NeoDen 3V pick and place machine PCBA

NeoDen 3V pick and place machine PCBA

Description

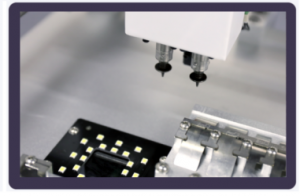

Gantry (2 heads)

Upwards Facing Vision System

Windows XP (NOVA) Operating System

Supports: cut tape, loose, tube and tray components

Approvals: TUV NORD CE

Specification

| Machine Style | Single Gantry with 2 heads | Model | NeoDen 3V standard Version |

| Placement Rate | 3,500CPH | Placement Accuracy | +/-0.05mm |

| Feeder Capacity | Max Tape Feeder: 44pcs (All 8mm width) | Alignment | Stage Vision |

| Vibration Feeder: 5 | Component Range | Smallest Size: 0402 | |

| Tray Feeder: 5-10 | Biggest Size: TQFP144 | ||

| Rotation | +/-180° | Max Height: 5mm | |

| Electricity Supply | 110V/220V | Placement Area | 350x410mm |

| Power | 160W | Machine Size | L820×W650×H410mm |

| Net Weight | 55Kg | Packing Size | L1010×W790×H580 mm |

Detail

Full Vision 2 head system

2 high-precision placement heads

±180° rotation head system

Patented Automatic Peel-box

Feeder Capacity: 24*Tape feeder (all 8mm)

5*Vibration feeder, 10* IC Tray feeder

Flexible PCB positioning

wherever you want to put the PCB

whatever the shape of your PCB

Integrated Controller

More stable performance and easier to do maintenance.

Our Service

1. More Professional service in PNP machine field

2. Better manufacture ability

3. Various payment term to choose: T/T, Western Union, L/C, Paypal

4. High quality/Safe material/Competitive price

5. Small order available

6. Quickly response

7. More safe and fast transport

Accessories

| 1. Pick and Place Machine NeoDen3V-S | 1 | 2. PCB support bar | 4 units |

| 3. PCB support pin | 8 units | 4. Electromagnet | 1 pack |

| 5. Needle | 2 sets | 6. Allen wren set | 1 |

| 7. Tool box | 1 unit | 8. Cleaning needle | 3units |

| 9. Power cord | 1 unit | 10. Double side adhesive tape | 1 set |

| 11. Silicon tube | 0.5m | 12. Fuse(1A) | 2 units |

| 13. 8G flash drive | 1 unit | 14. Reel holder stand | 1 set |

| 15. Nozzle rubber 0.3mm | 5 units | 16. Nozzle rubber 1.0mm | 5 units |

| 17. Vibration feeder | 1 unit |

1. Repair and calibration should be operated by skilled mechanical technician. When replacing parts, please use the part which are supplied by NeoDen. We are not responsible for any accident result from using nonstandard part.

2. In order to prevent electric shock caused by unskilled operation, the electrical repairs, maintenance(including wiring), should be operated by professional electrician or the technical staff from NeoDen or our distributors.

3. Make sure Bolts - Nuts are tighten after repair, calibration or replacing any part.

Click on the picture below to jump to the appropriate product:

FAQ

Q1: This is the first time I use this kind of machine, is it easy to operate?

A: We have English user manual and guide video to teach you how to use the machine . If still have question , pls contact us by email / skype / whatapp / phone / trademanager online service.

Q2: How can I place an order?

A: You can contact any of our sales person for an order. Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For designing or further discussion, it is better to contact us with Skype, TradeManger or QQ or WhatsApp or other instant ways, in case of any delays.

Q3: What about the lead time for mass production?

A: Honestly, it depends on the order quantity and the season you place the order.

Alway 15-30 days based on general order.

About us

Factory

Zhejiang NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products.

With global presence in over 130 countries, the excellent performance, high accuracy and reliability of NeoDen PNP machines make them perfect for R&D, professional prototyping and small to medium batch production. We provide professional solution of one stop SMT equipment.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist on everywhere.

Certification

If you need, please feel free to contact us for more information!

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.