NeoDen IN12 Reflow Oven for PCB Welding

NeoDen IN12 Reflow Oven for PCB Welding

Product Overview

Brand

Country/Region of Manufacture

Heating zone quality

Conveyor speed

Max Height

NeoDen

China

Upper6/Down6

50-600mm/min

35mm

Model

Application

Soldering width

Dimensions

N.W.

NeoDen IN12

SMT equipment, PCB soldering

350mm

2300*650*1280mm

300Kg

Description

1. Built-in welding smoke filtering system, effective filtration of harmful gases, elegant appearance and eco-friendly, more in line with the high-end use environment.

2. The unique design of heating module has the characteristics of high temperature control accuracy, uniform temperature distribution in the thermal compensation area, high thermal compensation efficiency and low power consumption.

3. 40 working files can be stored for an easy loading during the working process.

4. Professional and unique 4-way board surface temperature monitoring system, can give timely and comprehensive data feedback in actual operation, which can effectively cope with any complex electronic products.

5. The mesh sprocket made of high-precision profile technology and the unique support structure can effectively reduce the vibration of the PCB in the reflow zones, and easily cope with the welding of small size components such as 0201 and complex chips such as BGA/QFP/QFN.

Details

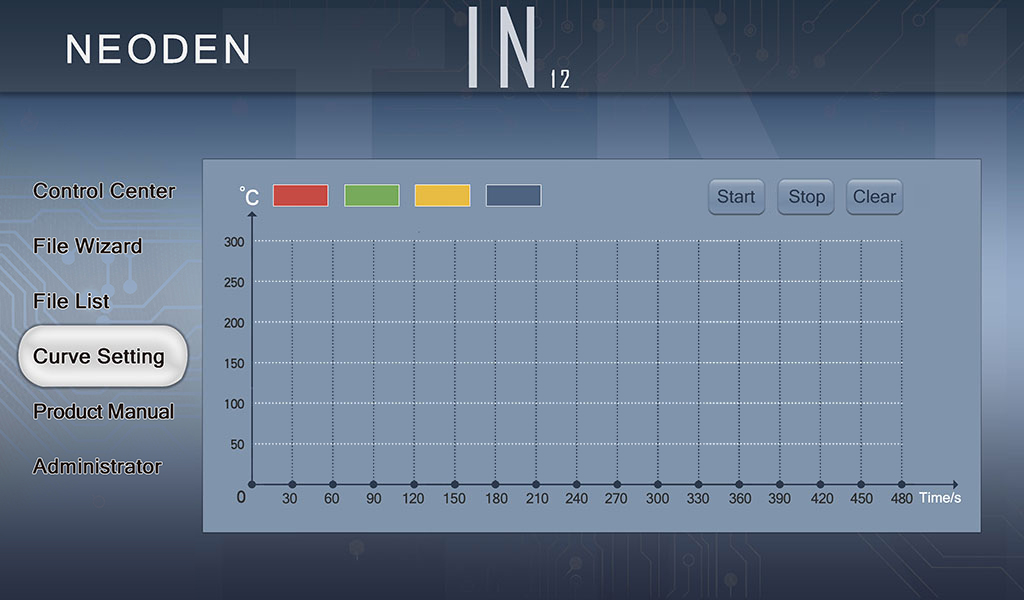

Real-time measurement

1- PCB soldering temperature curve can be displayed based on real-time measurement.

2- Professional and unique 4-way board surface temperature monitoring system, can give timely and comprehensive data feedback in actual operation.

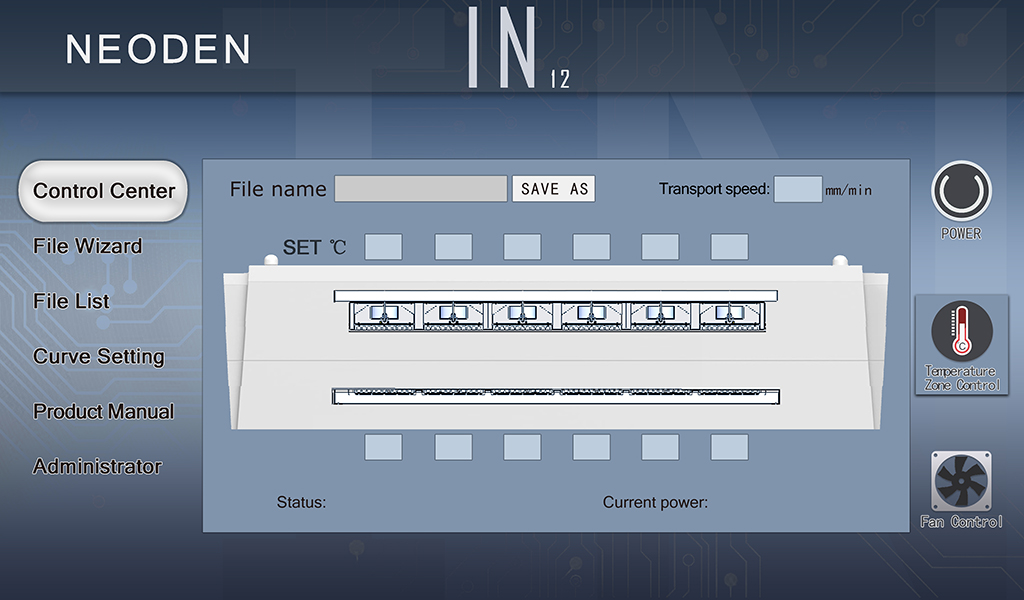

Intelligent control system

1-Heat insulation protection design, the casing temperature can be effectively controlled.

2- Smart control with high sensitivity temperature sensor, the temperature can be effectively stabilized.

3-Intelligent, the custom developed intelligent control system, easy to use and powerful.

Energy saving & Eco-friendly

1-Built-in welding smoke filtering system, effective filtration of harmful gases.

2-Energy saving, low power consumption, low power supply requirements, the ordinary civil electricity can meet the use.

3-The internal thermostat is made of stainless steel, which is environment friendly and has no peculiar smell.

Attentive design

1-Hidden screen design is convenient for transportation, easy to use.

2-The upper temperature cover is automatically limited once opened, effectively ensuring the personal safety for the operators.

Specification

| Product name | NeoDen IN12 reflow oven for PCB welding |

| Model | NeoDen IN12 |

| Heating Zone Quantity | Upper6 / Down6 |

| Cooling Fan | Upper4 |

| Conveyor Speed | 50~600 mm/min |

| Temperature Range | Room temperature~300℃ |

| Temperature Accuracy | 1℃ |

| PCB Temperature Deviation | ±2℃ |

| Max soldering height | 35mm (includes PCB thickness) |

| Max Soldering Width (PCB Width) | 350mm |

| Length Process Chamber | 1354mm |

| Electricity Supply | AC 220v/single phase |

| Machine Size | L2300mm×W650mm×H1280mm |

| Heat-up Time | 30 min |

| Net Weight | 300Kgs |

Our Service

We are in a good position not only to supply you high quality pnp machine, but also the excellent after sales service.

Well-trained engineers will offer you any technical support.

10 engineers powerful after-sales service team can respond customers queries and enquiries within 8 hours.

Professional solutions can be offered within 24 hours both workday and holidays.

About us

Factory

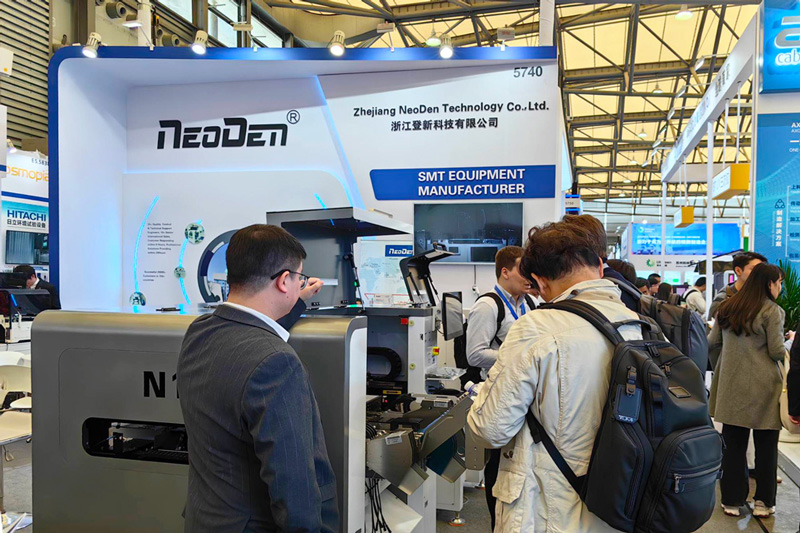

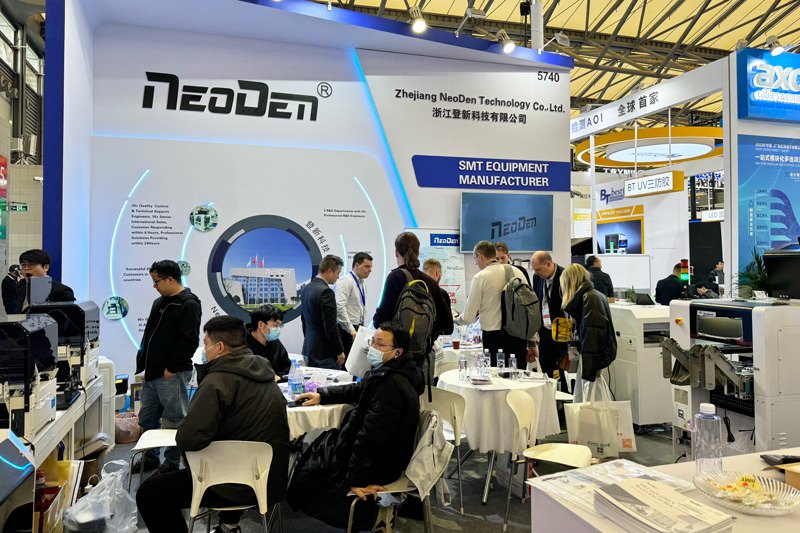

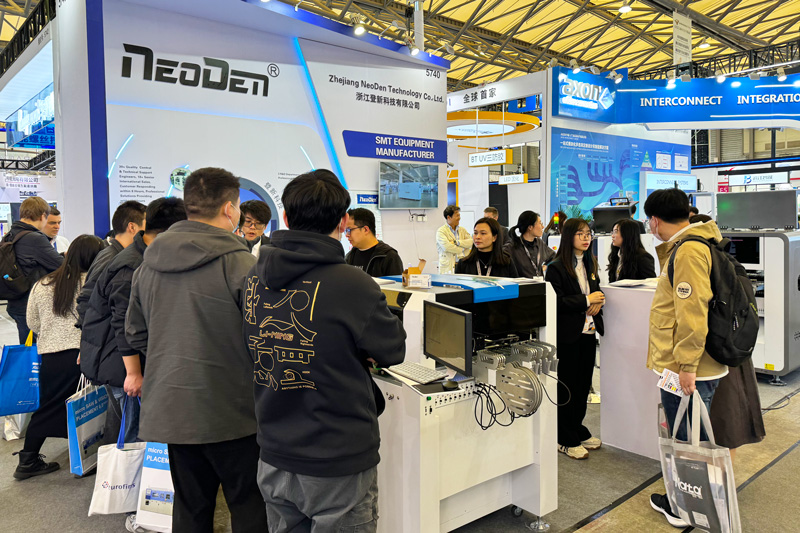

Exhibition

Certification

FAQ

Q1. What is your advantage compared with your competitors?

A. (1). Qualified Manufacturer

(2). Reliable Quality Control

(3). Competitive Price

(4). High Efficiency working (24*7hours)

(5). One-Stop Service

Q2. Is it hard to use NeoDen IN12 SMT reflow oven?

A. No, not hard at all.

There are English manual and guide video that show you how to use NeoDen IN12.

If there is any doubt in the process of operating the reflow oven, please feel free contact us.

We also provide overseas on-site service and life time after-sales online support.

Q3. Is there the NeoDen IN12 reflow machine tested before shipping?

A. Yes, of course.

All of our reflow machine have been 100% QC before shipping.

We test every batch every day and will be responsible for any quality problem.

Q4. What we can do for you?

A. Total SMT reflow oven and SMT solution, professional technical support and service.

Q5. What about the after-sale service?

A. We provide 24 months quality warranty, and we also provide long time free technical advisory services.

We will dispatch our engineer to go aboard to provide technical service if it is necessary.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.