NeoDen K1830 PCB Pick and Place Machine

NeoDen K1830 PCB Pick and Place Machine video

NeoDen K1830 PCB Pick and Place Machine

Features

1. High resolution and high speed component camera system improves the overall speed of the machine.

2. Ethernet communication interface for all internal signal travel makes the machine to perform more stable and flexible.

3. PCB location can be calibrated automatically and promptly,based on the correct and specific placement request.

Specification

Product name: NeoDen K1830 PCB Pick and Place Machine

Model: NeoDen K1830

Tape width: 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, 56mm

IC Tray Capacity: 10

Smallest Component size: 0201 (electronic feeder)

Applicable Components: 0201, Fine-pitch IC, Led Component, Diode, Triode

Component Height Maximum: 18mm

Applicable PCB size: 540mm*300mm (1500 optinal)

Power Supply: 220V, 50Hz (convertible to 110V)

Air source: 0.6MPa

N.W./G.W: 280/360Kgs

Product Detail

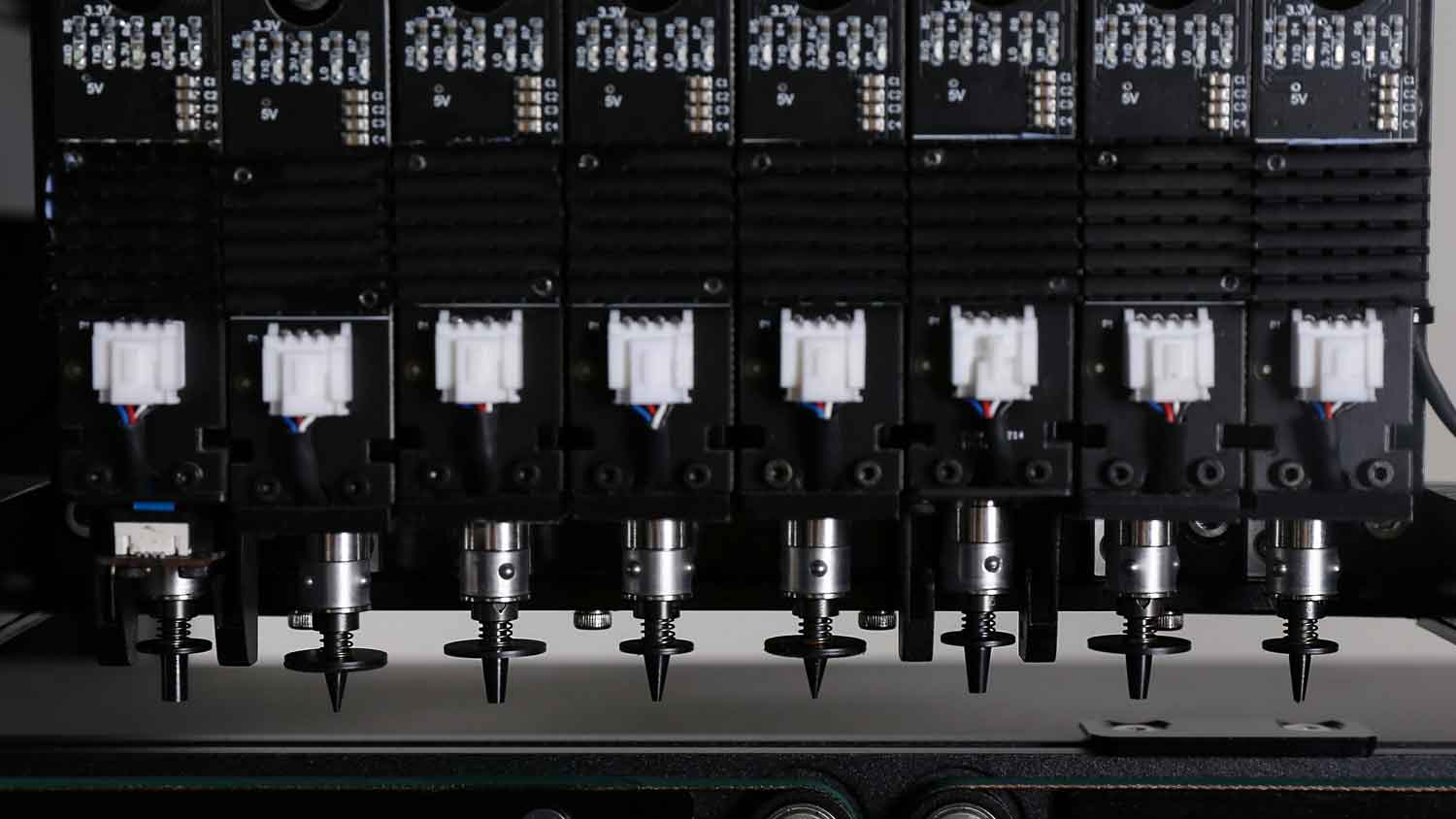

8 heads with Vision enabled

Rotation: +/-180 (360)

Max Placement Speed: 16,000 CPH

66 Reel tape feeders

Be calibrated automatically and promptly

Ensure easy operation and high efficiency

Double mark cameras

Better calibration

Improves the overall speed of the machine

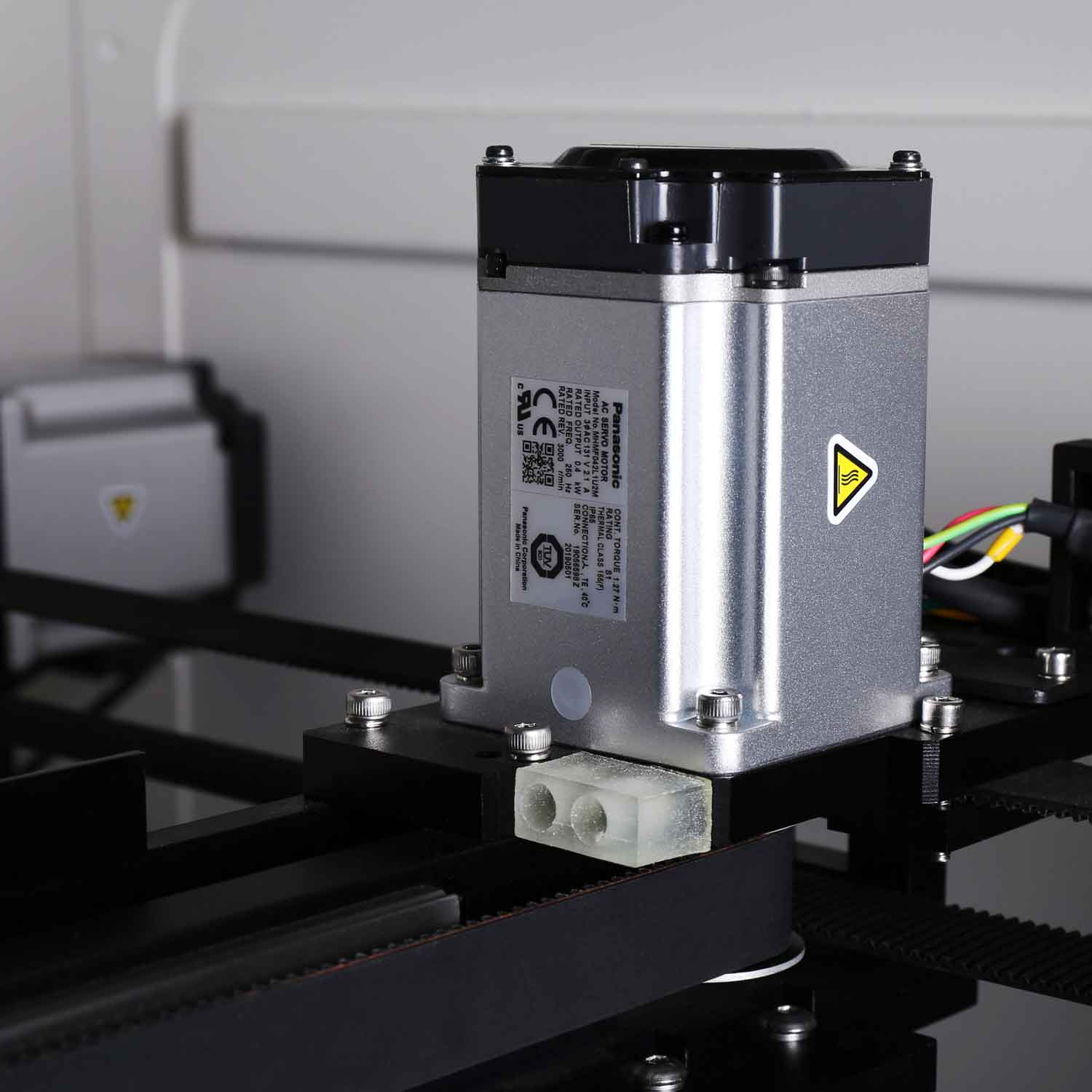

Drive Motor

Panasonic Servo Motor A6

Make the machine to function more accurate

High-definition display

Display size: 12 inch

Makes the machine more convenient to use

Warning light

Triple color of light

Beautiful and elegant indicator design

If you need, please feel free to contact us for more information.

Suggestions on production process

1. First component confirmation: confirm the component angle and polarity, component picking position and mounting position.

2. Start production after confirming solder paste printing and temperature setting.

Disconnect the electricity supply after the system being powered off.

Keep the machine clean, daily maintenance of the nozzles assures high utility.

About us

Factory

3 different R&D teams with total 25+ professional R&D engineers, to ensure the better and more advanced developments and new innovation.

Skilled and professional english support&service engineers, to ensure the prompt response within 8 hours, solution provides within 24 hours.

The unique one among all of the Chinese manufacturers who registered and approved CE by TUV NORD.

Certification

Exhibition

FAQ

Q1: Can l visit your factory?

A:By all means, we warmly welcome your arrival, Before you take off from your country, please let us know.

We will show you the way and arrange time to pick you up if possible.

Q2: Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

Q3: What is your advantage compared with your competitors?

A: (1). Qualified Manufacturer

(2). Reliable Quality Control

(3). Competitive Price

(4). High Efficiency working (24*7hours)

(5). One-Stop Service

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.