NeoDen LED PCB Assembly Machine

NeoDen LED PCB Assembly Machine video

NeoDen LED PCB Assembly Machine

Features

1. Machine runs on highly stable and secure Linux operating system.

2. Ethernet communication interface for all internal signal travel makes the machine to perform more stable and flexible.

3. Picking location of pneumatic feeder can be calibrated automatically and promptly,to ensure easy operation and high efficiency.

Specification

Product name: NeoDen LED PCB Assembly Machine

Model: NeoDen K1830

Tape width: 8mm, 12mm, 16mm, 24mm, 32mm, 44mm,56mm

IC Tray Capacity: 10

Smallest Component size: 0201 (electronic feeder)

Applicable Components: 0201, Fine-pitch IC, Led Component, Diode, Triode

Component Height Maximum: 18mm

Applicable PCB size: 540mm*300mm (1500 optinal)

Power Supply: 220V, 50Hz (convertible to 110V)

Air source: 0.6MPa

N.W./G.W: 280/360Kgs

Product Detail

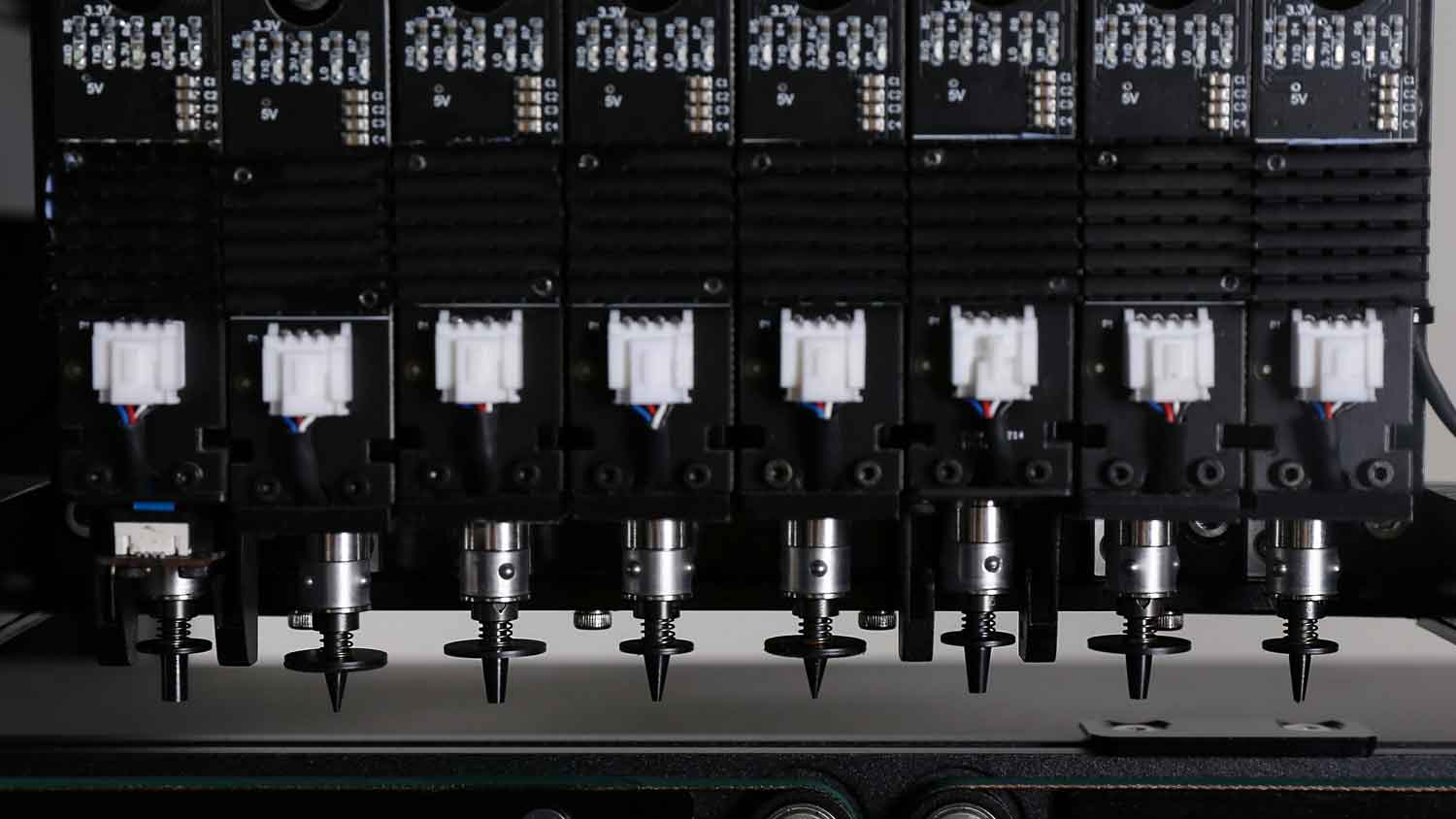

8 heads with Vision enabled

Rotation: +/-180 (360)

High speed repeatable placement accuracy

66 Reel tape feeders

Be calibrated automatically and promptly

Ensure easy operation and high efficiency

Double mark cameras

Better calibration

Improves the overall speed of the machine

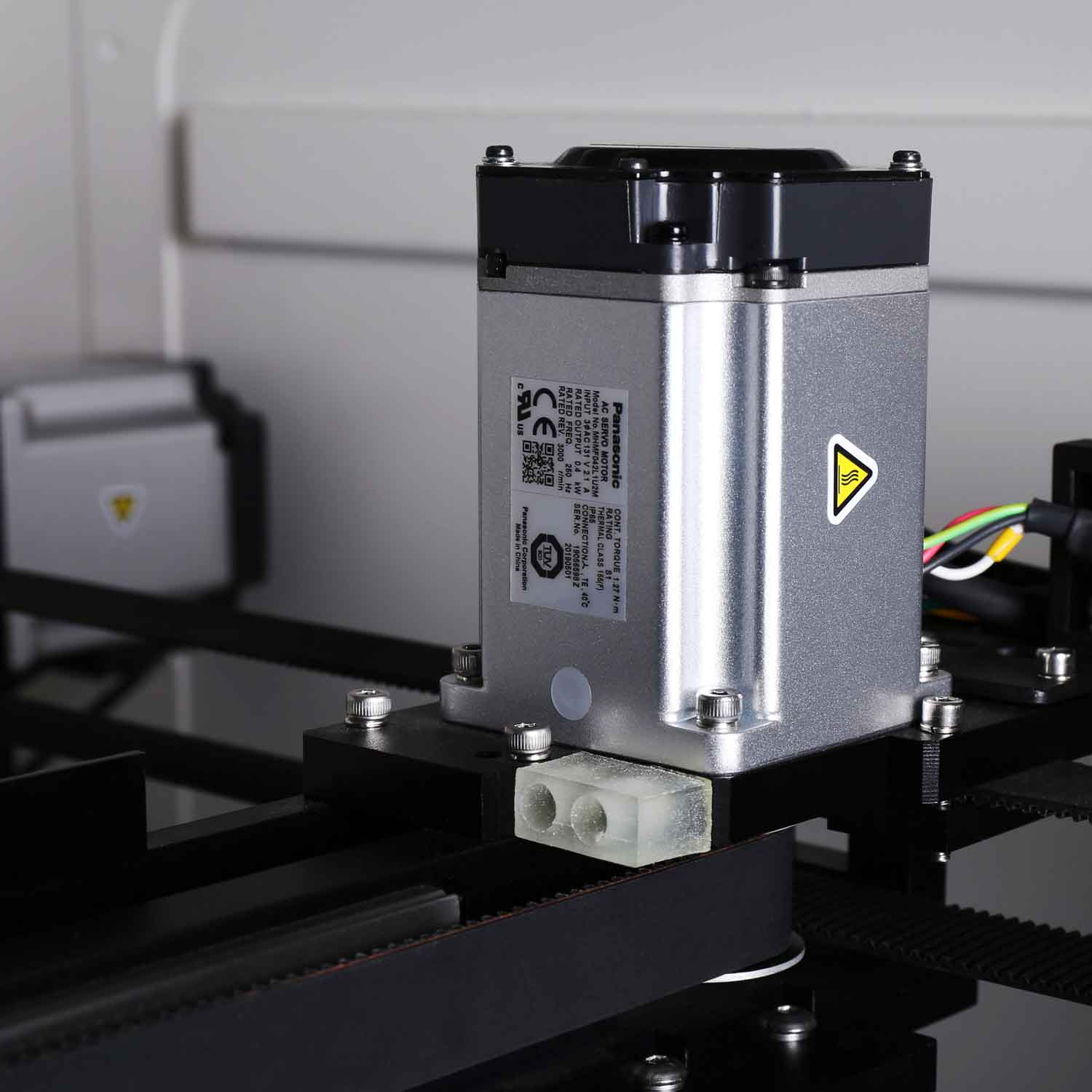

Drive Motor

Panasonic Servo Motor A6

Make the machine to function more accurate

High-definition display

Display size: 12 inch

Makes the machine more convenient to use

Warning light

Triple color of light

Beautiful and elegant indicator design

If you need, please feel free to contact us for more information.

Manual Test

1. Nozzle Replace: click to replace nozzles, the head will move to its position for easier replacement.

2. Head Nozzle: click to test rotation, suction, blow and moving down functions of nozzle NO.1-NO.8.

3. Width Set: after the initialization of rails width, enter the expected width, click width set, the rails be widened accordingly.

4. PCB Raise Initialize: initialize the PCB raise function.

5. Width Initialize: initialize the width of rails back to zero.

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist everywhere.

① Established in 2010, 200+ employees, 8000+ Sq.m. factory

② Successful 10000+ customers across the globe

③ 30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours

Certification

Exhibition

FAQ

Q1: How can I buy machine from you?

A: (1) Consult us on line or by e-mail.

(2) Negotiate and confirm the final price , shipping , payment method and other terms.

(3) Send you the perfroma invoice and confirm your order.

(4) Make the payment according to the method put on proforma nvoice.

(5) We prepare your order in terms of the proforma invoice after confirming your full payment. And 100% quality check before shipping.

(6) Send your order via express or by air or by sea.

Q2: How many square meters of your factory?

A: More than 8,000 square meter.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.