NeoDen IN12C SMT Reflow Machine

NeoDen IN12C SMT Reflow Machine

Specification

| Product name | NeoDen IN12C SMT Reflow Machine |

| Model | NeoDen IN12C |

| Heating Zone Quantity | Upper6 / Down6 |

| Cooling Fan | Upper4 |

| Conveyor Speed | 50~600 mm/min |

| Temperature Range | Room temperature~300℃ |

| Temperature Accuracy | 1℃ |

| PCB Temperature Deviation | ±2℃ |

| Max soldering height (mm) | 35mm (includes PCB thickness) |

| Max Soldering Width (PCB Width) | 350mm |

| Length Process Chamber | 1354mm |

| Electricity Supply | AC 220v/single phase |

| Machine Size | L2305mm×W612mm×H1230mm |

| Heat-up Time | 30 min |

| Net Weight | 300Kgs |

Details

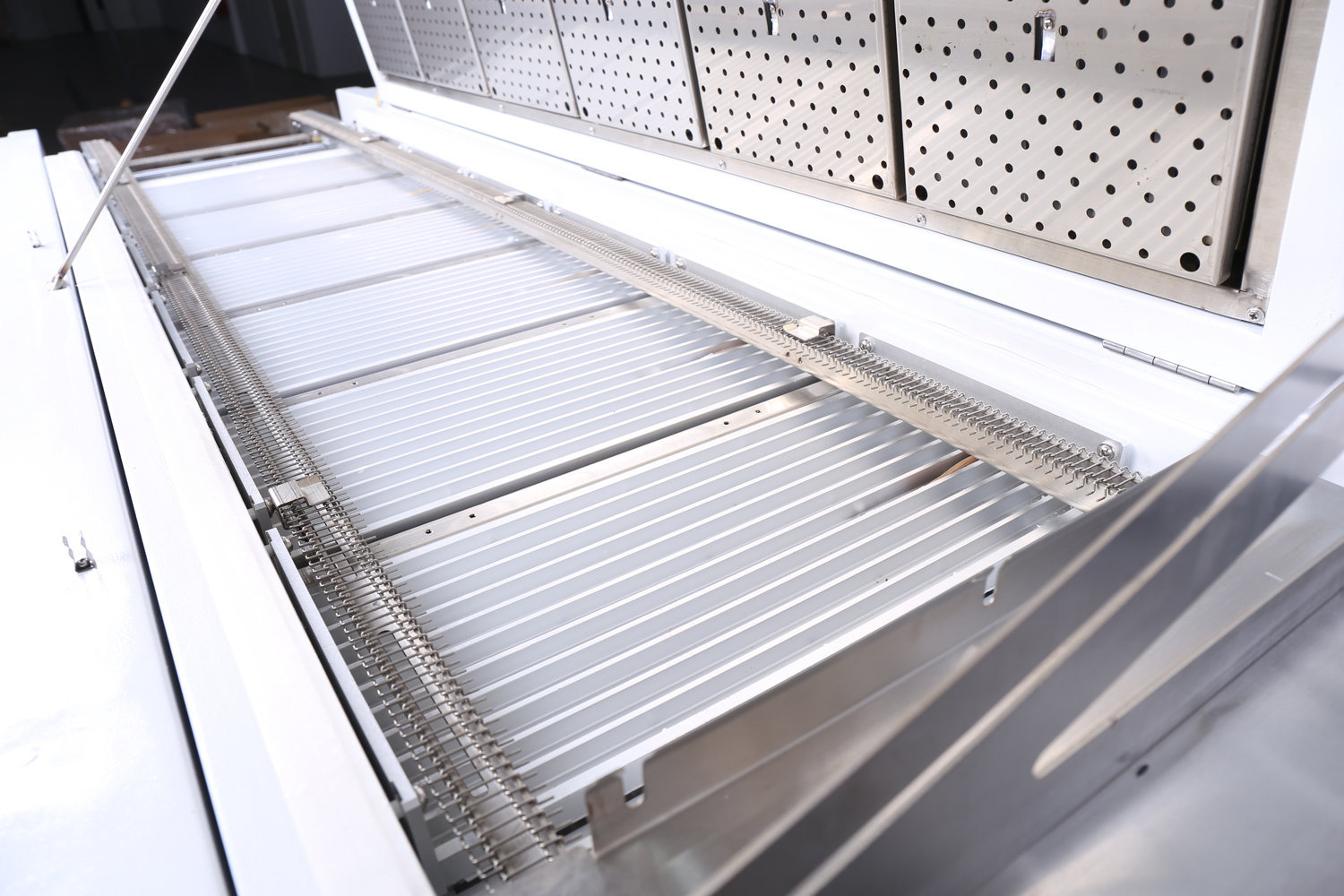

12 Heating Zones

Uniform temperature

High temperature control accuracy

Cooling zone

Independent circulating air design

Isolates the influence of the external environment

Energy saving & Eco-friendly

Welding smoke filtering system

low power and supply requirements

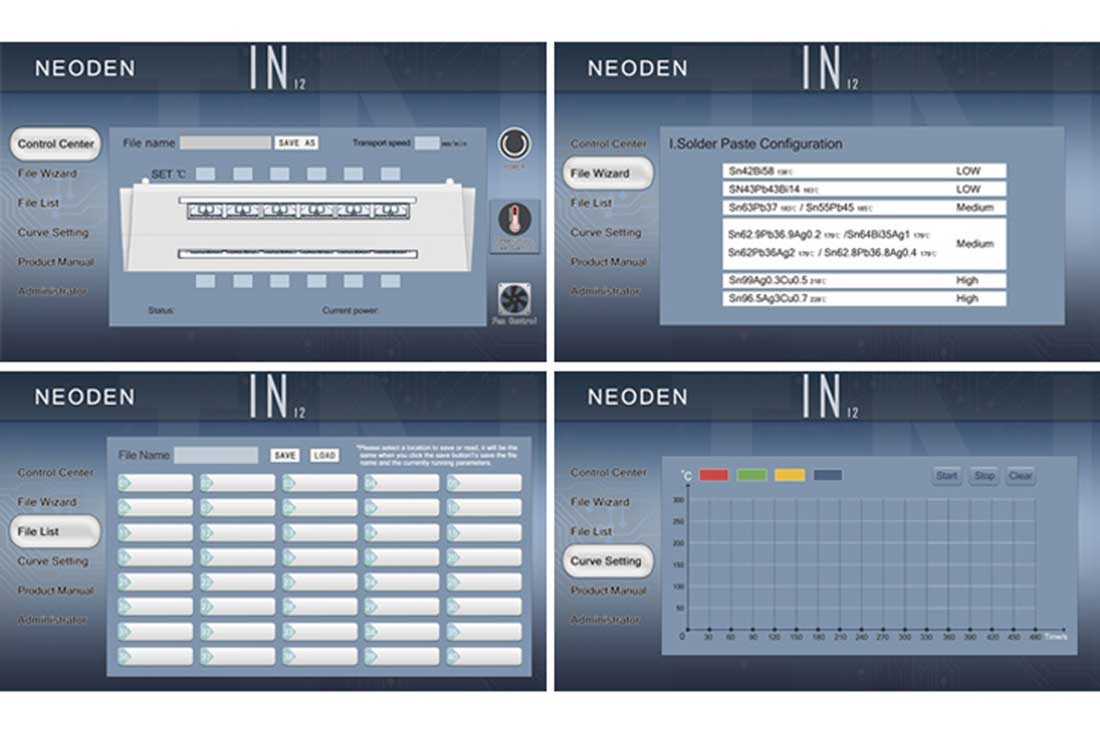

Operation panel

Hidden screen design

Convenient for transportation

Intelligent control system

Custom developed intelligent control system

Temperature curve can be displayed

Elegant appearance

In line with high-end use environment

Lightweight, miniaturization, professional

Features

1. Unique heating module design, with high precision temperature control, uniform temperature distribution in the thermal compensation area, high efficiency of thermal compensation, low power consumption and other characteristics.

2. Can store 40 working files.

3. Up to 4-way real-time display of PCB board surface welding temperature curve.

4. Custom-developed track drive motor according to the characteristics of the B-type mesh belt, to ensure uniform speed and long life.

5. High-precision profile process to complete the mesh chain wheel, with a unique support structure can effectively reduce the vibration of the PCB board in the reflow area, easily cope with the welding of small devices of the 0201 class and BGA class complex chips.

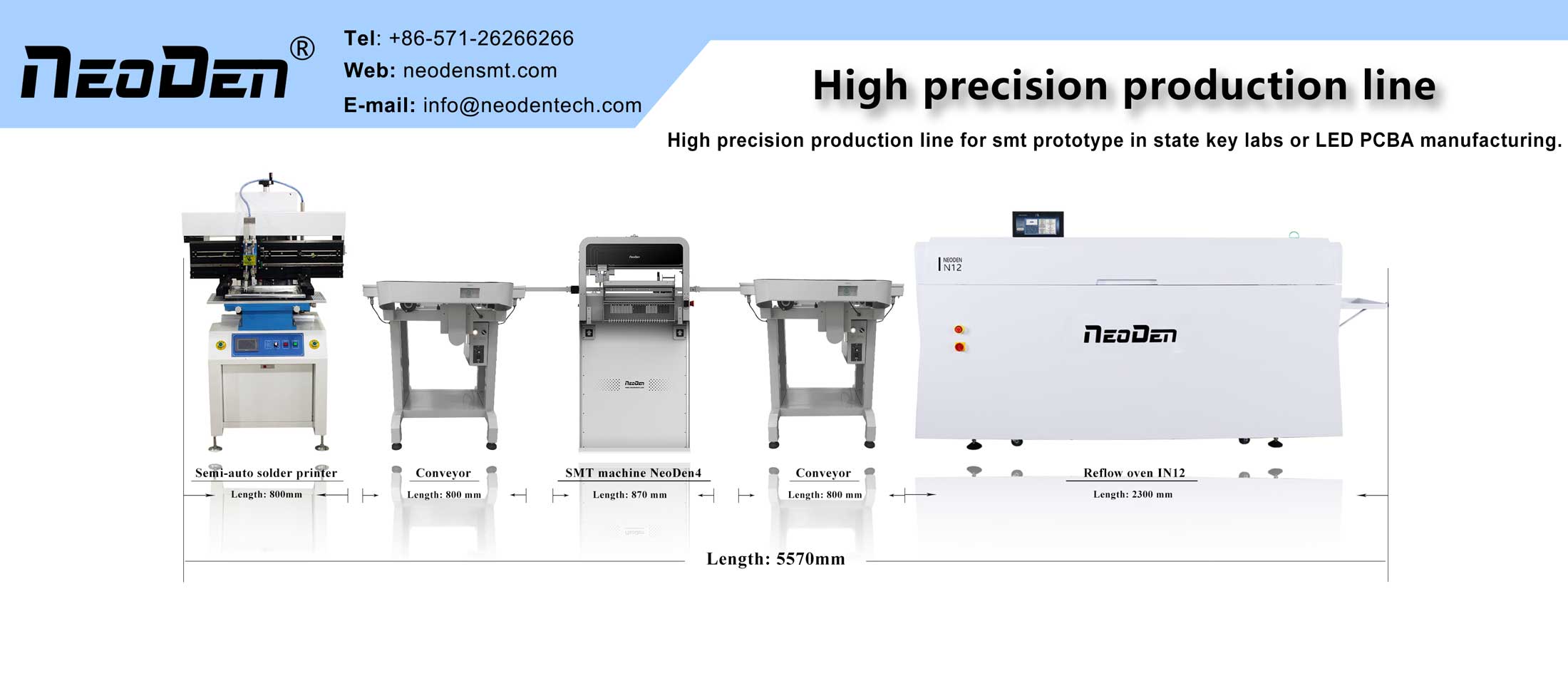

Provide one-stop SMT assembly production line

Related products

FAQ

Q1: What about the lead time for mass production?

A: Honestly, it depends on the order quantity and the season you place the order.

Alway 15-30 days based on general order.

Q2: Can I request to change the form of packaging and transportation?

A: Yes, we can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

Q3: Visting factory is allowed or not?

A: Yes, we welcome customers visiting our factory.

Our factory is located Huzhou city, Zhejiang province, China mainland.

About us

Factory

Exhibition

Certification

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.