NeoDen Automatic PCB Stencil Printer

NeoDen Automatic PCB Stencil Printer

Specification

| Product name | NeoDen Automatic PCB Stencil Printer |

| Maximum board size(X x Y) | 450mm x 350mm |

| Minimum board size(X x Y) | 50mm x 50mm |

| PCB thickness | 0.4mm~6mm |

| Warpage | ≤1% Diagonal |

| Maximum board weight | 3Kg |

| Board margin gap | Configuration to 3mm |

| Maximum bottom gap | 20mm |

| Transfer speed | 1500mm/s(Max) |

| Transfer height from the ground | 900±40mm |

| Transfer orbit direction | L-R,R-L,L-L,R-R |

| Machine weight | Appro.1000Kg |

Feature

Standard Configuration

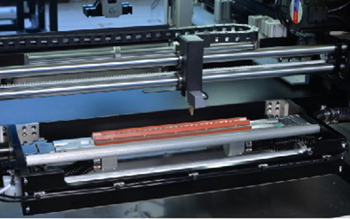

1. Intelligent squeegee system

Intelligent programmable setting, two independent direct motors driven squeegee, built-in precise pressure control system.

2. High efficiency and high adaptability stencil cleaning system

The new wiping system ensures full contact with the stencil.

Three cleaning methods of dry, wet and vacuum, and free combination can be selected.

Soft wear-resistant rubber wiping plate, thorough cleaning, convenient disassembly, and universal length of wiping paper.

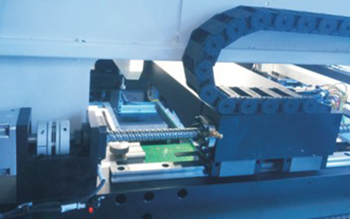

3. Printing axis servo drive

The scraper Y axis adopts servo motor drive through screw drive,to improve accuracy grade, operational stability and extend the service life, to provide customers with a good printing control platform.

Options Configuration

1. Automatic Solder Paste filling function

Automatically add solder paste at fixed time and fixed point to ensure the quality of solder paste and the amount of solder paste in the steel mesh.

In order to ensure that customers can carry out quality stability and long-term continuous printing, improve productivity.

2. Detection function on Stencil

By compensating the light source above the steel stencil, CCD is used to check the mesh in real time, so as to quickly detect and judge whether the mesh is blocked after cleaning, and carry out automatic cleaning, which is a supplement to the 2D detection of PCB.

Quality control

We have QC person stay on the production lines do to the inspection.

All products must have been inspected before delivery.

We do inline inspection and final inspection.

1. All raw material checked once it arrive our factory.

2. All pieces and logo and all details checked during production.

3. All packing details checked during production.

4. All production quality and packing checked on final inspection after finished.

Provide one-stop SMT assembly production line

Related products

About us

Factory

Established in 2010 with 100+ employees & 8000+ Sq.m. factory of independent property rights, to ensure the standard management and achieve the most economic effects as well as saving the cost.

Owned the own machining center,skilled assembler,tester and QC engineers,to ensure the strong abilities for NeoDen machines manufacturing,quality and delivery.

40+ global partners covered in Asia,Europe,America,Oceania and Africa,to successfully serve 10000+ users in all of the world,to ensure the better and faster local service and prompt response.

The unique one among all of the Chinese manufacturers who registered and approved CE by TUV NORD.

Certification

Exhibition

FAQ

Q1: What’s your tem of the delivery?

A: Our ordinary delivery term is FOB Shanghai.

We also accept EXW, CFR, CIF, DDP, DDU etc.

We’ll offer you the shipping charges and you can choose the one which is the most convenient and effective for you.

Q2: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3: Have your products been exported?

A: Yes, they have been exported to USA, Canada, Australia, Russia, Chile, Panama, Nicaragua, UAE, Saudi Arabia, Egypt, Sri Lanka, Nigeria, Iran, Vietnam, Indonisia, Singapore, Greece, Netherland, Georgia, Romania, Ireland, India, Thailand, Pakistan, Philippines, Singapore, HK, Taiwan...

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.