NeoDen IN12 SMD Reflow Oven

NeoDen IN12 SMD Reflow Oven

Specification

1. Hot air convection, excellent soldering performance.

2. High-performance aluminum alloy heating plate instead of heating pipe, both energy-saving and high-efficient, and transverse temperature deviation is significantly reduced compare to the similar reflow oven products in the market.

3. The cooling zone with independent circulating air design completely isolates the influence of the external environment on the internal temperature chambers.

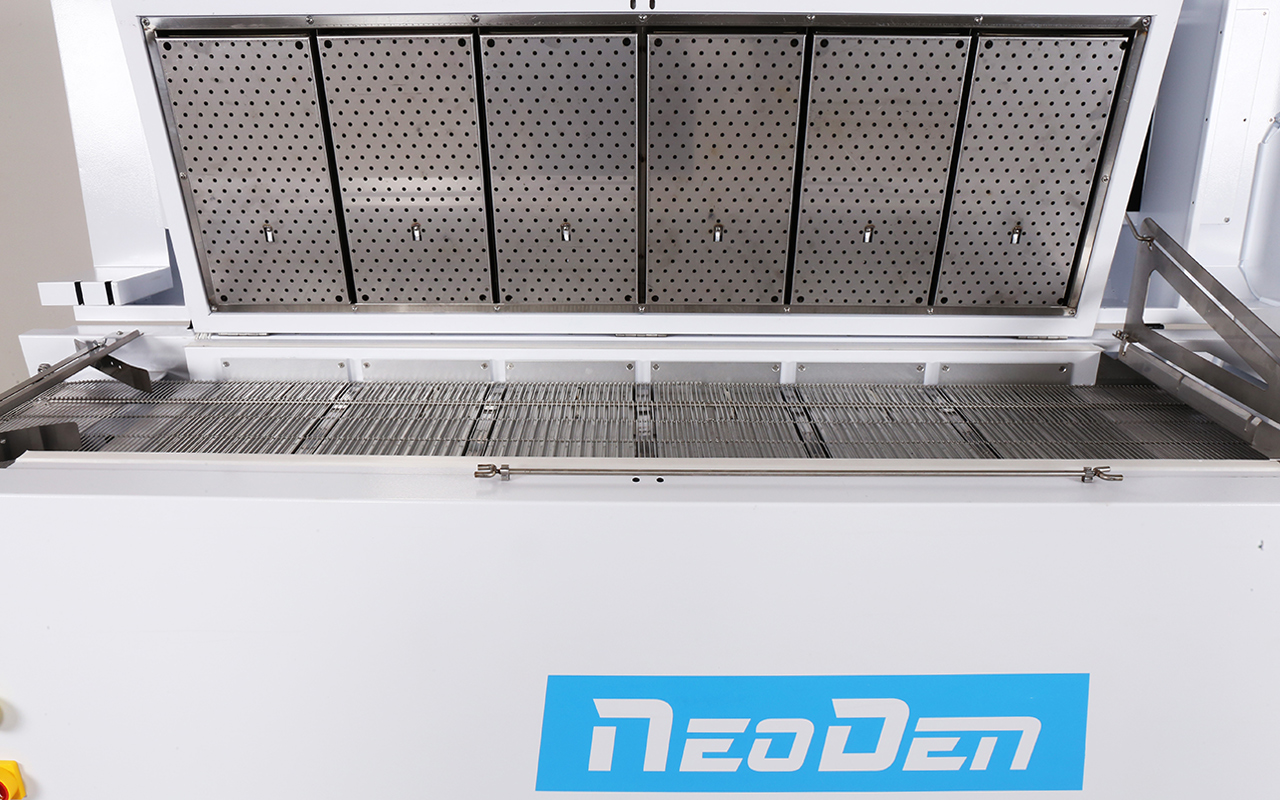

4. Exclusively designed PCB guide device to realize the direct connection between the mesh chain and the conveyor.

Feature

Product name: NeoDen IN12 SMD Reflow Oven

Cooling fan: Upper4

Conveyor speed: 50~600 mm/min

Temperature range: Room temperature~300℃

PCB temperature deviation: ±2℃

Max soldering height(mm): 35mm (includes PCB thickness)

Max soldering width (PCB Width): 350mm

Length process chamber: 1354mm

Electricity supply: AC 220v/single phase

Machine size: L2300mm×W650mm×H1280mm

Heat-up time: 30 min

Net weight: 300Kgs

Details

12 temperature zones

High temperature control accuracy

Uniform temperature distribution in the thermal compensation area

Cooling zone

Independent circulating air design

Isolates the influence of the external environment

Energy saving & Eco-friendly

Welding smoke filtering system

low power consumption, low power supply requirements

Operation panel

Hidden screen design

convenient for transportation

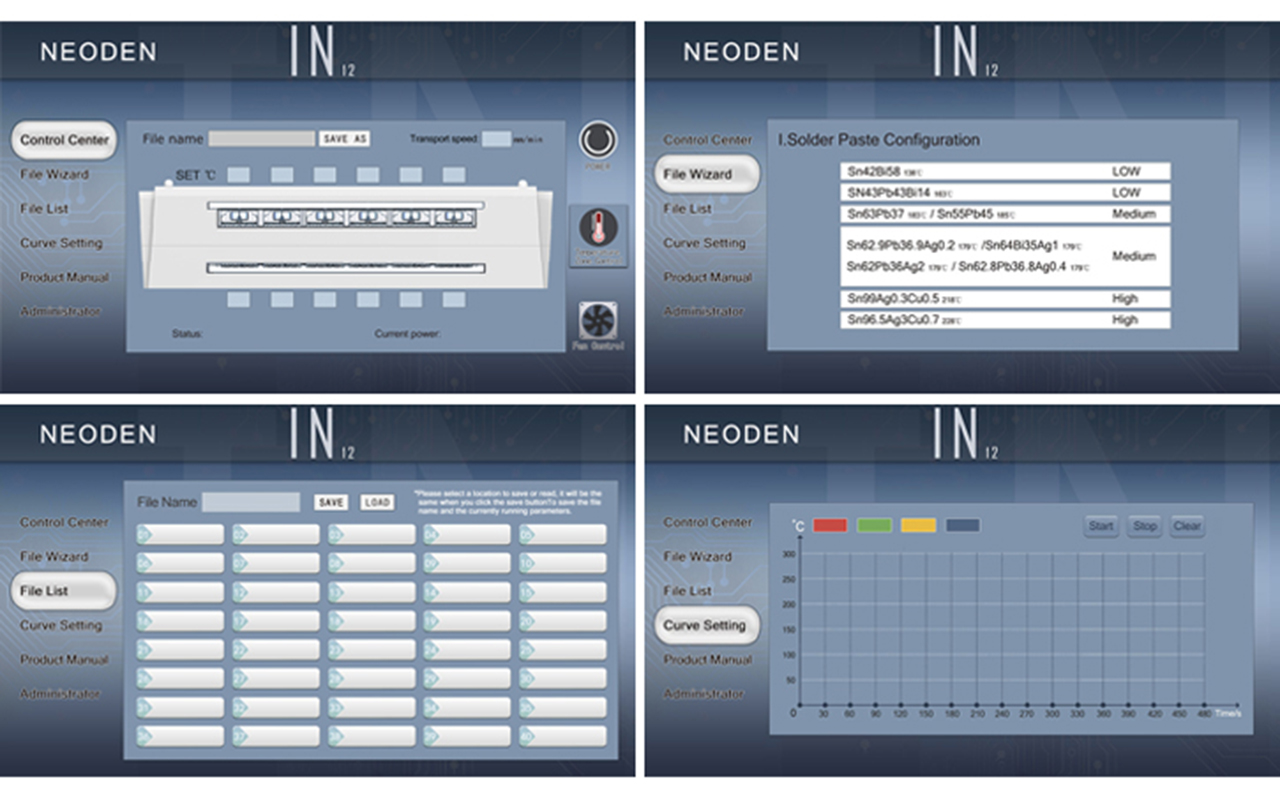

Intelligent control system

Custom developed intelligent control system

Temperature curve can be displayed

Elegant appearance

In line with high-end use environment

Lightweight, miniaturization, professional

What is PCB surface temperature?

The temperature of component soldering feet when PCB is soldered.

(the guide temperature on the soldering wave provided by the solder paste manufacturer refers to the PCB surface temperature.)

When working, the temperature displayed in the temperature zone on the panel is the actual temperature of the heating unit, which does not represent the temperature in the oven and the actual temperature of the plate surface.

Therefore, the temperature displayed will be about 20-40 degrees higher than the temperature in the oven. The actual use is related to the chain speed, PCB size, thickness, material and component density.

FAQ

Q1: What’s your tem of the delivery?

A: Our ordinary delivery term is FOB Shanghai.

We also accept EXW, CFR, CIF, DDP, DDU etc.

We’ll offer you the shipping charges and you can choose the one which is the most convenient and effective for you.

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry.

If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Is there the products tested before shipping?

A: Yes, of course.

All of our conveyor belt we all will has been 100% QC before shipping. We test every batch every day.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.