Manual Pick and Place Machine

Manual Pick and Place Machine

NeoDen3V

Manual Pick and Place Machine

2 Heads, ±180° rotation head system

Small volume, low power

High speed and accuracy

Stable performance and easy operation

Introduction

Vision system. An up-looking camera identifies and calibrates the different components, and tremendously improves the accuracy of placement from 0402 to TQFP.

Automatic discharging device with electronic magnetic pressure type gear.

Mechanical correction for IC mounting.

Automatic recover function of step out.

Supports remote system upgrade, NeoDen will provide a life-long technical service and system upgrade.

Specification

| Product Name | Manual Pick and Place Machine |

||

| Machine Style | Single Gantry with 2 heads | Model | NeoDen 3V-Advanced |

| Placement Rate | 3,500CPH Vision on/5,000CPH Vision off | Placement Accuracy | +/-0.05mm |

| Feeder Capacity | Max Tape Feeder: 44pcs (All 8mm width) | Alignment | Stage Vision |

| Vibration Feeder: 5 | Component Range | Smallest Size: 0402 | |

| Tray Feeder: 10 | Biggest Size: TQFP144 | ||

| Rotation | +/-180° | Max Height: 5mm | |

| Electricity Supply | 110V/220V | Max Board Dimension | 320x390mm |

| Power | 160~200W | Machine Size | L820×W680×H410mm |

| Net Weight | 60Kg | Packing Size | L1010×W790×H580 mm |

Detail

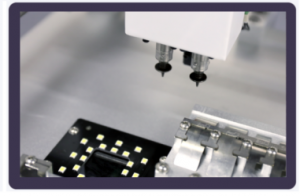

2 Mounting Heads

Full Vision 2 heads system

±180° rotation satisfy the need of wide range components

Patented Automatic Peel-box

Feeder Capacity: 44*Tape feeder(all 8mm),

5*Vibration feeder, 10* IC Tray feeder

Flexible PCB positioning

Using PCB support bars and pins,

wherever to put the PCB, whatever the shape of PCB.

Integrated Controller

More stable performance and easier to do maintenance.

Click on the picture below to jump to the appropriate product:

Our Service

1. Good knowledge on different market can meet special requirements.

2. Real manufacturer with our own factory located in Huzhou, China.

3. Strong professional technical team ensure to produce the top quality products.

4. Special cost control system ensure to provide the most favorable price.

5. Rich experience on SMT area.

About us

Factory

Quick facts about NeoDen

① Established in 2010, 200+ employees, 8000+ Sq.m. factory

② NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040

③ Successful 10000+ customers across the globe

④ 30+ Global Agents covered in Asia, Europe, America, Oceania and Africa

⑤ R&D Center: 3 R&D departments with 25+ professional R&D engineers

⑥ Listed with CE and got 50+ patents

⑦ 30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours

Certification

Exhibition

FAQ

Q1: What about the lead time for mass production?

A: 15-30 working days for mass production.

It depends on your quantity,and we will try our best to meet your needs.

Q2: Can I request to change the form of packaging and transportation?

A: Yes, we can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

Q3: Visting factory is allowed or not?

A: Yes, we welcome customers visiting our factory.

Our factory is located Huzhou city, Zhejiang province,China mainland.

If you need, please feel free to contact us for more information!

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.