NeoDen IN6 SMT Soldering Machine

NeoDen IN6 SMT Soldering Machine

Original high-performance aluminum alloy heating plate instead of heating pipe, both energy-saving and high-efficient, and transverse temperature difference is less than 2℃.

Japan NSK hot-air motor bearings and Swiss heating wire, durable and stable.

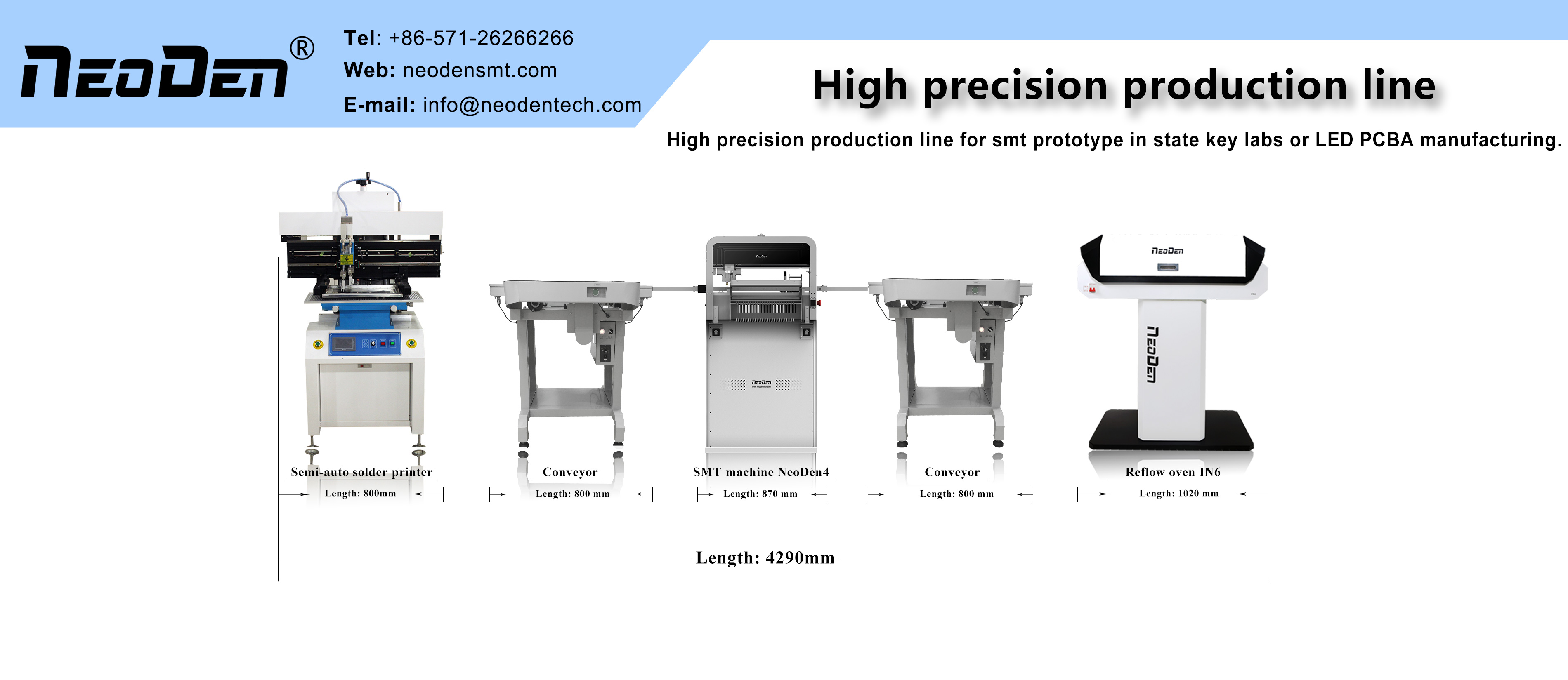

The table-top design of the product makes it a perfect solution for production lines with versatile requirements.

It is designed with internal automation that helps operators provide streamlined soldering.

Specification

| Product Name | NeoDen IN6 SMT Soldering Machine |

| Power requirement | 110/220VAC 1-phase |

| Power max. | 2KW |

| Heating zone quantity | Upper3/ down3 |

| Conveyor speed | 5 - 30 cm/min (2 - 12 inch/min) |

| Standard Max Height | 26mm |

| Temperature control range | Room temperature~300 degree celsius |

| Temperature control accuracy | ±0.2 degree celsius |

| Temperature distribution deviation | ±1 degree celsius |

| Soldering width | 260 mm (10 inch) |

| Length process chamber | 680 mm (26.8 inch) |

| Heat-up time | approx. 25 min |

| Dimensions | 1020*507*350mm(L*W*H) |

| Packing Size | 112*62*56cm |

| N.W./ G.W. | 49KG/64kg (without working table) |

Detail

Heating zones

6 zones design, (3 top|3 bottom)

Full hot-air convection

Intelligent control system

Several working files can be stored

Color touch screen

Saving energy and Eco-friendly

Built-in solder smoke filtering system

Reinforced heavy-duty carton package

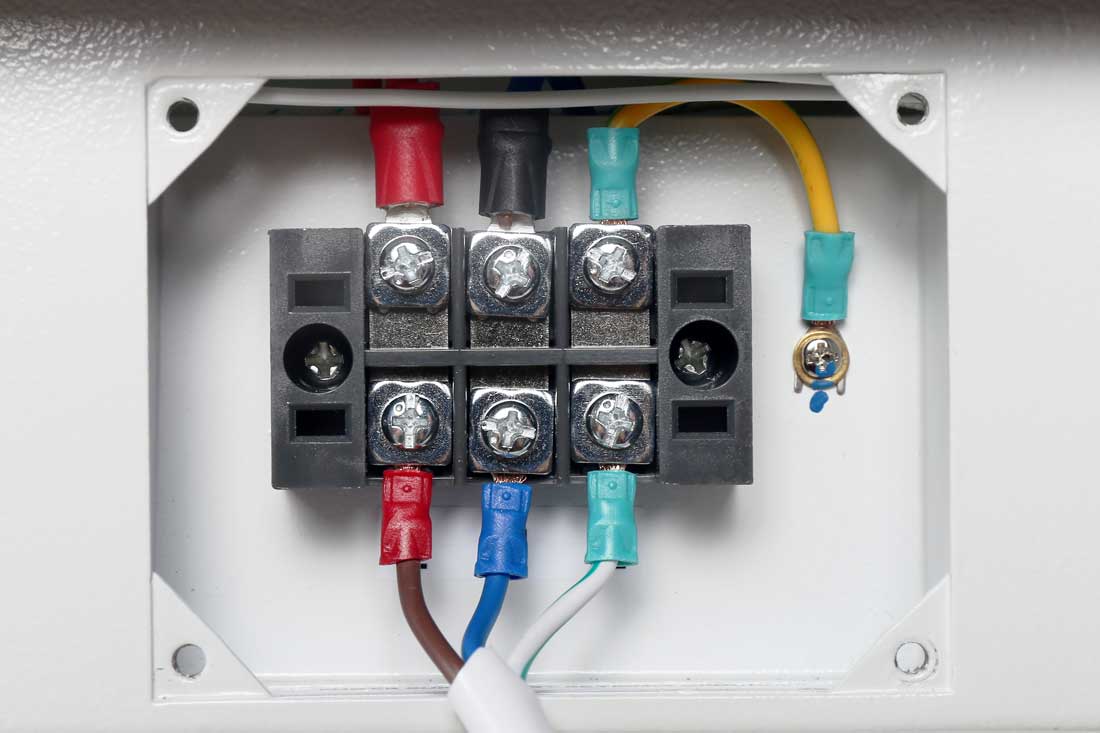

Power Supply Connection

Power supply requirement:110V/220V

Stay away from flammable and explosive

Installation Attentions

♦ Power supply requirement: 110V/220V.

♦ For desktop reflow oven, should be working on workbench, don’t suggest to use wooden material.

♦ The machine should be set in standard SMT workshop, stay away from flammable and explosive if couldn’t meet previous requirements.

♦ Exposed wire harness should be well protected, prohibit to expose at the passage or flue in case of causing any accident.

Status of Indicators

There is a green bar indicator at the PCB entrance that indicates whether the temperature in all zones has reached the set temperature.

This indicator lights up when the actual temperature of all zones reaches the set temperature.

FAQ

Q1: Can you do OEM and ODM?

A: Yes, OEM and ODM are both acceptable.

Q2: Which payment form you can accept?

A: T/T, Western Union, PayPal etc.

We accept any convenient and swift payment term.

Q3: How many square meters of your factory?

A: More than 8,000 square meter.

About us

Factory

Certification

Exhibition

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.