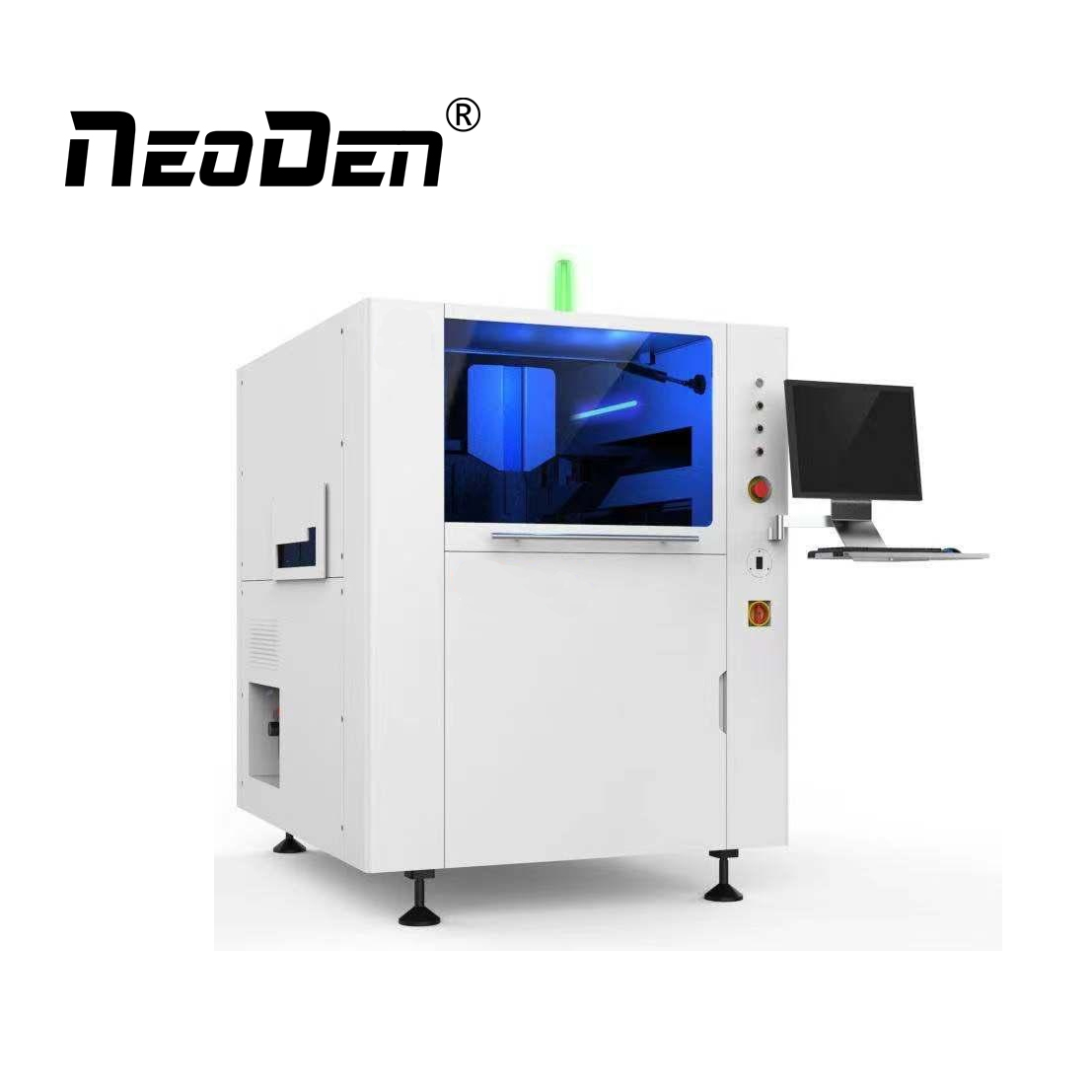

NeoDen ND1 SMD Solder Paste Printer

NeoDen ND1 SMD Solder Paste Printer

Specification

| Product name | NeoDen ND1 SMD Solder Paste Printer |

| Maximum board size(X x Y) | 450mm x 350mm |

| Minimum board size(X x Y) | 50mm x 50mm |

| PCB thickness | 0.6mm~14mm |

| Warpage | ≤1% Diagonal |

| Maximum board weight | 10Kg |

| Board margin gap | Configuration to 3mm |

| Maximum bottom gap | 20mm |

| Transfer speed | 1500mm/s(Max) |

| Transfer height from the ground | 900±40mm |

| Transfer orbit direction | L-R, R-L, L-L, R-R |

| Machine weight | Appro.1000Kg |

Maintain

I. Printing part

1. Check whether there are residues of solder paste on the printing table.

2. Use a clean cotton cloth with a little alcohol to do the necessary cleaning.

3. Check the transmission system and positioning clamping parts on whether there are residues of solder paste.

4. Take off the cover around the table and clean the guide rod and linear guide with clean cotton cloth.

5. Lubricate the guiding screw and linear guide with special lubricant for NSK guideway and screw.

6. Clean the sensor with a cotton cloth with a little alcohol.

7. Adjust the synchronous belt in X and Y movement direction when needed.

8. Replace the cover plate.

II. The scraper system

1. Open the front cover of the machine.

2. Move the scraper beam to a suitable position, loosen the scraper head screw 1 to remove the scraper pressure plate.

3. Loosen the scraper pressure plate on the screw 2, remove the scraper blade.

4. with a cotton cloth with a little alcohol, clean the scraper platen and scraper blade.

5. Re-scraper pressure plate and scraper blade to the scraper head.

6. Such as scraper blade wear serious should be replaced.

Provide one-stop SMT assembly production line

Related products

About us

Factory

Established in 2010 with 100+ employees & 8000+ Sq.m. factory of independent property rights, to ensure the standard management and achieve the most economic effects as well as saving the cost.

40+ global partners covered in Asia, Europe, America, Oceania and Africa, to successfully serve 10000+ users in all of the world, to ensure the better and faster local service and prompt response.

3 different R&D teams with total 25+ professional R&D engineers, to ensure the better and more advanced developments and new innovation.

Skilled and professional english support&service engineers, to ensure the prompt response within 8 hours, solution provides within 24 hours.

Certification

Exhibition

FAQ

Q1: Are you trading company or manufacturer?

A: We are professional manufacturer specialized in SMT production line.

And we trade our products with our clients directly.

Q2: What’s is your shipping service?

A: We can provide services for vessel booking, goods consolidation, customs declaration, shipping documents preparation and delivery bulk at the shipping port.

Q3: What about the lead time for mass production?

A: Honestly, it depends on the order quantity and the season you place the order.

Alway 15-30 days based on general order.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.