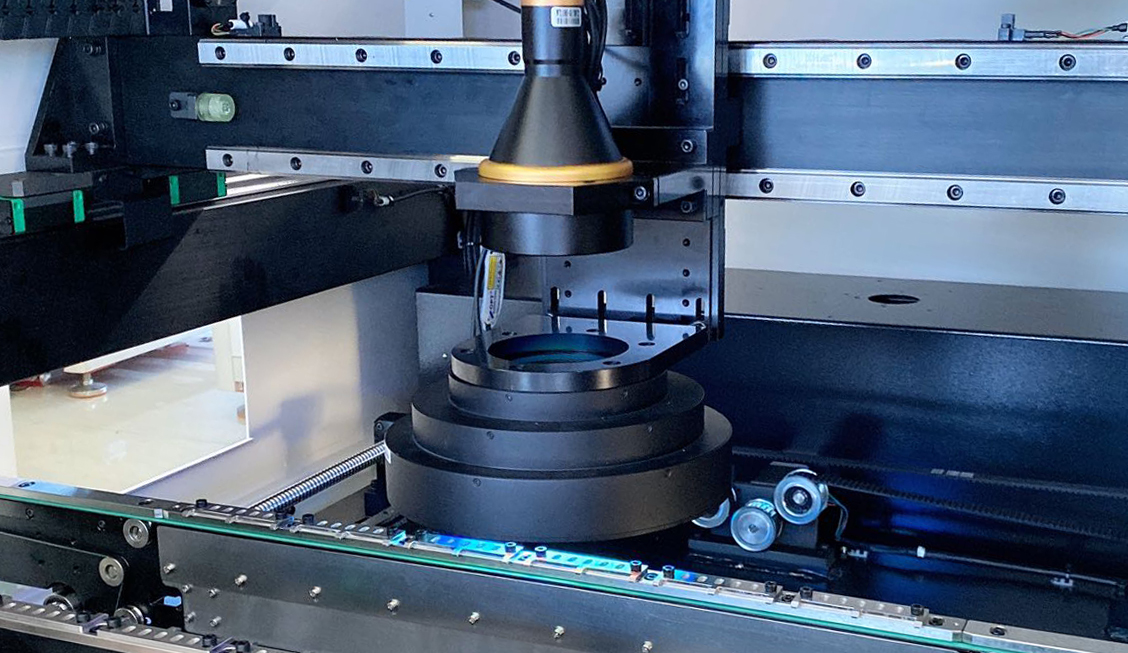

NeoDen AOI Soldering Testing Machine

NeoDen AOI Soldering Testing Machine

Machine characteristic

HD color global exposure digital camera speed increase 30%

High depth of field telecentric lens, which can measure the solder joints on the side of high components

Support the detection of smt front, back and dip station

MES data docking to realize intelligent factory

Support multi-line centralized management and remote service

Specification

| Product name | NeoDen AOI Soldering Testing Machine |

| Model | ALE |

| PCB Thickness | 0.6mm~6mm |

| Max. PCB Size (X x Y) | 510mm x 460mm |

| Min. PCB Size (Y x X) | 50mm x 50mm |

| Max. Bottom Gap | 50mm |

| Max. Top Gap | 35mm |

| Moving speed | 1500mm/Sec(Max) |

| Transmission height from the ground | 900±30mm |

| Transmission Method | One Stage Lane |

| PCB clamping method | Edge locking substrate clamping |

| Weight | 750KG |

Features

Image Parameters

Camera: GigE Vision(Gigabit network interface)

Resolution: 2448*2048(500 Mega Pixels)

FOV: 36mm*30mm

Resolution: 15μm

Lighting System: Multi-angle surrounding LED light source

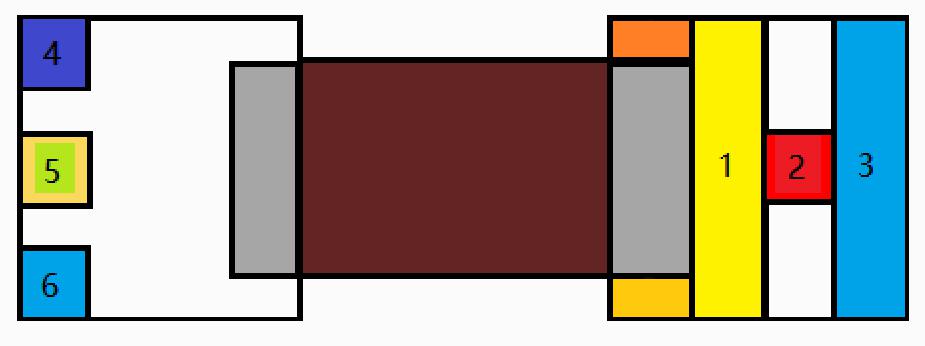

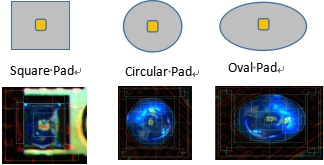

Compreshensive Pad Defect Detection

Divide the pad into multiple areas, each area has the characteristics of good and bad products, set the corresponding detection standards to measure.

Compatible with Various Shapes of Pads

Wave soldering algorithm supports various shapes of pads, positioning is more accurate.

Quality control

We have QC person stay on the production lines do to the inspection.

All products must have been inspected before delivery. We do inline inspection and final inspection.

1. All raw material checked once it arrive our factory.

2. All pieces and logo and all details checked during production.

3. All packing details checked during production.

4. All production quality and packing checked on final inspection after finished.

Provide one-stop SMT assembly production line

About us

Our Factory

Quick facts about NeoDen

① Established in 2010, 200+ employees, 8000+ Sq.m. factory

② NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040

③ Successful 10000+ customers across the globe

④ 30+ Global Agents covered in Asia, Europe, America, Oceania and Africa

⑤ R&D Center: 3 R&D departments with 25+ professional R&D engineers

⑥ Listed with CE and got 50+ patents

⑦ 30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours

Certification

Exhibition

If you need, please feel free to contact us!

FAQ

Q1: How can I place an order?

A: You can contact any of our sales person for an order.

Please provide the details of your requirements as clear as possible.

So we can send you the offer at the first time.

For designing or further discussion, it is better to contact us with Skype, TradeManger or QQ or WhatsApp or other instant ways, in case of any delays.

Q2: Do you have after-sale service?

A: Yes, Good after-sale service, handling the customer complaint and solve problem for customers.

Q3: Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT Machine, Pick and Place Machine, Reflow Oven, Screen Printer, SMT Production Line and other SMT Products.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.