NeoDen IN6 Hot Air Reflow Station

NeoDen IN6 Hot Air Reflow Station

Smart control with high sensitivity temperature sensor, the temperature can be stabilized within + 0.2℃.

Original high-performance aluminum alloy heating plate instead of heating pipe, both energy-saving and high-efficient, and transverse temperature difference is less than 2℃.

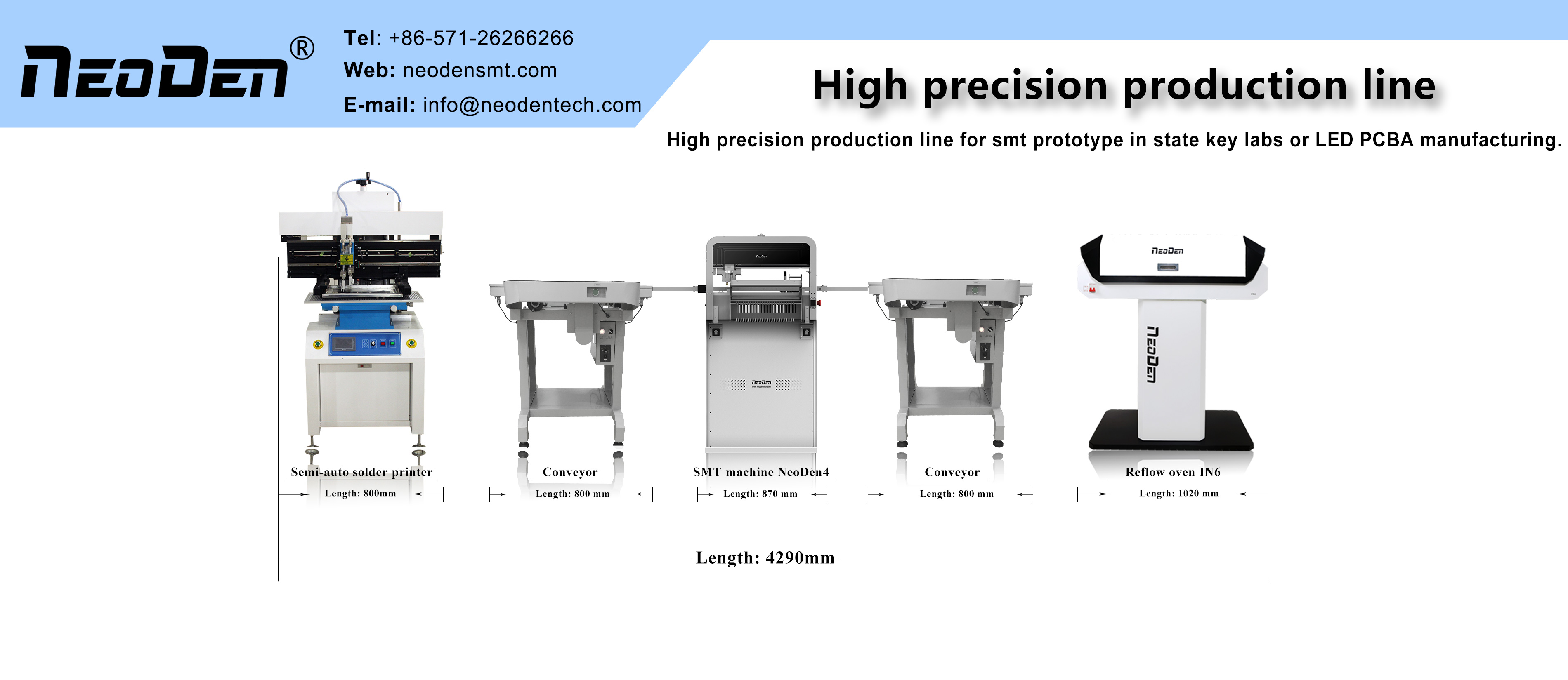

The table-top design of the product makes it a perfect solution for production lines with versatile requirements. It is designed with internal automation that helps operators provide streamlined soldering.

Working files are storable within the oven, and both Celsius and Fahrenheit formats are available to users. The oven uses a 110/220V AC power source and has a gross weight (G1) of 57kg.

Specification

| Product Name | NeoDen IN6 Hot Air Reflow Station |

| Power requirement | 110/220VAC 1-phase |

| Power max. | 2KW |

| Heating zone quantity | Upper3/ down3 |

| Conveyor speed | 5 - 30 cm/min (2 - 12 inch/min) |

| Standard Max Height | 26mm |

| Temperature control range | Room temperature~300 degree celsius |

| Temperature control accuracy | ±0.2 degree celsius |

| Temperature distribution deviation |

±1 degree celsius |

| Soldering width | 260 mm (10 inch) |

| Length process chamber | 680 mm (26.8 inch) |

| Heat-up time | approx. 25 min |

| Dimensions | 1020*507*350mm(L*W*H) |

| Packing Size | 112*62*56cm |

| N.W./ G.W. | 49KG/64kg (without working table) |

Detail

Heating zones

6 zones design, (3 top|3 bottom)

Full hot-air convection

Intelligent control system

Several working files can be stored

Color touch screen

Saving energy and Eco-friendly

Built-in solder smoke filtering system

Reinforced heavy-duty carton package

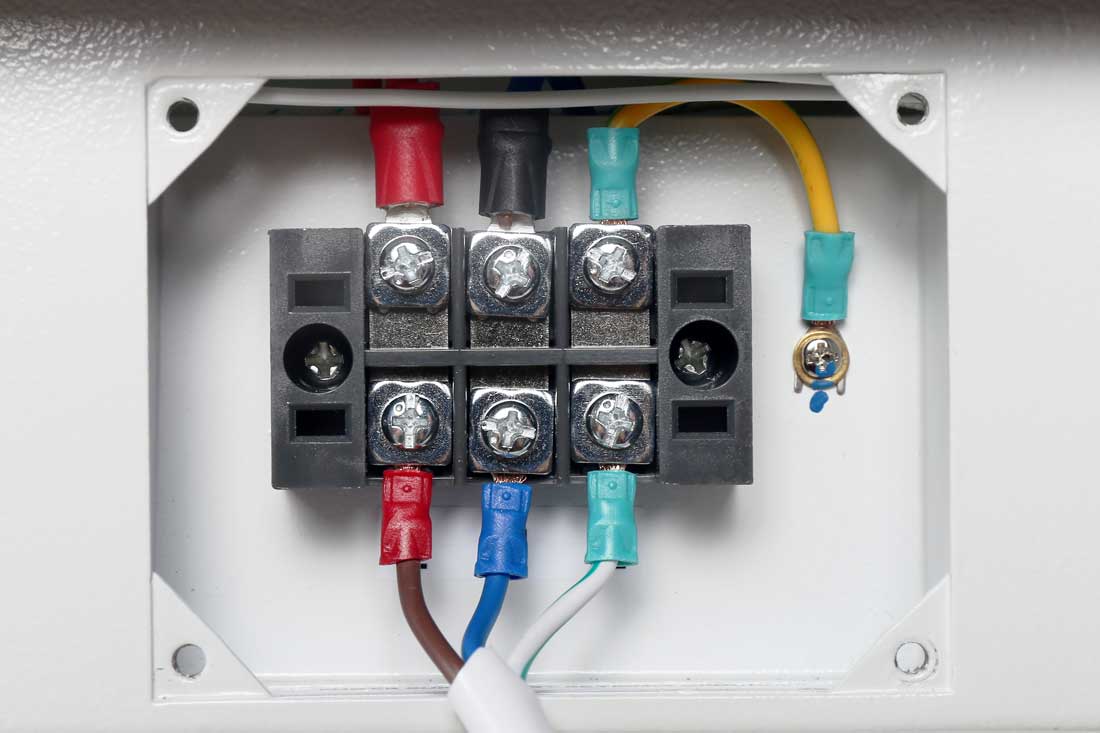

Power Supply Connection

Power supply requirement:110V/220V

Stay away from flammable and explosive

Quality control

We have QC person stay on the production lines do to the inspection.

All products must have been inspected before delivery.

We do inline inspection and final inspection.

1. All raw material checked once it arrive our factory.

2. All pieces and logo and all details checked during production.

3. All packing details checked during production.

4. All production quality and packing checked on final inspection after finished.

FAQ

Q1: May I know what’s the nearest airport from your company? in case I visit your company.

A: Hangzhou Airport is the nearest, welcome to visit us.

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry.

If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: How can I place an order?

A: You can contact any of our sales person for an order.

Please provide the details of your requirements as clear as possible.

So we can send you the offer at the first time.

For designing or further discussion, it is better to contact us with Skype, TradeManger or QQ or WhatsApp or other instant ways, in case of any delays.

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010.

With global presence in over 130 countries, the excellent performance, high accuracy and reliability of NeoDen PNP machines make them perfect for R&D, professional prototyping and small to medium batch production. We provide professional solution of one stop SMT equipment.

① R&D Center: 3 R&D departments with 25+ professional R&D engineers

② Listed with CE and got 50+ patents

Certification

Exhibition

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.