Massive Selection for Smt Pick And Place Machine Line - Pcb Component Placement Machine NeoDen K1830 – Neoden

Massive Selection for Smt Pick And Place Machine Line - Pcb Component Placement Machine NeoDen K1830 – Neoden Detail:

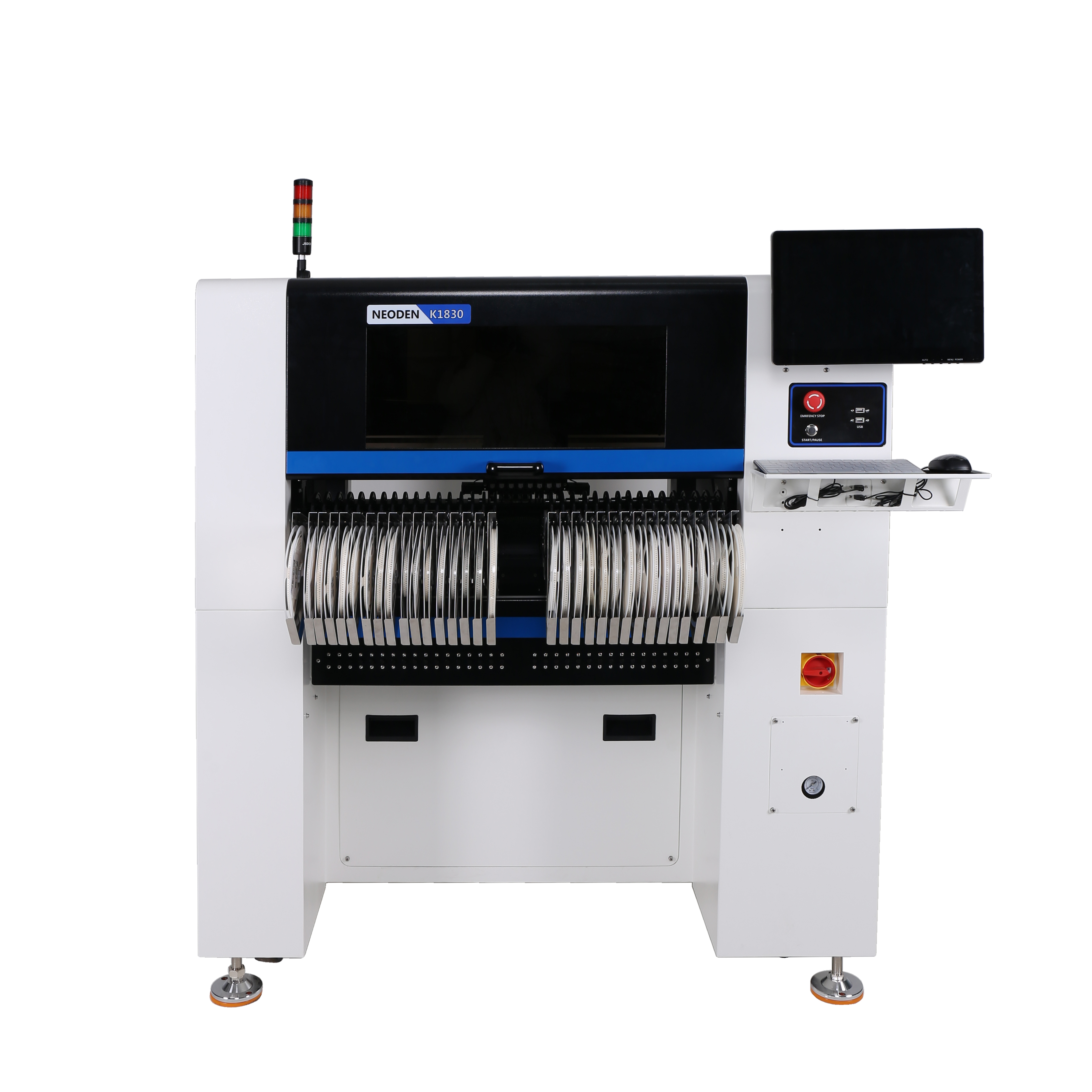

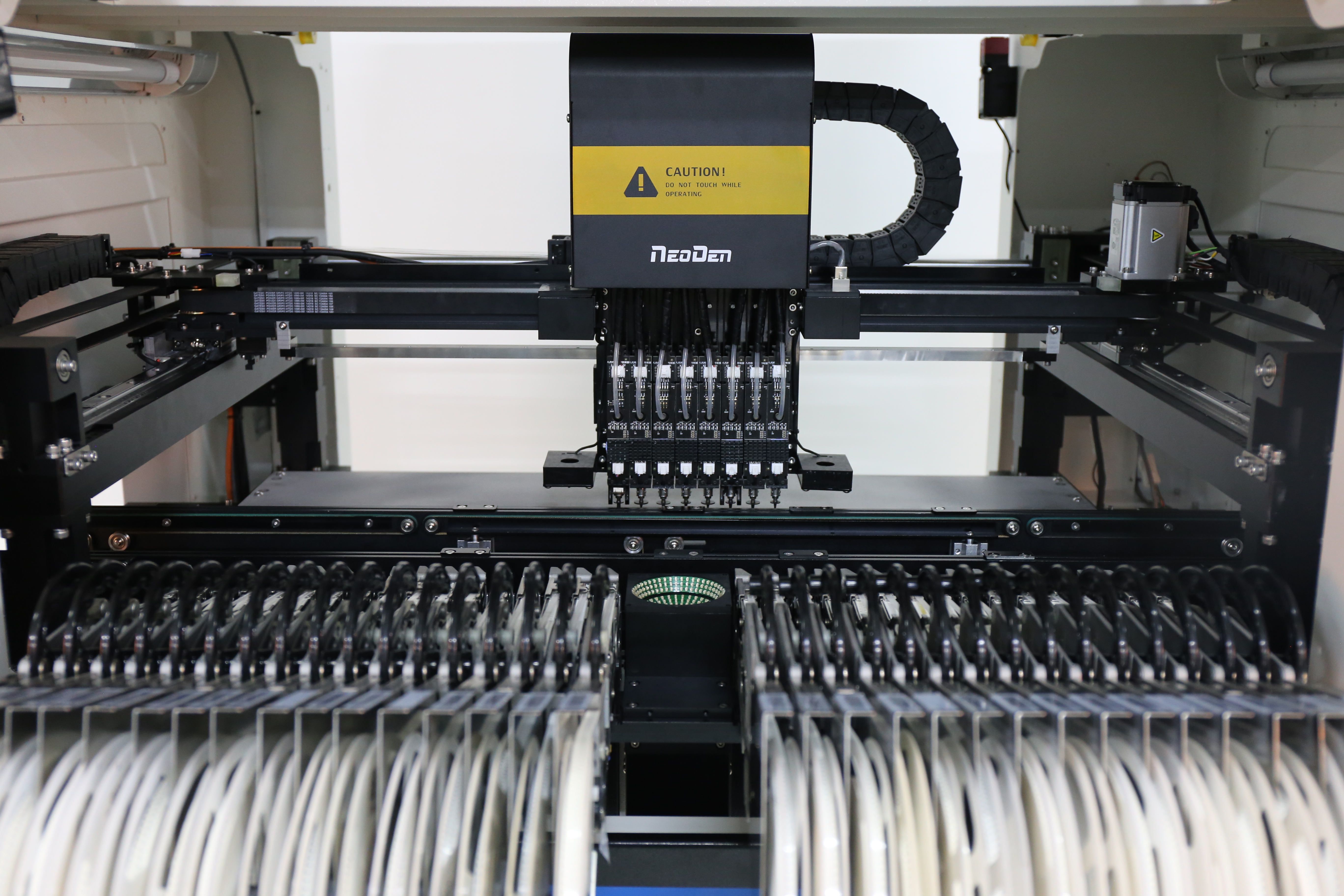

Pcb Component Placement Machine NeoDen K1830

NeoDen K1830 has 8 synchronized nozzles which can make the speed reach to 16000CPH highest.

As the second model of production pnp machine, NeoDen improved the machanical structure and functions. With closed loop servo control system and Linux system, the machine is much more stable and efficiency compare to NeoDen7.

NeoDen K1830 is designed for small-medium productional factories. With affordable price and good mounting function, it could be your prior choice for a medium speed production pick and place machine.

Spotlights

1.

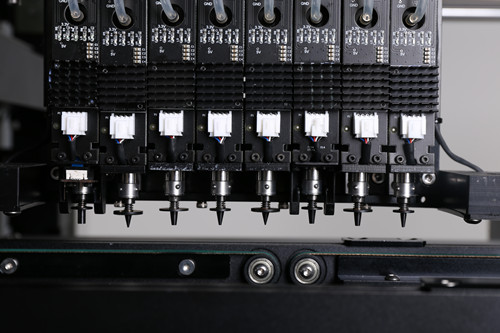

8 Synchronized Nozzles which ensure a repeatable placement accuracy with high speed

2.

Double mark cameras to reach at extreme end feeders for better calibration

High resolution and high speed component camera system improves the overall speed of the machine

3.

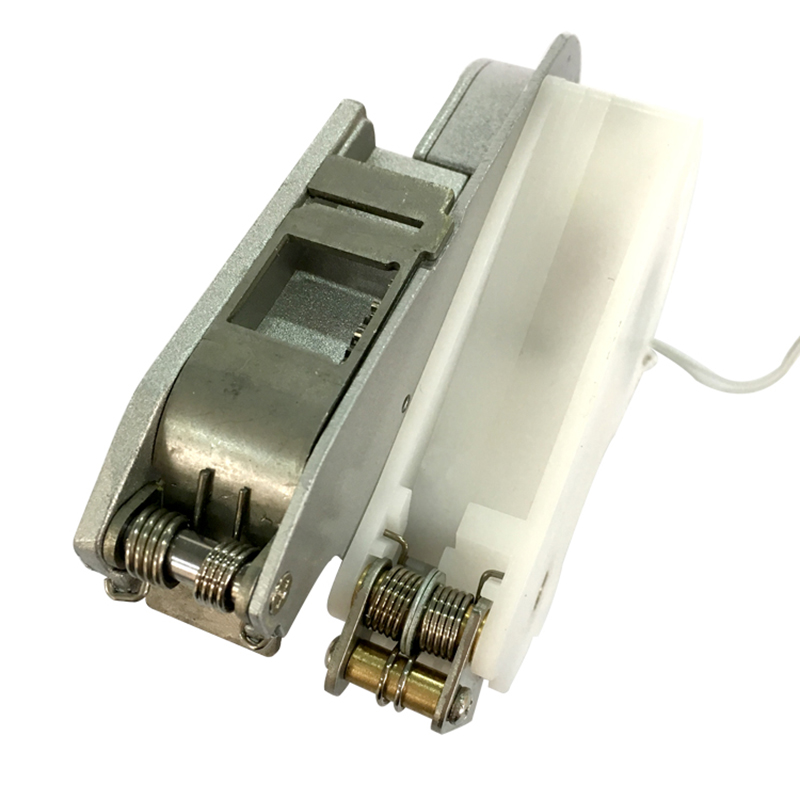

Picking location of pneumatic feeder can be calibrated automatically and promptly,to ensure easy operation and high efficiency

4.

PCB location can be calibrated automatically and promptly,based on the correct and specific placement request

5.

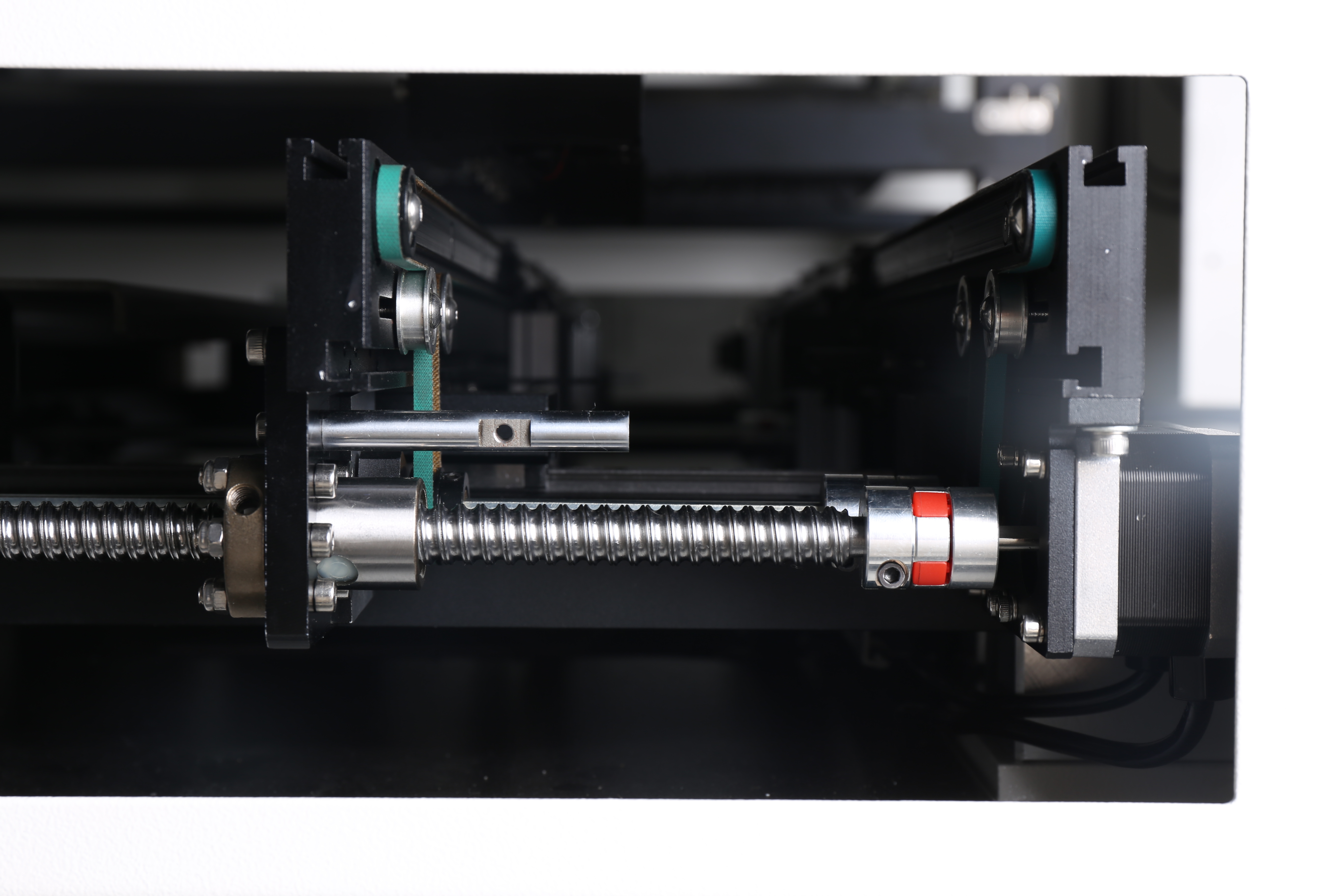

Closed loop Servo control system with feedback makes the machine to function more accurate

6.

Ethernet communication interface for all internal signal travel makes the machine to perform more stable and flexible

Specifications

| Model | NeoDen-K1830 |

| Nozzle head qty | 8 |

| Reel tape feeder qty max. | 66(Electric/Pneumatic) |

| Tray feeder qty | 10 (In Succession) |

| PCB size max. | 540*300mm (under single phase) |

| Component available size | 0201 (electric feeder), 0402-1210 |

| IC available | QFP, SSOP, QFN, BGA |

| Placement accuracy | 0.01mm |

| Component available height max. | 18mm |

| Air supply | >0.6MPa |

| Power | 500W |

| Voltage | 220/ 50HZ & 110V/60HZ |

| Speed max. | 16,000cph |

| Component recognition | High Resolution Flying Vision Camera System |

| PCB Fiducial Recognition | High Precision Mark Camera |

| PCB Loading | Synchronized 3 Stages Internal Conveyor |

| PCB transfer direction | Left→right |

| Net Weight | 280kgs |

| Gross Weight | 360kgs |

| Machine Dimensions | 1288×1062×1291mm |

| Packing Dimensions | 1420×1220×1665mm |

Certificate

Factory

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

We will devote ourselves to providing our esteemed customers with the most enthusiastically thoughtful services for Massive Selection for Smt Pick And Place Machine Line - Pcb Component Placement Machine NeoDen K1830 – Neoden , The product will supply to all over the world, such as: Buenos Aires, Armenia, United States, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.