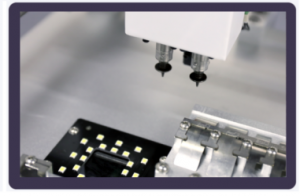

NeoDen 3V desktop pick and place robot

NeoDen 3V desktop pick and place robot Video

NeoDen 3V desktop pick and place robot

Product Description

Specification

| Product name | NeoDen 3V desktop pick and place robot |

| Number Of Heads | 2 |

| Alignment | Vision |

| Rotation | ±180° |

| Placement Rate | 3500CPH(with vision) |

| Feeder Capacity | Tape feeder: 24 (all 8mm) |

| Default Setting: 18x8mm, 4x12mm, 1x16mm | |

| Vibration feeder: 0~5 | |

| Tray feeder: 5~10 | |

| Component Range | Smallest components: 0402 |

| Largest components: TQFP144 | |

| Max height: 5mm | |

| Numbers Of Pumps | 3 |

| Placement Accuracy | ±0.02mm |

| Operate System | WindowsXP-NOVA |

| Power | 160~200W |

| Electricity Supply | 110V/220V |

| N.W/G.W | 55kg/80Kg |

Details

Full Vision 2 Head System

2 high-precision placement heads with ±180°

rotation could satisfy the need of wide range components.

Patented Automatic Peel-box

Patented electromagnetic actuators, you don't need to

get rid of the wasted nylon film manually, which saves

you more time and effort.

Flexible PCB positioning

By using PCB support bars and pins, wherever you want

to put the PCB and whatever the shape of your PCB is,

all can be handled well.

Integrated Controller

More stable performance and easier to do maintenance.

Accessories

1. Pick and Place Machine NeoDen3V: 1

2. PCB support bar: 4units

3. PCB support pin: 8units

4. Electromagnet: 1pack

5. Needle: 2sets

6. Allen wren set: 1

7. Tool box: 1unit

8. Cleaning needle: 3units

9. Power cord: 1unit

10. Double side adhesive tape: 1set

11. Silicon tube: 0.5m

12. Fuse(1A): 2units

13. 8G flash drive: 1unit

14. Reel holder stand:1set

15. Nozzle rubber 0.3mm: 5units

16. Nozzle rubber 1.0mm: 5units

17. Vibration feeder: 1unit

Remark

Provide one-stop SMT assembly production line

FAQ

Q1: Do you provide software updates?

A: Customers who buy our machine,we can offer free upgrades software for you .

Q2: This is the first time I use this kind of machine, is it easy to operate ?

A: We have English user manual and guide video to teach you how to use the machine . If still have question , pls contact us by email / skype / whatapp / phone / trademanager online service.

Q3: What's the way of shipping?

A: These are all heavy machines; we suggest you use cargo ship. But components for mending the machines, air transportation would be fine.

About us

Exhibition

Certification

Factory

If you need, please feel free to contact us!

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.