NeoDen IN6 Desktop Reflow Machine

NeoDen IN6 Desktop Reflow Machine

Heat insulation protection design, the casing temperature can be controlled within 40℃.

Household power supply, convenient and practical.

Approved by TUV CE, authoritative and reliable.

The new model has bypassed the need for a tubular heater, which provides even temperature distribution throughout the reflow oven.

By soldering PCBs in even convection, all components are heated at the same rate.

Specification

| Product Name | NeoDen IN6 Desktop Reflow Machine |

| Power requirement | 110/220VAC 1-phase |

| Power max. | 2KW |

| Heating zone quantity | Upper3/ down3 |

| Conveyor speed | 5 - 30 cm/min (2 - 12 inch/min) |

| Standard Max Height | 26mm |

| Temperature control range | Room temperature~300 degree celsius |

| Temperature control accuracy | ±0.2 degree celsius |

| Temperature distribution deviation | ±1 degree celsius |

| Soldering width | 260 mm (10 inch) |

| Length process chamber | 680 mm (26.8 inch) |

| Heat-up time | approx. 25 min |

| Dimensions | 1020*507*350mm(L*W*H) |

| Packing Size | 112*62*56cm |

| N.W./ G.W. | 49KG/64kg (without working table) |

Detail

Heating zones

6 zones design, (3 top|3 bottom)

Full hot-air convection

Intelligent control system

Several working files can be stored

Color touch screen

Saving energy and Eco-friendly

Built-in solder smoke filtering system

Reinforced heavy-duty carton package

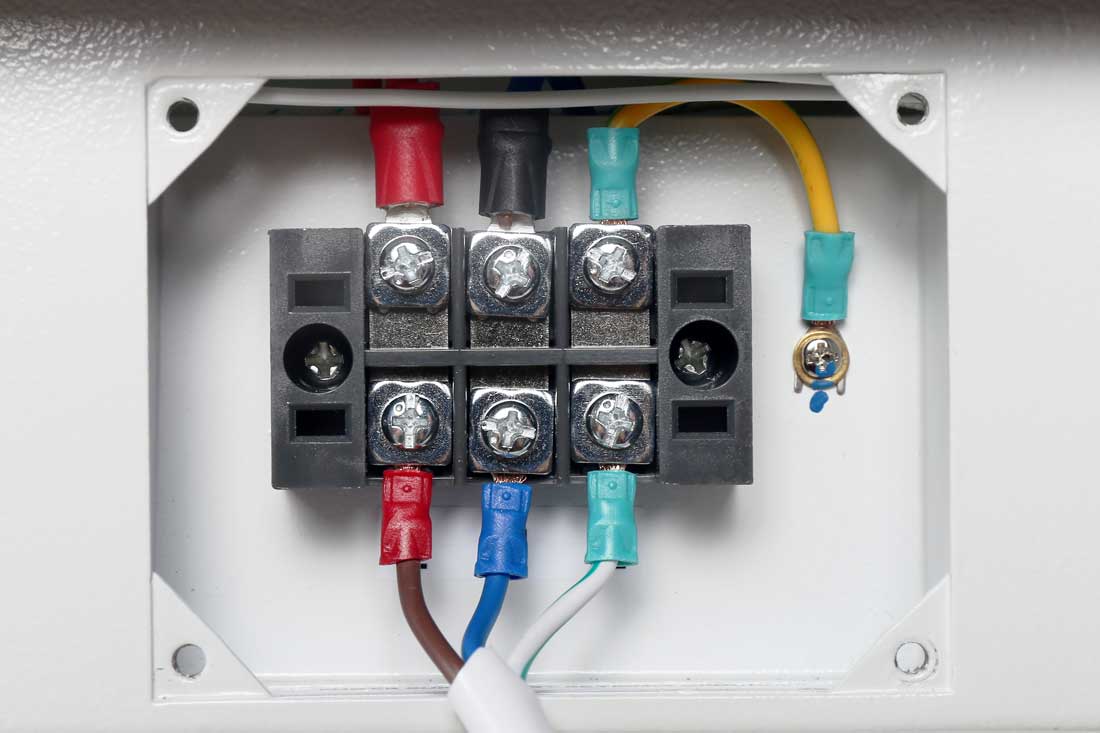

Power Supply Connection

Power supply requirement:110V/220V

Stay away from flammable and explosive

Brief Introduction

IN6 is a newly designed, environmentally friendly reflow oven with stable performance.

It can achieve full hot-air convection, excellent soldering performance.

It has 6 temperature zone, light and compact. Intelligent temperature control with high sensitivity temperature sensor, temperature can be stable within ±0.2°C.

It adopts Japan NSK hot air motor bearing and Swiss imported heating wire, which is durable and stable.

CE approved, provide authoritative quality assurance.

FAQ

Q1: Are you trading company or manufacturer?

A: We are professional manufacturer specialized in SMT production line.

And we trade our products with our clients directly.

Q2: Can you do OEM and ODM?

A: Yes, OEM and ODM are both acceptable.

Q3: When can I get the price?

A: Usually we quote within 8 hours after we get your inquiry.

About us

Factory

Zhejiang NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products. We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist on everywhere.

Established in 2010 with 100+ employees & 8000+ Sq.m. factory of independent property rights, to ensure the standard management and achieve the most economic effects as well as saving the cost;

Skilled and professional english support&service engineers, to ensure the prompt response within 8 hours, solution provides within 24 hours.

Certification

Exhibition

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.