LED Chip SMD Mounting Machine

NeoDen K1830 LED chip SMD mounting machine video

NeoDen K1830 LED chip SMD mounting machine

Features

1. Double mark cameras to reach at extreme end feeders for better calibration.

2. Picking location of pneumatic feeder can be calibrated automatically and promptly, to ensure easy operation and high efficiency.

3. PCB location can be calibrated automatically and promptly, based on the correct and specific placement request.

Specification

Product name: NeoDen LED chip SMD mounting machine

Model: NeoDen K1830

Tape width: 8mm, 12mm, 16mm, 24mm, 32mm, 44mm,56mm

IC Tray Capacity: 10

Smallest Component size: 0201 (electronic feeder)

Applicable Components: 0201, Fine-pitch IC, Led Component, Diode, Triode

Component Height Maximum: 18mm

Applicable PCB size: 540mm*300mm (1500 optinal)

Power Supply: 220V, 50Hz (convertible to 110V)

Air source: 0.6MPa

N.W./G.W: 280/360Kgs

Product Detail

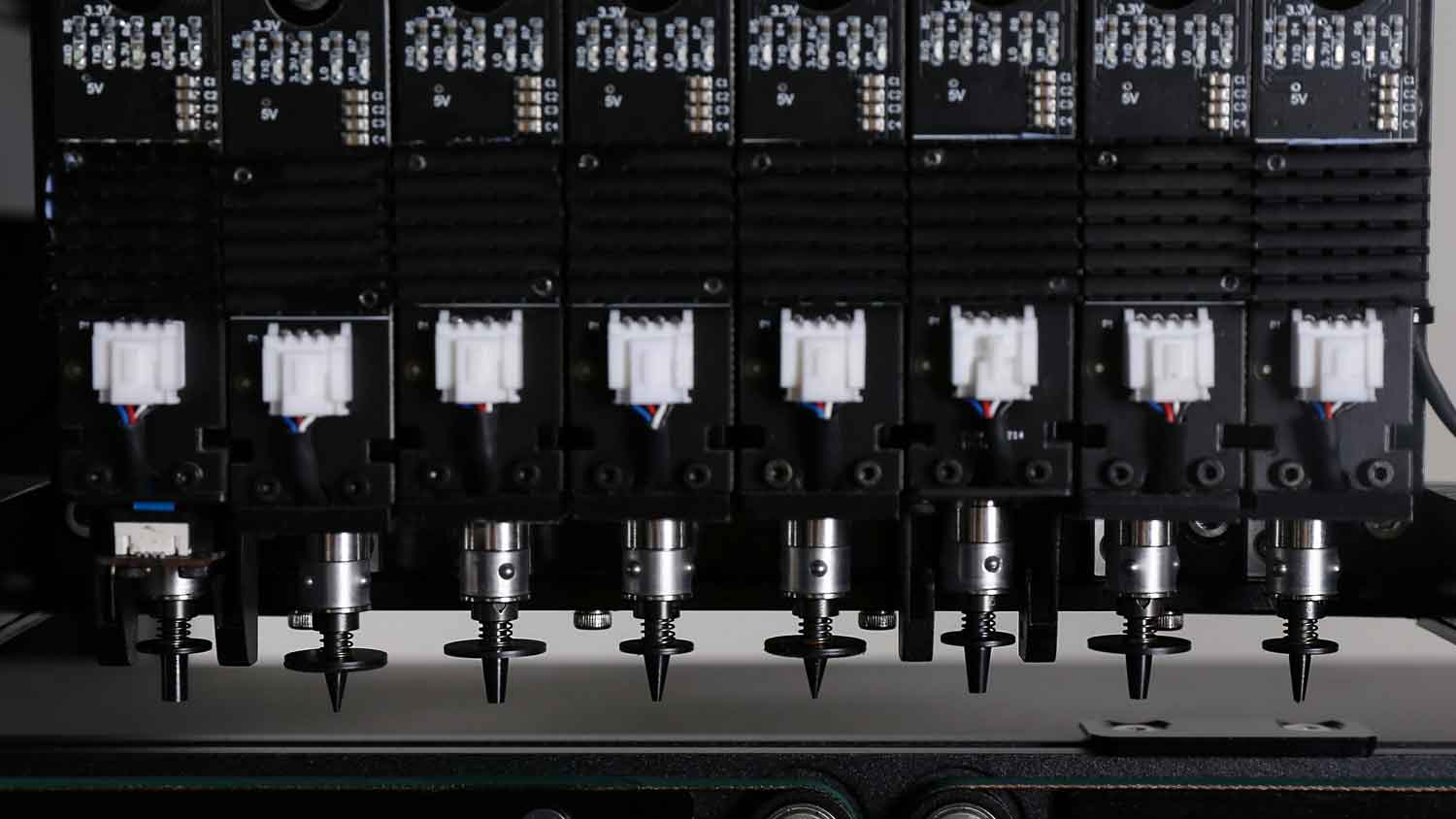

8 heads with Vision enabled

Rotation: +/-180 (360)

High speed repeatable placement accuracy

66 Reel tape feeders

Be calibrated automatically and promptly

Ensure easy operation and high efficiency

Double mark cameras

Better calibration

Improves the overall speed of the machine

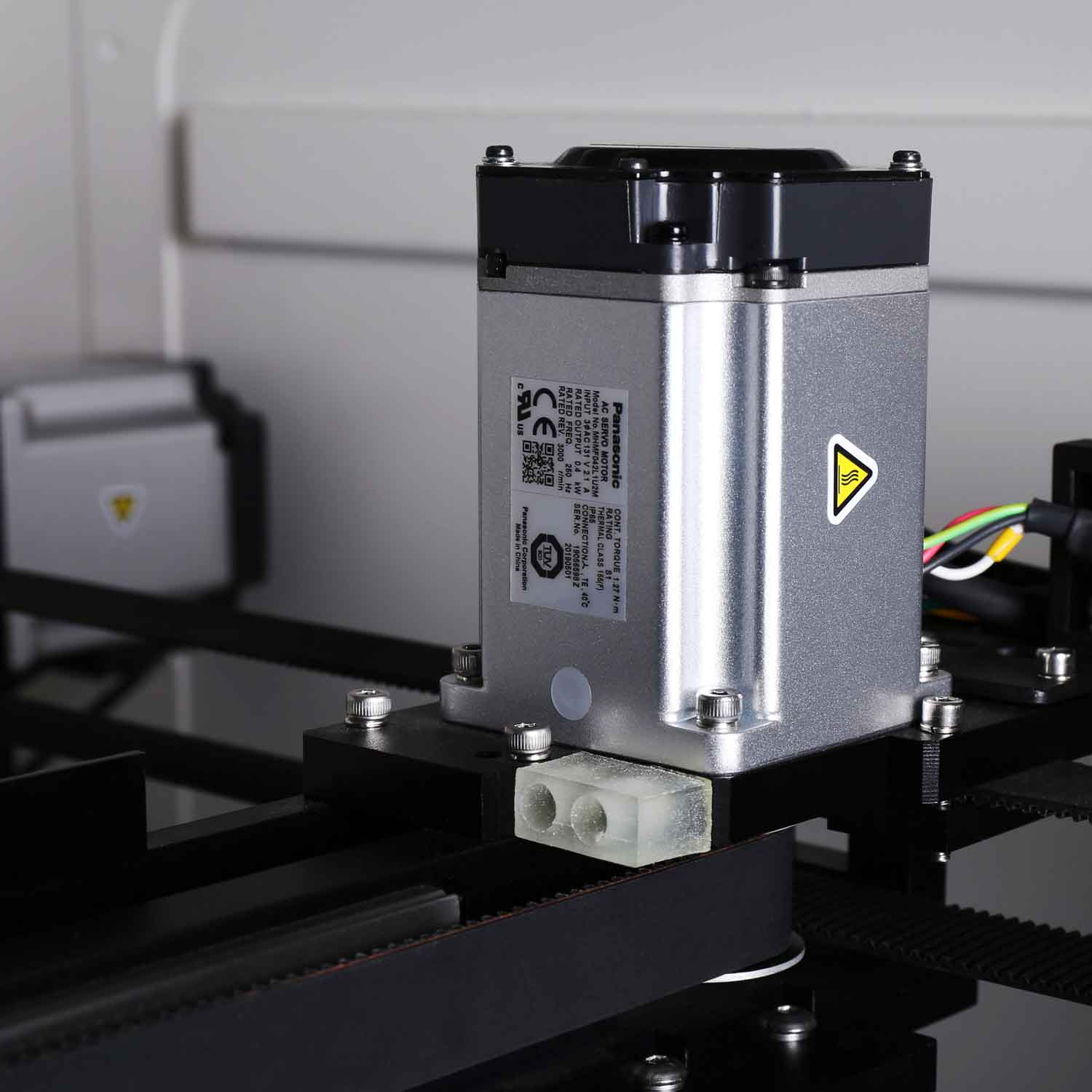

Drive Motor

Panasonic Servo Motor A6

Make the machine to function more accurate

High-definition display

Display size: 12 inch

Makes the machine more convenient to use

Warning light

Triple color of light

Beautiful and elegant indicator design

If you need, please feel free to contact us for more information.

PCB Mark setting

Function:

After finishing mark setting, when the machine is working, the specific position and direction of PCB can confirm via setting mark. Only in this way the next step of mounting work can carry out.

(1) Panelized mark point

It is mainly used for multiple identical PCB boards consistent of the whole board, when place every panel board, the machine will rescan small panel board’s mark point.

(2) Single mark point

It is mainly used for a single PCB board and multiple identical PCB boards consistent of the whole board.

About us

Factory

Quick facts about NeoDen:

① Established in 2010, 200+ employees, 8000+ Sq.m. factory

② NeoDen products: Smart series PNP machine, NeoDen K1830,NeoDen4, NeoDen3V, NeoDen7, ,NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12,Solder paste printer FP2636,PM3040

③ Successful 10000+ customers across the globe

④ 30+ Global Agents covered in Asia, Europe, America, Oceania and Africa

⑤ R&D Center: 3 R&D departments with 25+ professional R&D engineers

⑥ Listed with CE and got 50+ patents

30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours

Certification

Exhibition

FAQ

Q1: How far is your factory from the airport and train station?

A: From airport about 2 hours by car, and from train station about 30 minutes. We can pick up you.

Q2: Can l visit your factory?

A:By all means, we warmly welcome your arrival, Before you take off from your country, please let us know. We will show you the way and arrange time to pick you up if possible.

Q3: Visting factory is allowed or not?

A: Yes, we welcome customers visiting our factory. Our factory is located Huzhou city, Zhejiang province, China mainland.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.