Manufactur standard Smd Solder Paste Printer - NeoDen SMT solder paste screen printer – Neoden

Manufactur standard Smd Solder Paste Printer - NeoDen SMT solder paste screen printer – Neoden Detail:

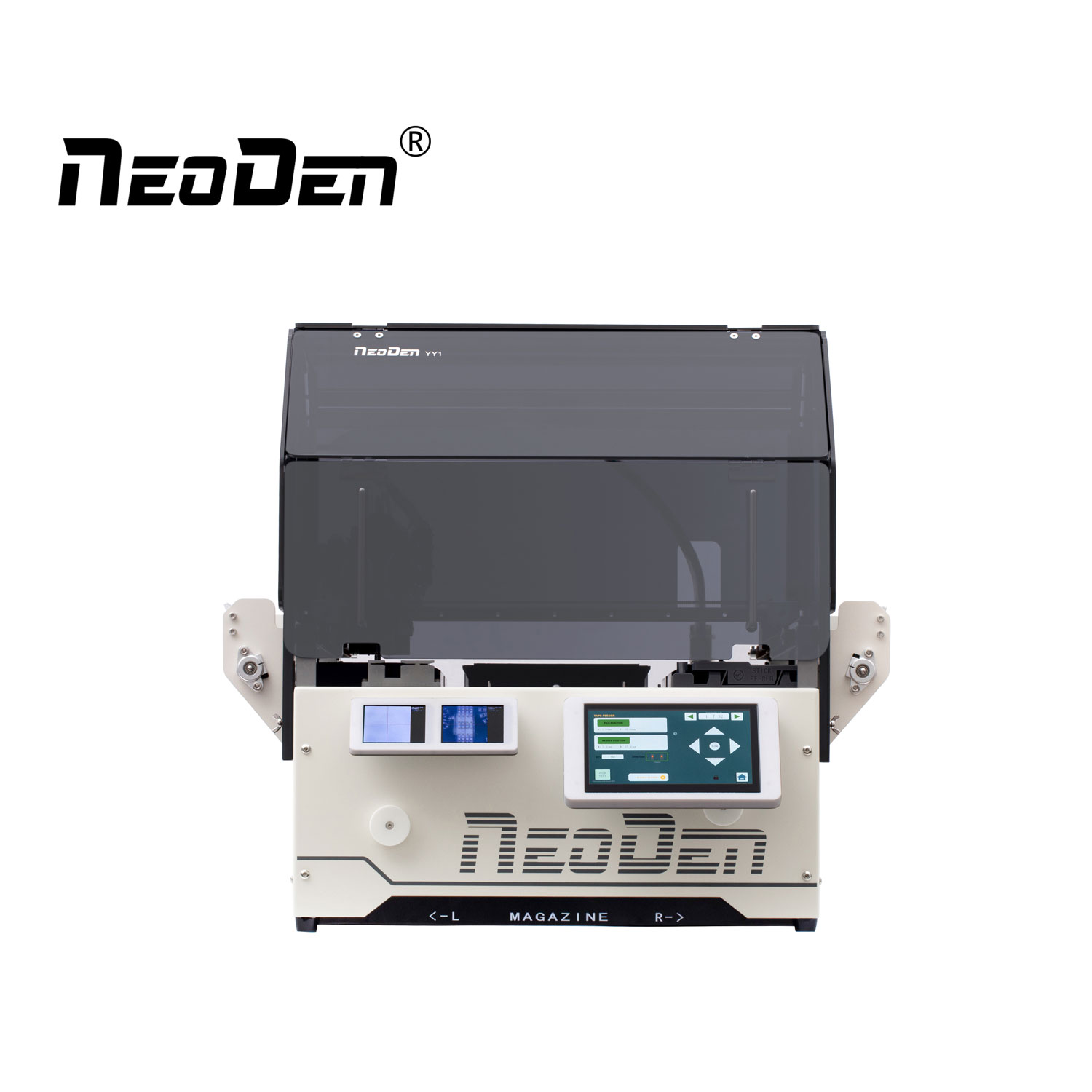

NeoDen SMT solder paste screen printer

Description

Specification

NeoDen SMT solder paste screen printer is easy to learn and use high precision and high stability.

| Product name | NeoDen SMT solder paste screen printer |

| Maximum board size(X x Y) | 450mm x 350mm |

| Minimum board size(X x Y) | 50mm x 50mm |

| PCB thickness | 0.4mm~6mm |

| Warpage | ≤1% Diagonal |

| Maximum board weight | 3Kg |

| Board margin gap | Configuration to 3mm |

| Maximum bottom gap | 20mm |

| Transfer speed | 1500mm/s(Max) |

| Transfer height from the ground | 900±40mm |

| Transfer orbit direction | L-R,R-L,L-L,R-R |

| Machine weight | Appro.1000Kg |

Options Configuration

Stencil’s Solder Paste Remaining Inspecting Function

Real time detection of solder paste margin (thickness) on stencil,intelligent prompt tin adding.

Temperature and humidity control function

Automatic adjustment and supervision of temperature and humidity within the printing press, to ensure the stable physical characteristics of printing materials.

Support MES system seamless docking

It can scan the one-dimensional code or two-dimensional code on the customer PCB and record the relevant information, which can be shared with the customer MES system.

MES system uses two-dimensional code, one-dimensional code, mobile IOT and other technologies to conduct scientific management on the warehouse material preparation and prevention, incoming material picking management, material loading and error prevention, production scheduling, quality traceability, Kanban control, etc. in the SMT production process.

By optimizing the process, we can improve the production efficiency, product quality, shorten the production cycle, reduce the manufacturing cost, prevent mistakes and stupefaction in an all-round way, realize comprehensive and scientific traceability management, help enterprises respond to market changes quickly, and improve their core competitiveness.

Provide one-stop SMT assembly production line

Related products

|

|

|

|

| SMT stencil printer | SMT pick and place machine | Reflow oven IN12 | AOI machine |

FAQ

Q1: This is the first time I use this kind of machine, is it easy to operate ?

A: We have English user manual and guide video to teach you how to use the machine . If still have question , pls contact us by email / skype / whatapp / phone / trademanager online service.

Q2: What products you sell?

A: Our company deal in the following products:

SMT equipment

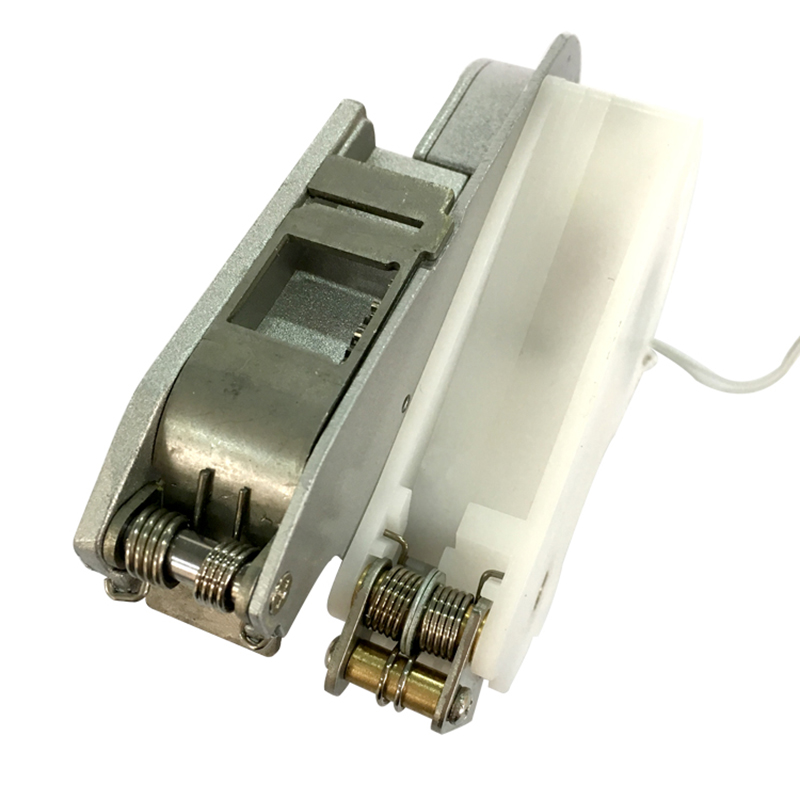

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q3: What’s the way of shipping?

A: These are all heavy machines; we suggest you use cargo ship. But components for mending the machines, air transportation would be fine.

About Us

If you need, please feel free to contact us for more information.

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

To create more value for customers is our business philosophy; customer growing is our working chase for Manufactur standard Smd Solder Paste Printer - NeoDen SMT solder paste screen printer – Neoden , The product will supply to all over the world, such as: Burundi, Sri Lanka, azerbaijan, With high quality, reasonable price, on-time delivery and customized & personalized services to help customers achieve their goals successfully, our company has got praise in both domestic and foreign markets. Buyers are welcome to contact us.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.