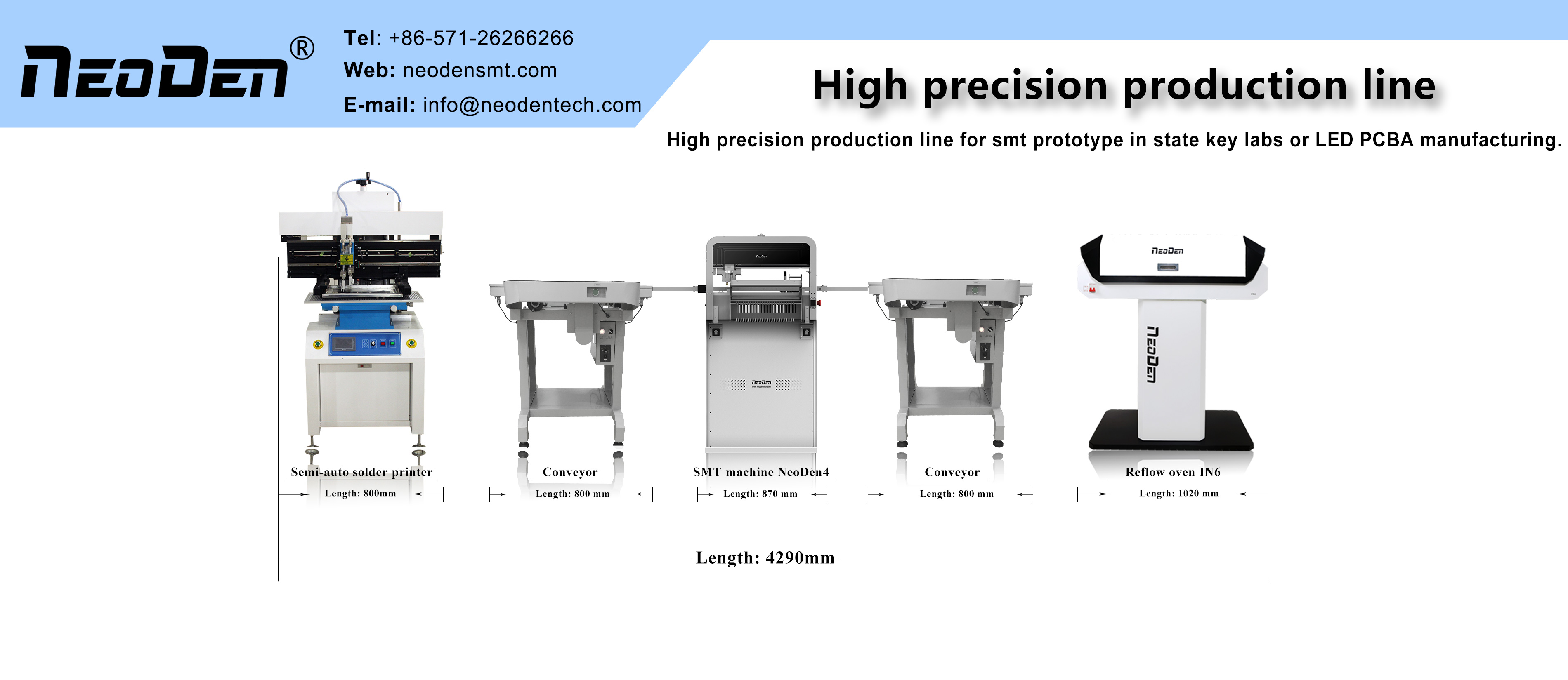

NeoDen IN6 Reflow Soldering Machine

NeoDen IN6 Reflow Soldering Machine

ESD tray, easy to collect PCB after reflowing, convenient for R&D and prototype.

PCB soldering temperature curve can be displayed based on real-time measurement.

Working files are storable within the oven, and both Celsius and Fahrenheit formats are available to users.

The oven uses a 110/220V AC power source and has a gross weight (G1) of 57kg.

Specification

| Product Name | NeoDen IN6 Reflow Soldering Machine |

| Power requirement | 110/220VAC 1-phase |

| Power max. | 2KW |

| Heating zone quantity | Upper3/ down3 |

| Conveyor speed | 5 - 30 cm/min (2 - 12 inch/min) |

| Standard Max Height | 30mm |

| Temperature control range | Room temperature~300 degree celsius |

| Temperature control accuracy | ±0.2 degree celsius |

| Temperature distribution deviation | ±1 degree celsius |

| Soldering width | 260 mm (10 inch) |

| Length process chamber | 680 mm (26.8 inch) |

| Heat-up time | approx. 25 min |

| Dimensions | 1020*507*350mm(L*W*H) |

| Packing Size | 112*62*56cm |

| N.W./ G.W. | 49KG/64kg (without working table) |

Detail

Heating zones

6 zones design, (3 top|3 bottom)

Full hot-air convection

Intelligent control system

Several working files can be stored

Color touch screen

Saving energy and Eco-friendly

Built-in solder smoke filtering system

Reinforced heavy-duty carton package

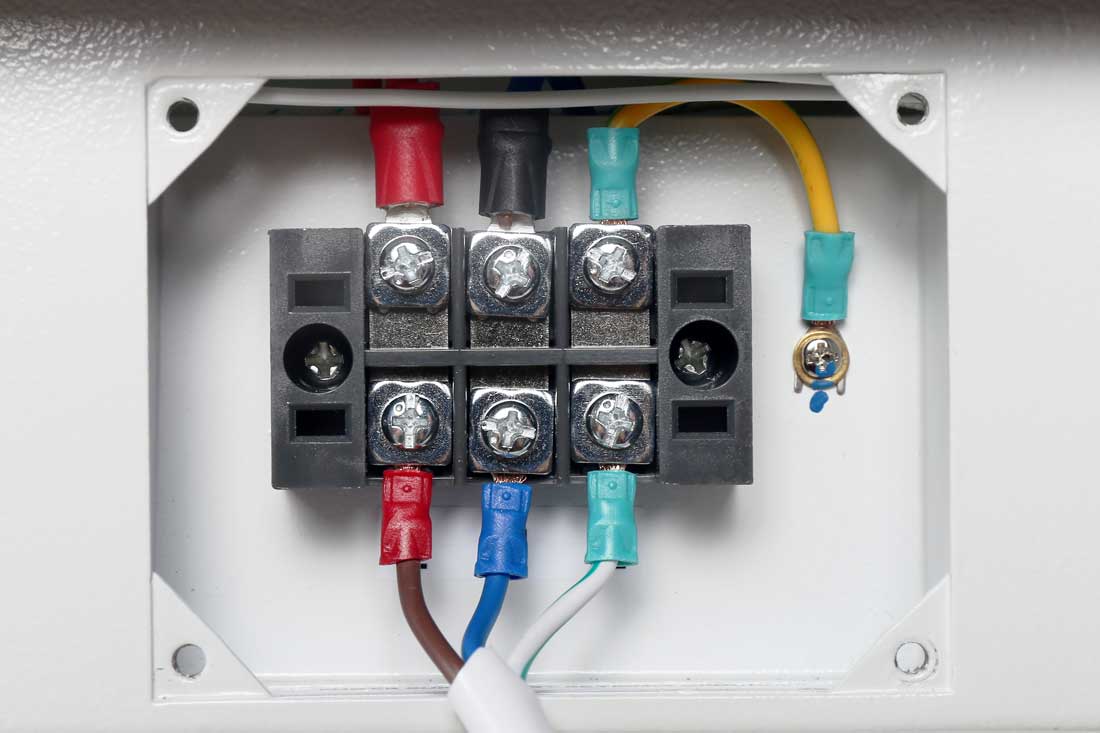

Power Supply Connection

Power supply requirement:110V/220V

Stay away from flammable and explosive

Installation Attentions

♦ Power supply requirement: 110V/220V.

♦ For desktop reflow oven, should be working on workbench, don’t suggest to use wooden material.

♦ The machine should be set in standard SMT workshop, stay away from flammable and explosive if couldn’t meet previous requirements.

♦ Exposed wire harness should be well protected, prohibit to expose at the passage or flue in case of causing any accident.

Status of Indicators

There is a green bar indicator at the PCB entrance that indicates whether the temperature in all zones has reached the set temperature.

This indicator lights up when the actual temperature of all zones reaches the set temperature.

FAQ

Q1: How can I place an order?

A: You can contact any of our sales person for an order.

Please provide the details of your requirements as clear as possible.

So we can send you the offer at the first time.

For designing or further discussion, it is better to contact us with Skype, TradeManger or QQ or WhatsApp or other instant ways, in case of any delays.

Q2: What is your main market?

A: All over the world.

Q3: Do you have a export licence?

A: Yes.

About us

Factory

Quick facts about NeoDen

① Established in 2010, 200+ employees, 8000+ Sq.m. factory

② NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040

③ Successful 10000+ customers across the globe

④ 30+ Global Agents covered in Asia, Europe, America, Oceania and Africa

⑤ R&D Center: 3 R&D departments with 25+ professional R&D engineers

⑥ Listed with CE and got 50+ patents

⑦ 30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours

Certification

Exhibition

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.