IN6 Desktop SMT Reflow Welding

IN6 Desktop SMT Reflow Welding

6 zones design, light and compact.

Smart control with high sensitivity temperature sensor, the temperature can be stabilized within + 0.2℃.

ESD tray, easy to collect PCB after reflowing, convenient for R&D and prototype.

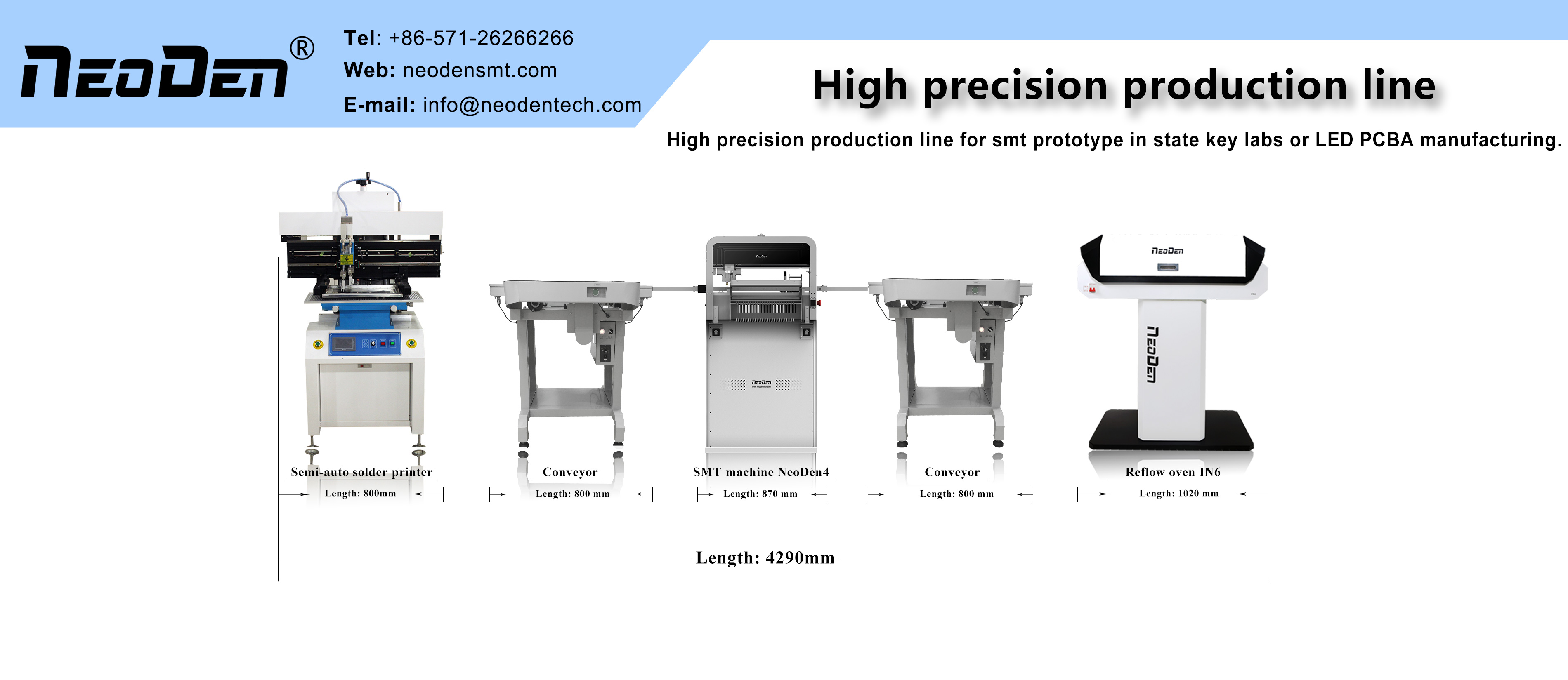

The table-top design of the product makes it a perfect solution for production lines with versatile requirements. It is designed with internal automation that helps operators provide streamlined soldering.

The design implements an aluminum alloy heating plate that increases the energy-efficiency of the system. The internal smoke filtering system improves the product’s performance and reduces harmful output, too.

Specification

| Product Name | IN6 Desktop SMT Reflow Welding |

| Power requirement | 110/220VAC 1-phase |

| Power max. | 2KW |

| Heating zone quantity | Upper3/ down3 |

| Conveyor speed | 5 - 30 cm/min (2 - 12 inch/min) |

| Standard Max Height | 26mm |

| Temperature control range | Room temperature~300 degree celsius |

| Temperature control accuracy | ±0.2 degree celsius |

| Temperature distribution deviation |

±1 degree celsius |

| Soldering width | 260 mm (10 inch) |

| Length process chamber | 680 mm (26.8 inch) |

| Heat-up time | approx. 25 min |

| Dimensions | 1020*507*350mm(L*W*H) |

| Packing Size | 112*62*56cm |

| N.W./ G.W. | 49KG/64kg (without working table) |

Detail

Heating zones

6 zones design, (3 top|3 bottom)

Full hot-air convection

Intelligent control system

Several working files can be stored

Color touch screen

Saving energy and Eco-friendly

Built-in solder smoke filtering system

Reinforced heavy-duty carton package

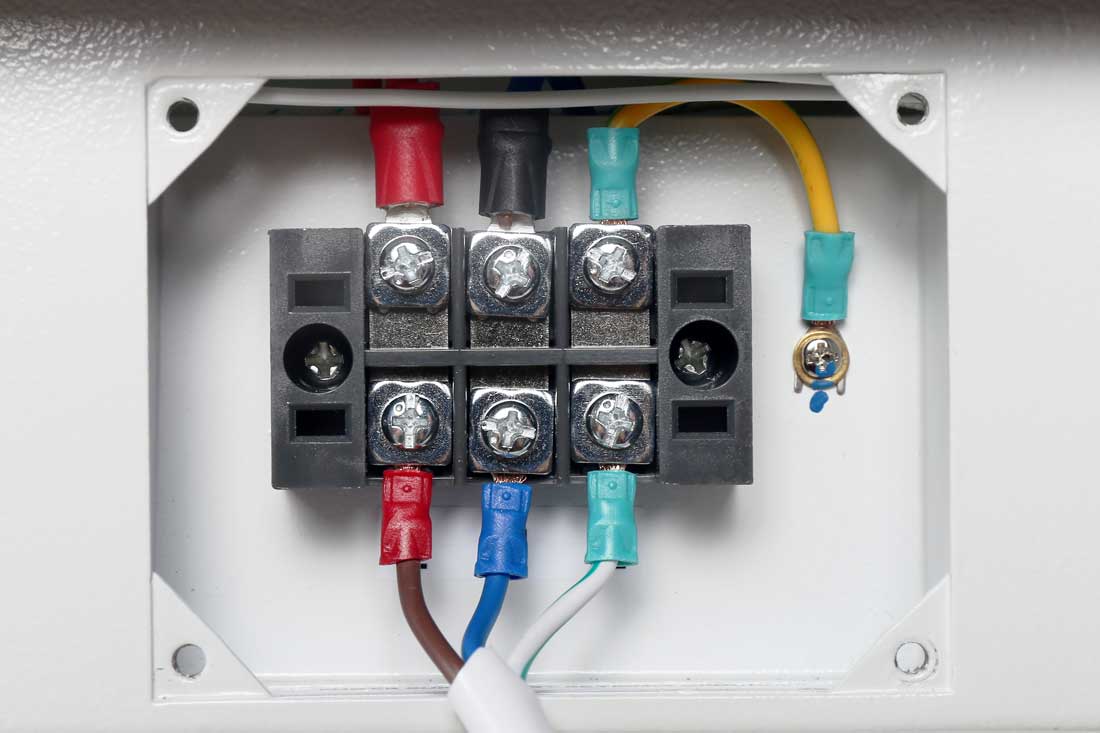

Power Supply Connection

Power supply requirement:110V/220V

Stay away from flammable and explosive

Our Services

1. Good knowledge on different market can meet special requirements.

2. Real manufacturer with our own factory located in Huzhou, China.

3. Strong professional technical team ensure to produce the top quality products.

4. Special cost control system ensure to provide the most favorable price.

5. Rich experience on SMT area.

FAQ

Q1: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry.

If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q2: Do you have after-sale service?

A: Yes, Good after-sale service, handling the customer complaint and solve problem for customers.

Q3: What is your advantage compared with your competitors?

A: (1). Qualified Manufacturer

(2). Reliable Quality Control

(3). Competitive Price

(4). High Efficiency working (24*7hours)

(5). One-Stop Service

About us

Factory

Established in 2010 with 100+ employees & 8000+ Sq.m. factory of independent property rights, to ensure the standard management and achieve the most economic effects as well as saving the cost.

40+ global partners covered in Asia, Europe, America, Oceania and Africa, to successfully serve 10000+ users in all of the world, to ensure the better and faster local service and prompt response.

3 different R&D teams with total 25+ professional R&D engineers, to ensure the better and more advanced developments and new innovation.

NeoDen supplies life-long technical support and service for all of the NeoDen machines, moreover, regular software updates based on the using experiences and actual daily request from the endusers.

Certification

Exhibition

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.