NeoDen 4 Heads PNP Machine

NeoDen4

4 Heads PNP Machine

The fourth-generation model

Description

Specification

| Product name | NeoDen 4 Heads PNP Machine |

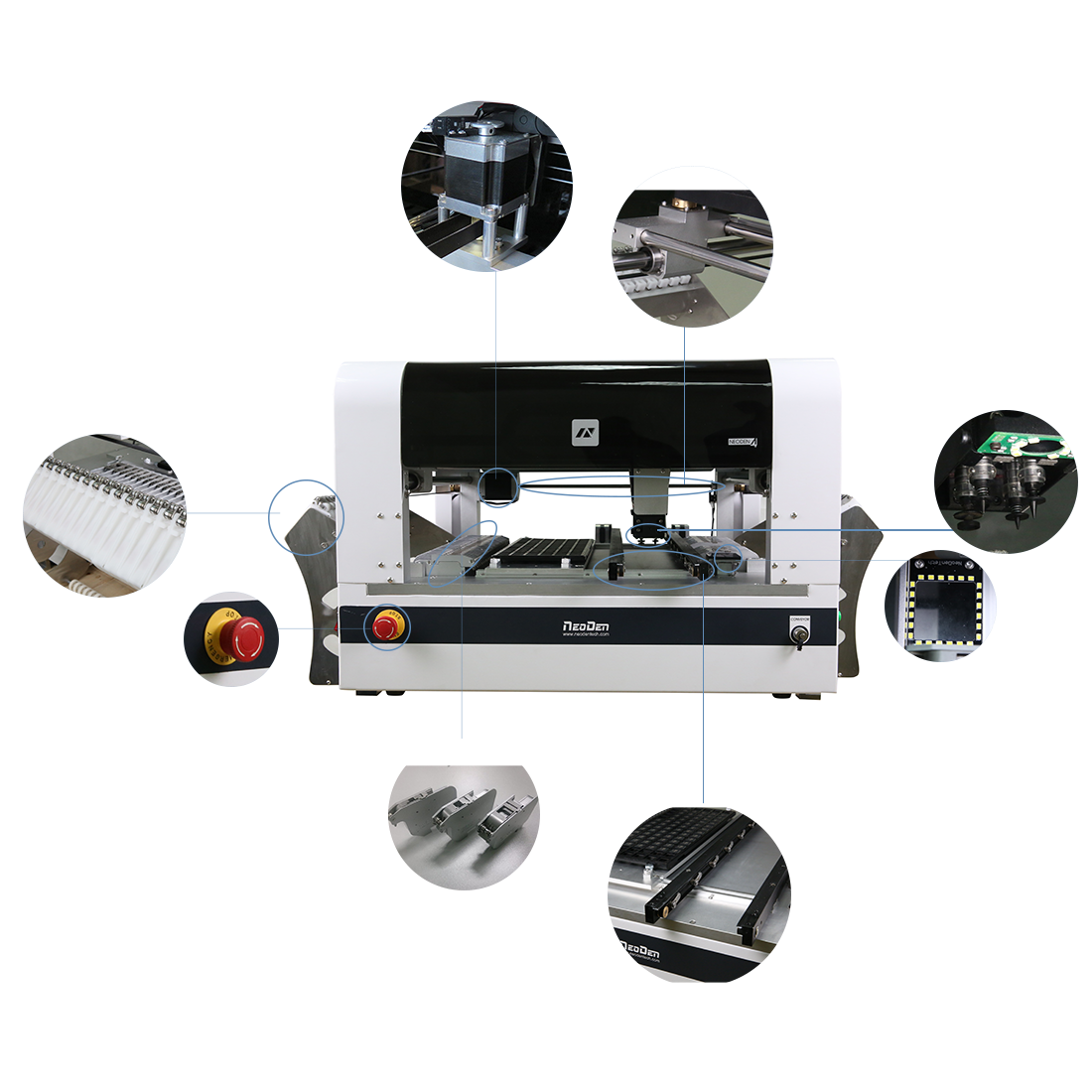

| Machine Style | Single gantry with 4 heads |

| Placement Rate | 4000 CPH |

| External Dimension | L 870×W 680×H 480 mm |

| Max applicable PCB | 290mm*1200mm |

| Feeders | 48pcs |

| Average working power | 220V/160W |

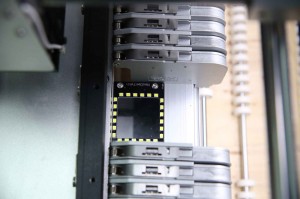

| Component Range | Smallest Size: 0201 |

| Biggest Size: TQFP240 | |

| Max Height: 5mm |

Feature

Component Thickness Limitations

When using tray-fed and short-tape components, the maximum allowable component height is 5mm.

When using tape-and-reel components, we recommend a maximum thickness of 1.8mm for reliable operation.

The upward-looking camera

located on the right side of the machine. When enabled, this camera first ensures that a component is attached to the proper nozzle.

If the camera detects the absence of a component, the machine will make up to two additional attempts to pick a component before asking the user for further instructions.

Once a component has been verified as “picked”, the camera verifies its position relative to the nozzle.

Because SMDs are small and light, and are held only loosely in their packaging, there can be a great deal of variation in the actual position of the component when it arrives in “pick” position and is lifted by the nozzle.

Details

Electric tape-and-reel feeders, vibration feeders and virtual tray feeders are all supported.

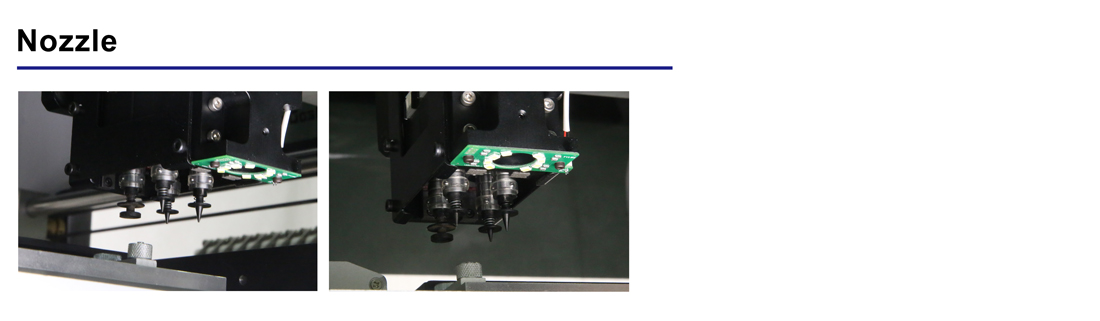

The spring-loaded nozzles simply snap in and pull out of the head.

Any Nozzle can be installed in any of the four locations on the head.

The NeoDen4 features a high-precision, two-camera vision system.

The cameras are made by Micron Technology and are precisely aligned to the nozzles using the single unified configuration/operation application that loads on power-on.

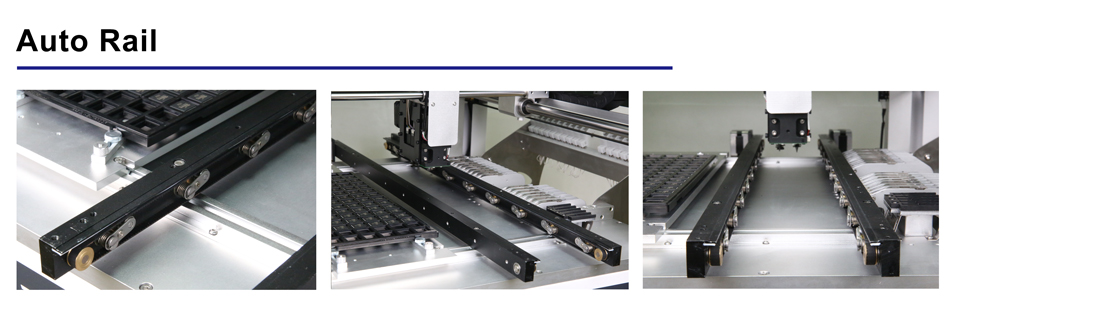

The rail system allows automatic feeding of PCBs, automatic alignment of the board with the camera, and automatic ejection from the front of the machine or the rear.

Rear-ejection is useful when the machine is connected to an optional conveyor that can deliver the finished board directly to the reflow oven or to another NeoDen4.

The NeoDen4 can accommodate up to 48 8mm tape-and-reel feeders on its left and right rails, and any size feeder (8, 12, 16 and 24mm) can be installed in any combination or order on the left and right sides of the machine.

Any area of the table may be used for components awaiting placement, or for the board under manufacture.

Package

If you need, please feel free to contact us for more information.

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010.

Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

① Established in 2010, 200+ employees, 8000+ Sq.m. factory

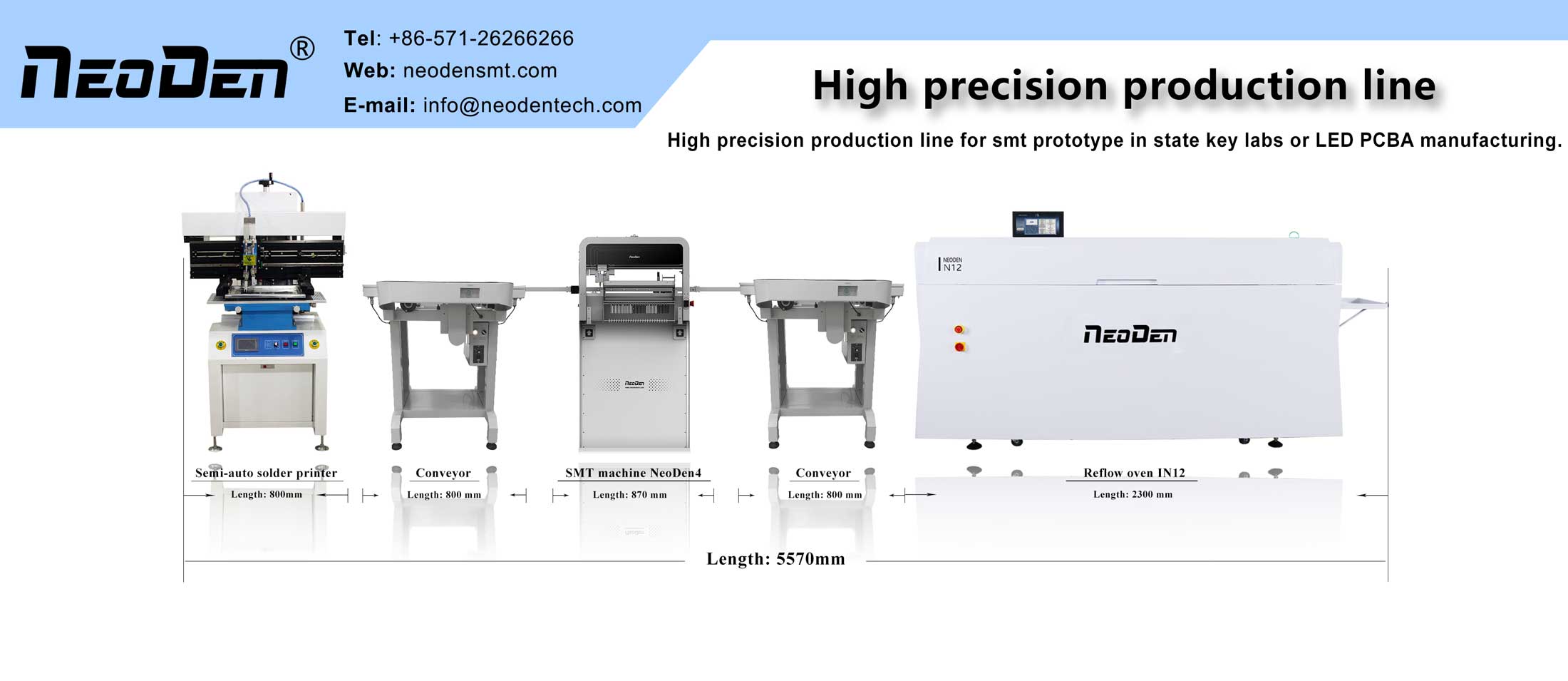

② NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040

③ Successful 10000+ customers across the globe

Certification

Exhibition

FAQ

Q1: Do you provide software updates?

A: Customers who buy our machine, we can offer free upgrades software for you.

Q2: How about the warranty ?

A: We have 2 years warranty for NeoDen4, 1 year for all other model, life time after-sales support.

Q3: Visting factory is allowed or not?

A: Yes, we welcome customers visiting our factory.

Our factory is located Huzhou city, Zhejiang province, China mainland.

One Stop SMT Equipments Manufacturer

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.