NeoDen IN6 Reflow Soldering Station

NeoDen IN6 Reflow Soldering Station

Original high-performance aluminum alloy heating plate instead of heating pipe, both energy-saving and high-efficient, and transverse temperature difference is less than 2℃.

PCB soldering temperature curve can be displayed based on real-time measurement

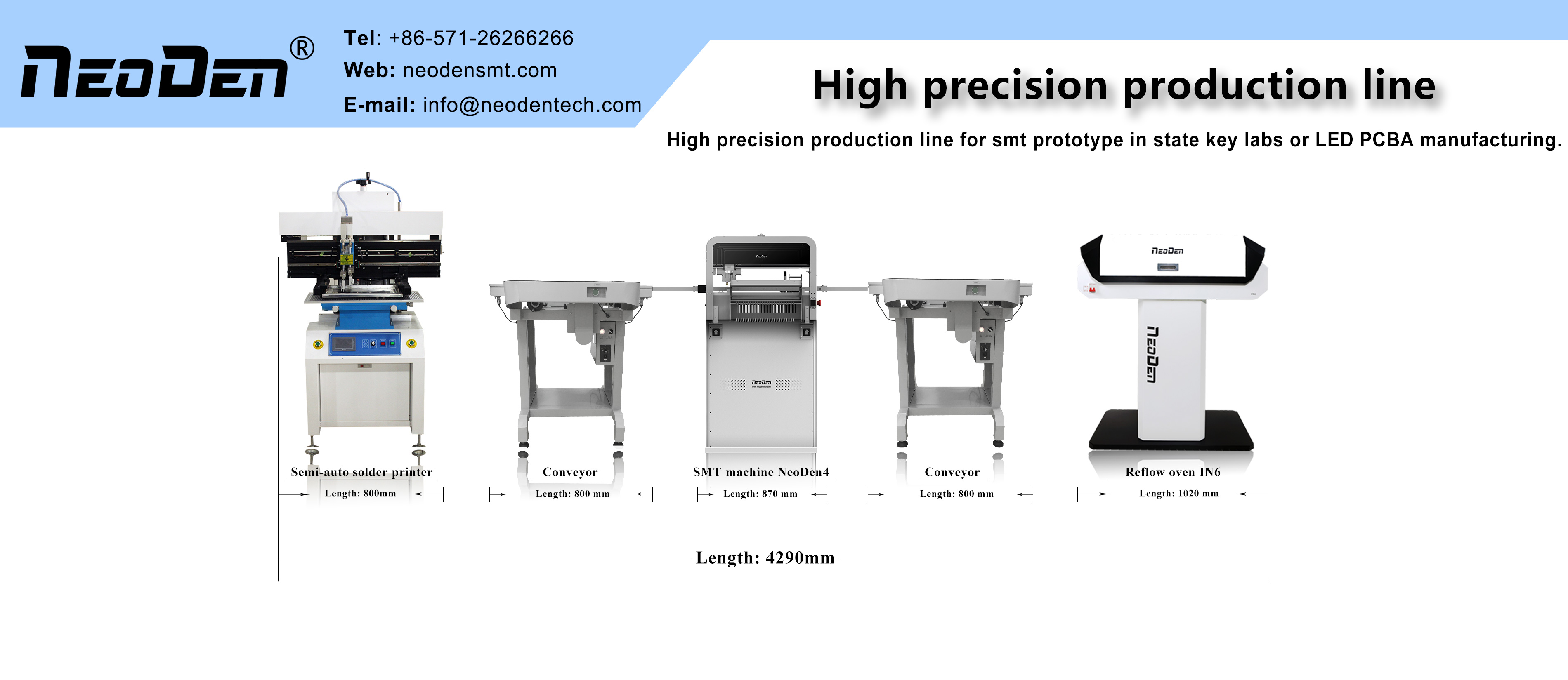

The table-top design of the product makes it a perfect solution for production lines with versatile requirements. It is designed with internal automation that helps operators provide streamlined soldering.

Temperature can be controlled with extreme accuracy—users can pinpoint heat within 0.2°C.

The NeoDen IN6 is built with an aluminum alloy heating chamber.

Specification

| Product Name | NeoDen IN6 Reflow Soldering Station |

| Power requirement | 110/220VAC 1-phase |

| Power max. | 2KW |

| Heating zone quantity | Upper3/ down3 |

| Conveyor speed | 5 - 30 cm/min (2 - 12 inch/min) |

| Standard Max Height | 26mm |

| Temperature control range | Room temperature~300 degree celsius |

| Temperature control accuracy | ±0.2 degree celsius |

| Temperature distribution deviation | ±1 degree celsius |

| Soldering width | 260 mm (10 inch) |

| Length process chamber | 680 mm (26.8 inch) |

| Heat-up time | approx. 25 min |

| Dimensions | 1020*507*350mm(L*W*H) |

| Packing Size | 112*62*56cm |

| N.W./ G.W. | 49KG/64kg (without working table) |

Detail

Heating zones

6 zones design, (3 top|3 bottom)

Full hot-air convection

Intelligent control system

Several working files can be stored

Color touch screen

Saving energy and Eco-friendly

Built-in solder smoke filtering system

Reinforced heavy-duty carton package

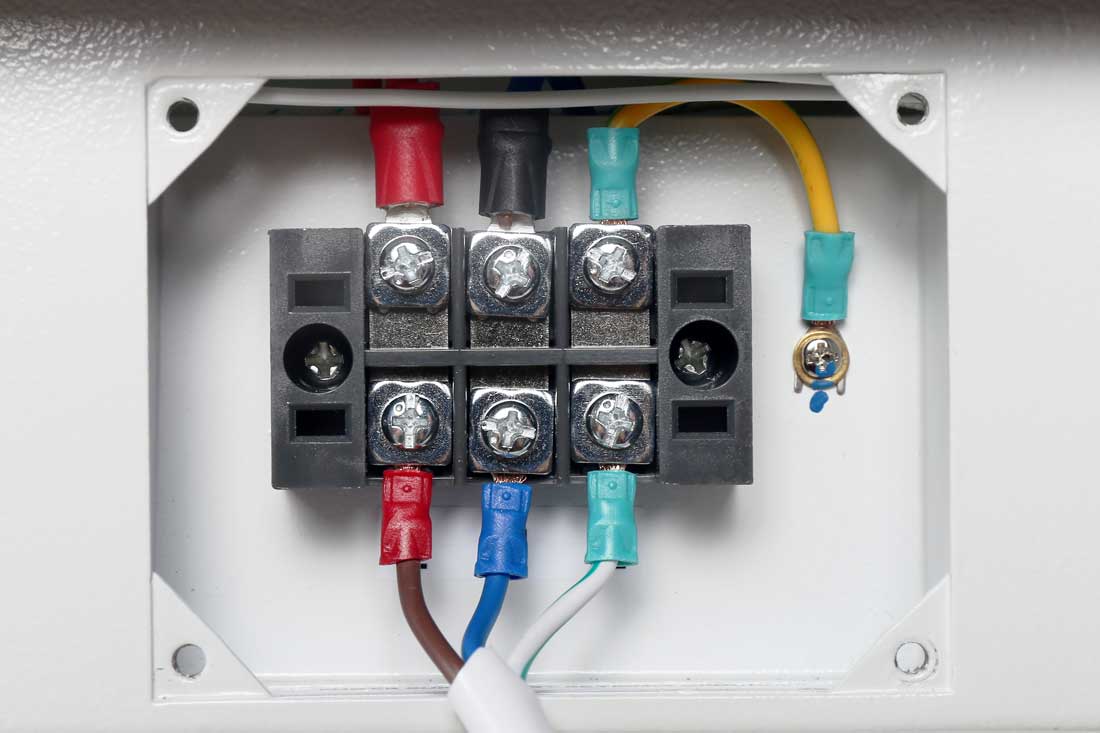

Power Supply Connection

Power supply requirement:110V/220V

Stay away from flammable and explosive

Details about temperature area setting

Set the temperature and belt speed to initial value, to the cooling oven, should be preheated for 25 minutes.

When the temperature is stable, let PCB pass heat reflow system. If there is no reflow, can properly reduce the transfer chain rotation speed. Another way is that, do not adjust the speed, and increase the temperature properly. When adjust the temperature, notice that it cannot exceed the PCB and component bearing capacity.

Let the PCB pass the reflow system in the new speed or new set temperature. If there is no reflow, turn to redo the above step. Otherwise, need temperature fine-turning.

The heat temperature wave is adjustable according to the PCB. You can adjust the transfer chain rotation speed to adjust the temperature. Reduce the transfer chain rotation speed can increase the product heat temperature. On the contrary, you can reduce the product heat temperature.

FAQ

Q1: Which payment form you can accept?

A: T/T, Western Union, PayPal etc. We accept any convenient and swift payment term.

Q2: Is there the products tested before shipping?

A: Yes, of course. All of our conveyor belt we all will has been 100% QC before shipping. We test every batch every day.

Q3: What is your advantage compared with your competitors?

A: (1). Qualified Manufacturer

(2). Reliable Quality Control

(3). Competitive Price

(4). High Efficiency working (24*7hours)

(5). One-Stop Service

About us

Factory

Zhejiang NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products. We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist on everywhere.

40+ global partners covered in Asia, Europe, America, Oceania and Africa, to successfully serve 10000+ users in all of the world, to ensure the better and faster local service and prompt response.

NeoDen supplies life-long technical support and service for all of the NeoDen machines, moreover, regular software updates based on the using experiences and actual daily request from the endusers.

Certification

Exhibition

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.