NeoDen IN12C PCB Soldering Reflow Oven

NeoDen IN12C PCB Soldering Reflow Oven

Specification

| Product name | NeoDen IN12C PCB Soldering Reflow Oven |

| Model | NeoDen IN12C |

| Heating Zone Quantity | Upper6 / Down6 |

| Cooling Fan | Upper4 |

| Conveyor Speed | 50~600 mm/min |

| Temperature Range | Room temperature~300℃ |

| Temperature Accuracy | 1℃ |

| PCB Temperature Deviation | ±2℃ |

| Max soldering height(mm) | 35mm (includes PCB thickness) |

| Max Soldering Width (PCB Width) | 350mm |

| Length Process Chamber | 1354mm |

| Electricity Supply | AC 220v/single phase |

| Machine Size | L2305mm×W612mm×H1230mm |

| Heat-up Time | 30 min |

| Net Weight | 300Kgs |

Details

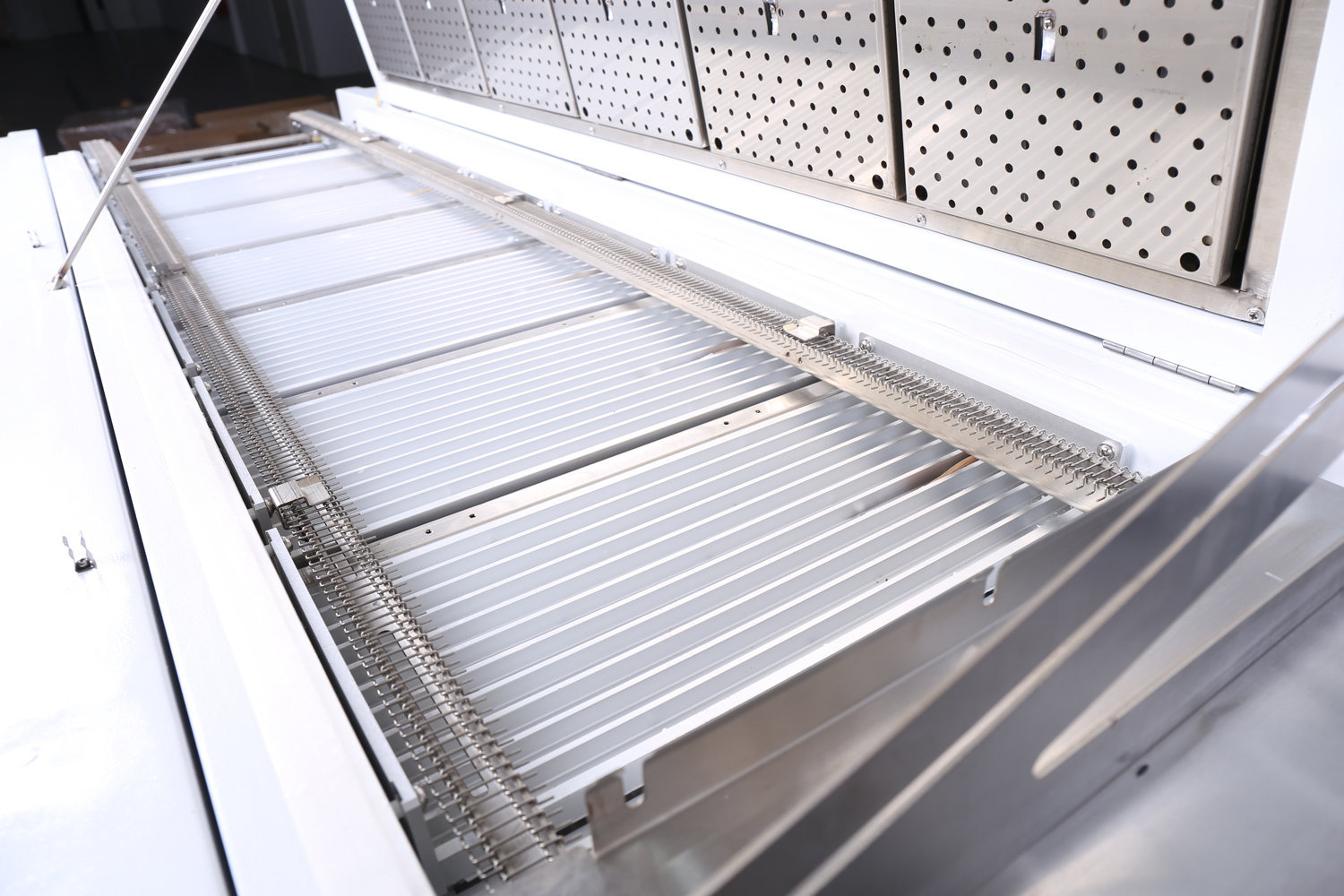

12 Heating Zones

Uniform temperature

High temperature control accuracy

Cooling zone

Independent circulating air design

Isolates the influence of the external environment

Energy saving & Eco-friendly

Welding smoke filtering system

low power and supply requirements

Operation panel

Hidden screen design

Convenient for transportation

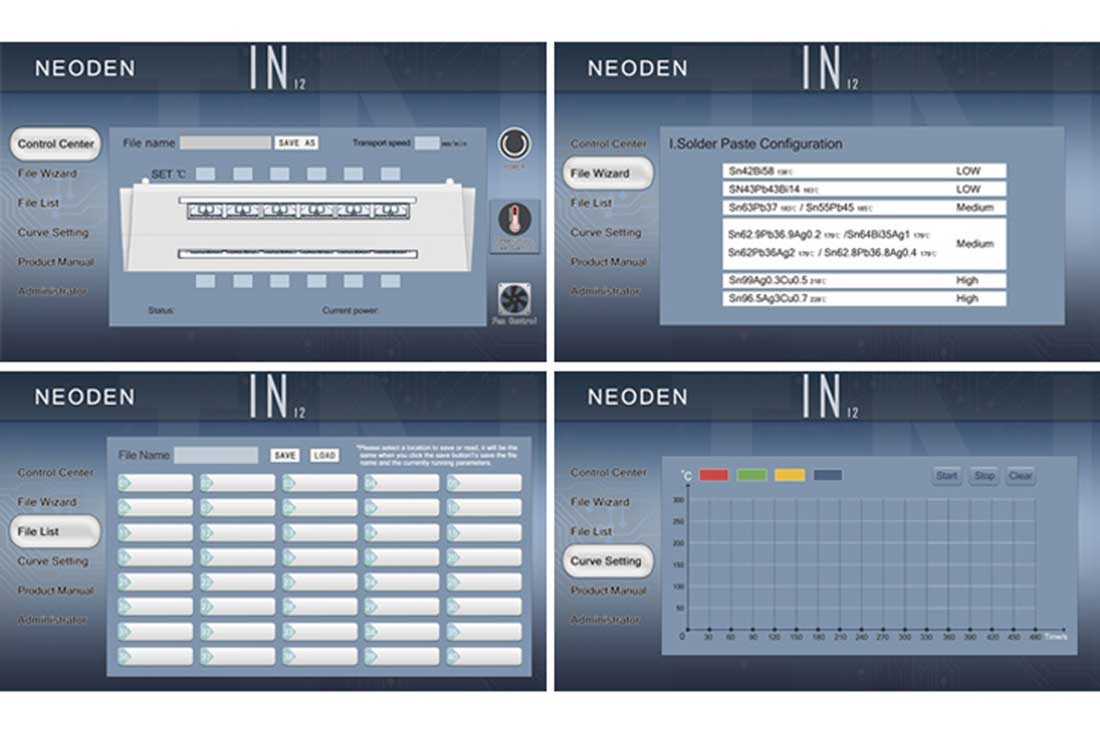

Intelligent control system

Custom developed intelligent control system

Temperature curve can be displayed

Elegant appearance

In line with high-end use environment

Lightweight, miniaturization, professional

Features

1. The control system has the characteristics of high integration, timely response, low failure rate, easy maintenance, etc.

2. The use of high-performance aluminum alloy heating plate instead of heating tube, both energy-saving and efficient, compared with similar reflow ovens on the market, the lateral temperature deviation is significantly reduced.

3. lightweight, miniaturization, professional industrial design, flexible application scenarios, more humane.

4. through the special airflow simulation software test optimized welding fume filtration system, can achieve the filtration of harmful gases at the same time to ensure that the equipment shell to maintain room temperature, reduce heat loss and reduce power consumption.

5. Unique heating plate design effectively ensures uniform cooling after the equipment stops heating, effectively preventing the parts from being damaged by the rapid decrease in temperature and the resulting deformation.

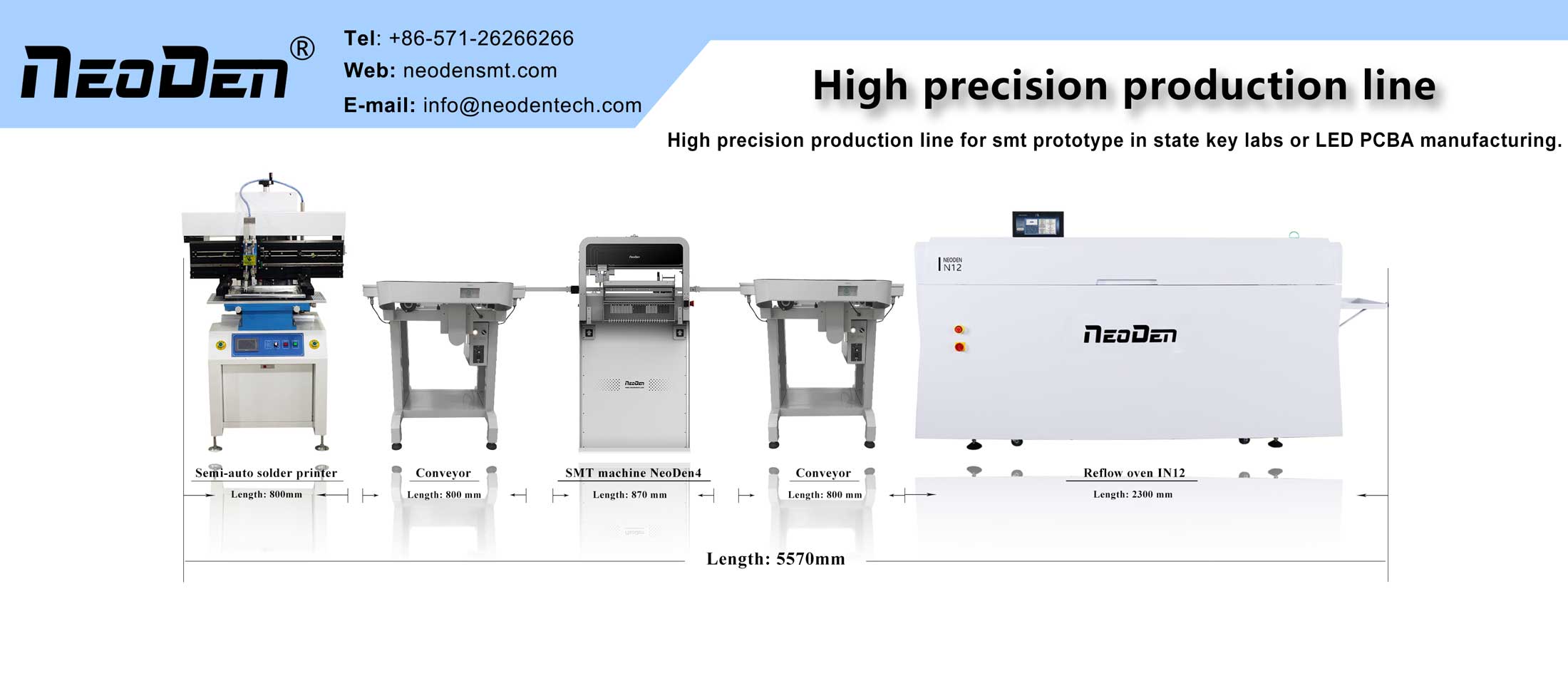

Provide one-stop SMT assembly production line

Related products

FAQ

Q1: This is the first time I use this kind of machine, is it easy to operate ?

A: We have English user manual and guide video to teach you how to use the machine.

If still have question, pls contact us by email / skype / whatapp / phone / trademanager online service.

Q2: What's the way of shipping?

A: These are all heavy machines; we suggest you use cargo ship. But components for mending the machines, air transportation would be fine.

Q3: How do I pay?

A: My friend, there are many ways.

T/T(we prefer this one), Western Union, PayPal, choose your favorite one.

Q4: How about the warranty?

A: We support one year warranty.

We will help you in time.

All the spare parts will be provided free of charge for you within the warranty period.

About us

Factory

Exhibition

Certification

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.