NeoDen Benchtop Pick and Place Machine

NeoDen Benchtop Pick and Place Machine

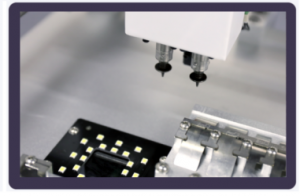

NeoDen 3V

Benchtop Pick and Place Machine

2 Heads, ±180° rotation head system

Small volume, low power

High speed and accuracy

Stable performance and easy operation

Specification

| Product Name | NeoDen Benchtop Pick and Place Machine |

||

| Machine Style | Single Gantry with 2 heads | Model | NeoDen 3V-Advanced |

| Placement Rate | 3,500CPH Vision on/5,000CPH Vision off | Placement Accuracy | +/-0.05mm |

| Feeder Capacity | Max Tape Feeder: 44pcs (All 8mm width) | Alignment | Stage Vision |

| Vibration Feeder: 5 | Component Range | Smallest Size: 0402 | |

| Tray Feeder: 10 | Biggest Size: TQFP144 | ||

| Rotation | +/-180° | Max Height: 5mm | |

| Electricity Supply | 110V/220V | Max Board Dimension | 320x390mm |

| Power | 160~200W | Machine Size | L820×W680×H410mm |

| Net Weight | 60Kg | Packing Size | L1010×W790×H580 mm |

Detail

2 heads

Full Vision 2 heads system

±180° rotation satisfy the need of wide range components

Patented Automatic Peel-box

Feeder Capacity: 44*Tape feeder(all 8mm),

5*Vibration feeder, 10* IC Tray feeder

Flexible PCB positioning

Using PCB support bars and pins,

wherever to put the PCB, whatever the shape of PCB.

Integrated Controller

More stable performance and easier to do maintenance.

NeoDen FP2636

1. Straight damping shaft,ensure the stencil fixed frame can be fastened at random angles,to improve convenience while operating.

2. The mechanical fixation frame for quick installation and replacement of frameless stencils,ensure high-efficiency but low-cost.

NeoDen IN6

1. Original high-performance aluminum alloy heating plate instead of heating pipe, both energy-saving and high-efficient, and transverse temperature difference is less than 2℃.

2. An internal temperature sensor ensures full control of the heating chamber and can reach optimal temperatures in as little as fifteen minutes.

Click on the picture below to jump to the appropriate product:

About us

About us

Certification

Exhibition

FAQ

Q1: What’s is your shipping service?

A: We can provide services for vessel booking, goods consolidation, customs declaration, shipping documents preparation and delivery bulk at the shipping port.

Q2: What's your products?

A. SMT machine, AOI, reflow oven, PCB loader, stencil printer.

Q3: Is there the products tested before shipping?

A: Yes, of course. All of our conveyor belt we all will has been 100% QC before shipping. We test every batch every day.

If you need, please feel free to contact us for more information!

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.