | +/-180° | Max Height: 5mm | |

| Electricity Supply | 110V/220V | Max Board Dimension | 320x390mm |

| Power | 160~200W | Machine Size | L820×W680×H410mm |

| Net Weight | 60Kg | Packing Size | L1010×W790×H580 mm |

Detail

2 heads

Full Vision 2 heads system

±180° rotation satisfy the need of wide range components

Patented Automatic Peel-box

Feeder Capacity: 44*Tape feeder(all 8mm),

5*Vibration feeder, 10* IC Tray feeder

Flexible PCB positioning

Using PCB support bars and pins,

wherever to put the PCB, whatever the shape of PCB.

Integrated Controller

More stable performance and easier to do maintenance.

NeoDen FP2636

1. Adjustable rubber footing, ensure the flatness while operating.

2. Rulers of stencil fixed frame for reference lines, ensure the levelness between stencil and PCB.

3. L supports and pins to fix PCB, applicable for multiple types PCBs’ fixation and printing, more flexible and convenient.

NeoDen IN6

1. Household power supply, convenient and practical.

2. ESD tray, easy to collect PCB after reflowing, convenient for R&D and prototype.

3. Reinforced heavy-duty carton package, light-weight and environment-friendly.

Click on the picture below to jump to the appropriate product:

About us

About us

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

In our global Ecosystem, we collaborate with our best partners to deliver a more closing sales service, high professional and efficient technical support.

① Established in 2010, 200+ employees, 8000+ Sq.m. factory

② 30+ Global Agents covered in Asia, Europe, America, Oceania and Africa

Certification

Exhibition

FAQ

Q1: Do you provide software updates?

A: Customers who buy our machine, we can offer free upgrades software for you.

Q2: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q3: How do I pay?

A: My friend, there are many ways. T/T(we prefer this one), Western Union, PayPal, choose your favorite one.

If you need, please feel free to contact us for more information!

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.