NeoDen IN12 PCB Soldering Reflow Oven

NeoDen IN12 PCB Soldering Reflow Oven

Specification

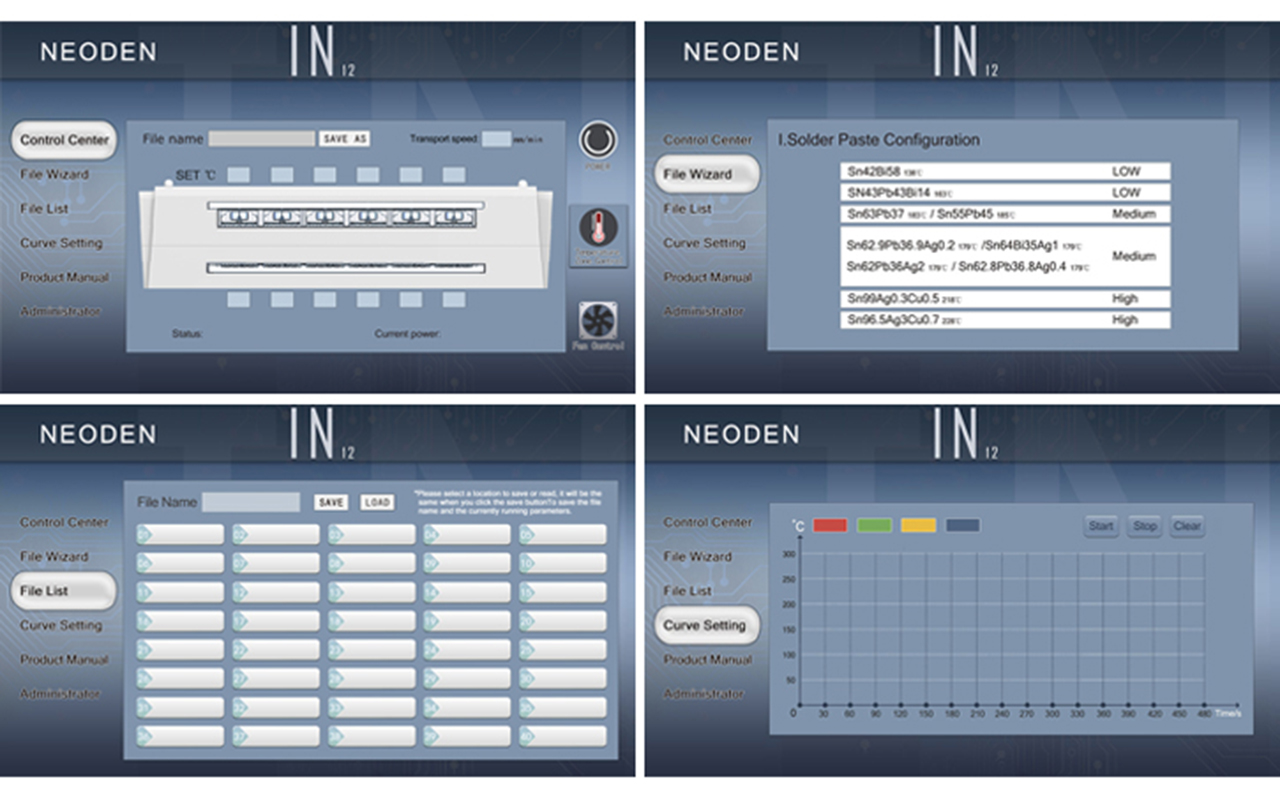

1. The control system has features of high integration, timely response, low failure rate and convenient maintenance.

2. Professional and unique 4-way board surface temperature monitoring system, can give timely and comprehensive data feedback in actual operation, which can effectively cope with any complex electronic products.

3. Lightweight, miniaturization, professional industrial design, flexible application site, more user-friendly.

4. The control system adopts imported chips, and the temperature control accuracy reaches ±0.5%.

Feature

Product name: NeoDen IN12 PCB Soldering Reflow Oven

Cooling fan: Upper4

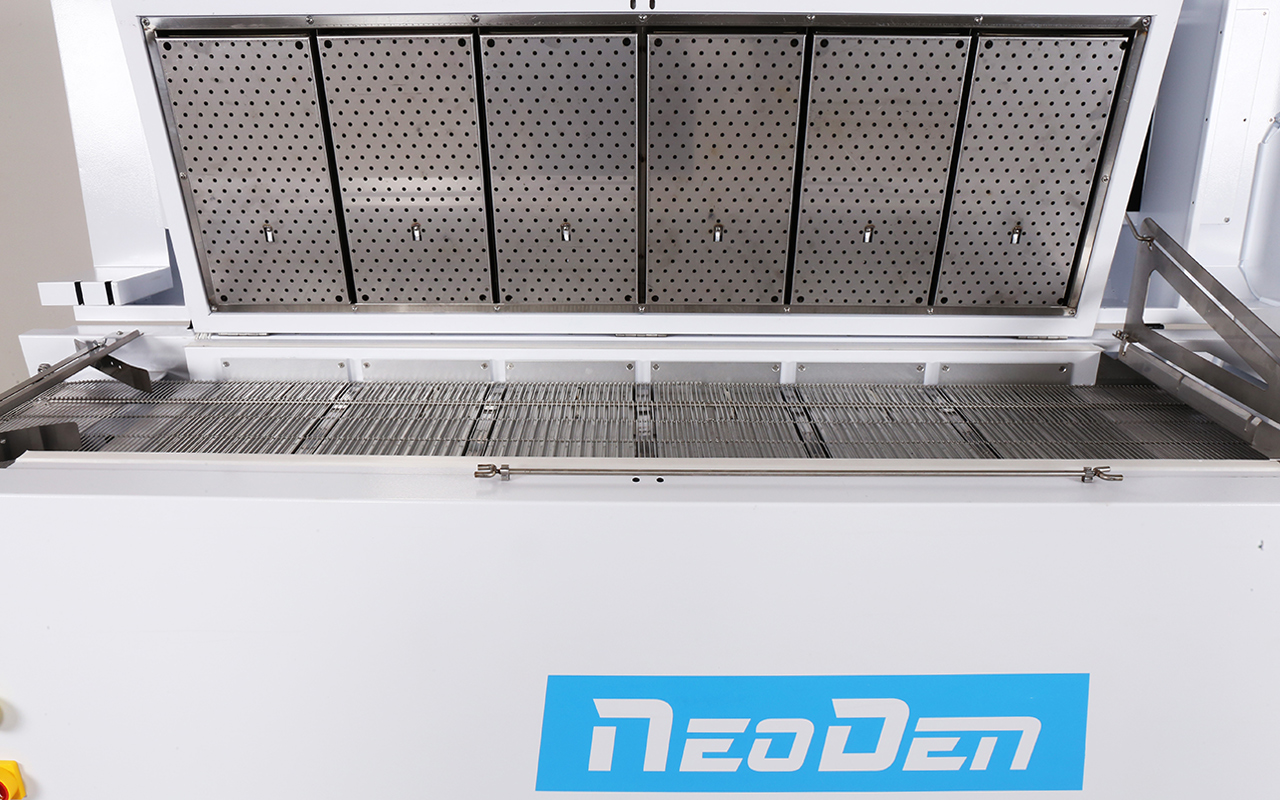

Conveyor speed: 50~600 mm/min

Temperature range: Room temperature~300℃

PCB temperature deviation: ±2℃

Max soldering height(mm): 35mm (includes PCB thickness)

Max soldering width (PCB Width): 350mm

Length process chamber: 1354mm

Electricity supply: AC 220v/single phase

Machine size: L2300mm×W650mm×H1280mm

Heat-up time: 30 min

Net weight: 300Kgs

Details

12 temperature zones

High temperature control accuracy

Uniform temperature distribution in the thermal compensation area

Cooling zone

Independent circulating air design

Isolates the influence of the external environment

Energy saving & Eco-friendly

Welding smoke filtering system

low power consumption, low power supply requirements

Operation panel

Hidden screen design

convenient for transportation

Intelligent control system

Custom developed intelligent control system

Temperature curve can be displayed

Elegant appearance

In line with high-end use environment

Lightweight, miniaturization, professional

What is PCB surface temperature?

The temperature of component soldering feet when PCB is soldered.

(the guide temperature on the soldering wave provided by the solder paste manufacturer refers to the PCB surface temperature.)

When working, the temperature displayed in the temperature zone on the panel is the actual temperature of the heating unit, which does not represent the temperature in the oven and the actual temperature of the plate surface.

Therefore, the temperature displayed will be about 20-40 degrees higher than the temperature in the oven. The actual use is related to the chain speed, PCB size, thickness, material and component density.

Our Services

1. Good knowledge on different market can meet special requirements.

2. Real manufacturer with our own factory located in Huzhou, China.

3. Strong professional technical team ensure to produce the top quality products.

4. Special cost control system ensure to provide the most favorable price.

5. Rich experience on SMT area.

FAQ

Q1: What's the way of shipping?

A: These are all heavy machines; we suggest you use cargo ship.

But components for mending the machines, air transportation would be fine.

Q2: How do I pay?

A: My friend, there are many ways.

T/T(we prefer this one), Western Union, PayPal, choose your favorite one.

Q3: What’s is your shipping service?

A: We can provide services for vessel booking, goods consolidation, customs declaration, shipping documents preparation and delivery bulk at the shipping port.

About us

Factory

Owned the own machining center, skilled assembler, tester and QC engineers, to ensure the strong abilities for NeoDen machines manufacturing, quality and delivery.

3 different R&D teams with total 25+ professional R&D engineers, to ensure the better and more advanced developments and new innovation.

The unique one among all of the Chinese manufacturers who registered and approved CE by TUV NORD.

Exhibition

Certification

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.