Hot Sale for Manual Chip Mounter - SMD pick and place machine set SMT mounting machine – Neoden

Hot Sale for Manual Chip Mounter - SMD pick and place machine set SMT mounting machine – Neoden Detail:

NeoDen K1830 SMD pick and place machine set video

NeoDen K1830 SMD pick and place machine set

Features

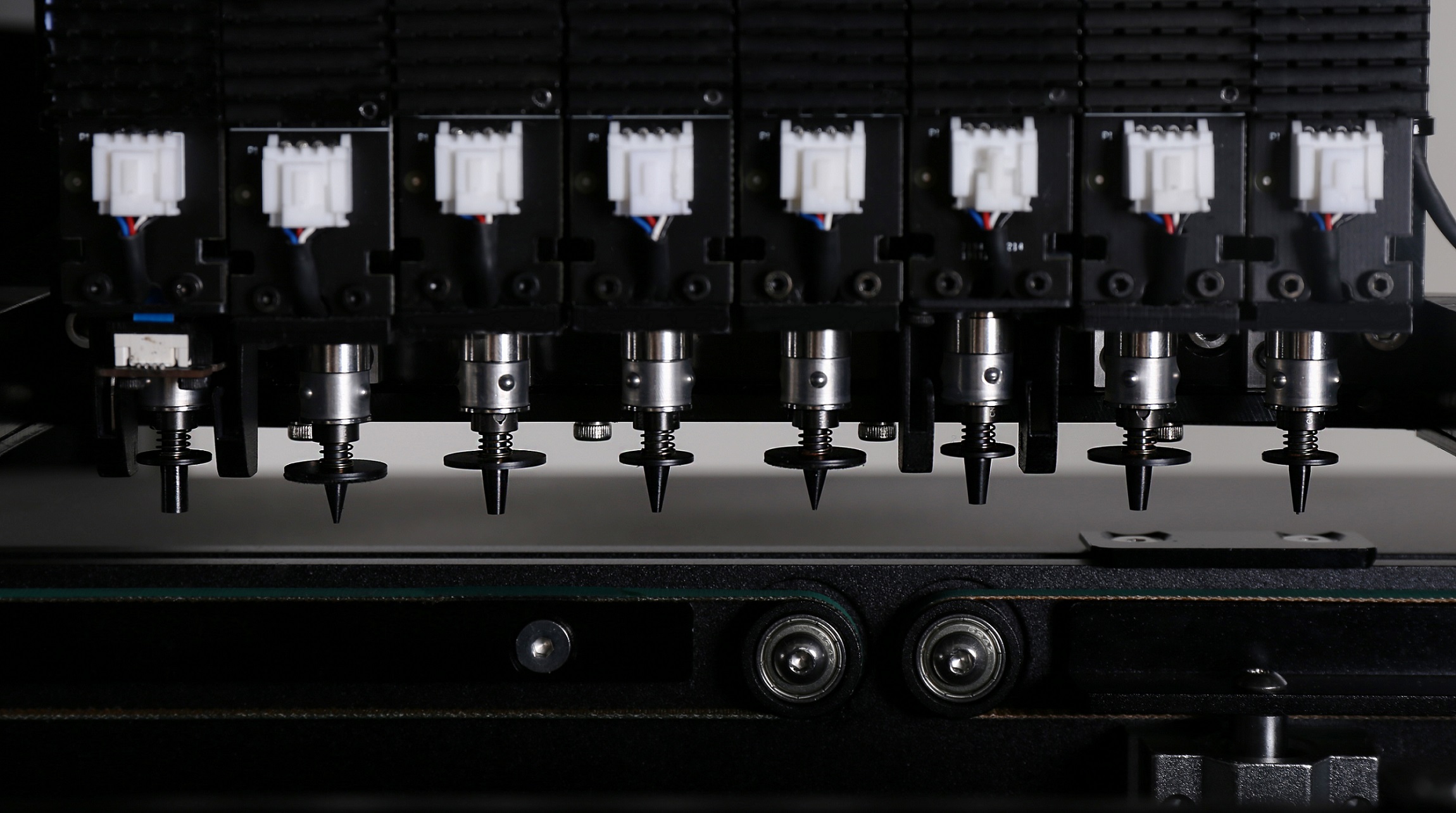

Head

8 Synchronized Nozzles which ensure a repeatable placement accuracy with high speed

System

Machine runs on highly stable and secure Linux operating system

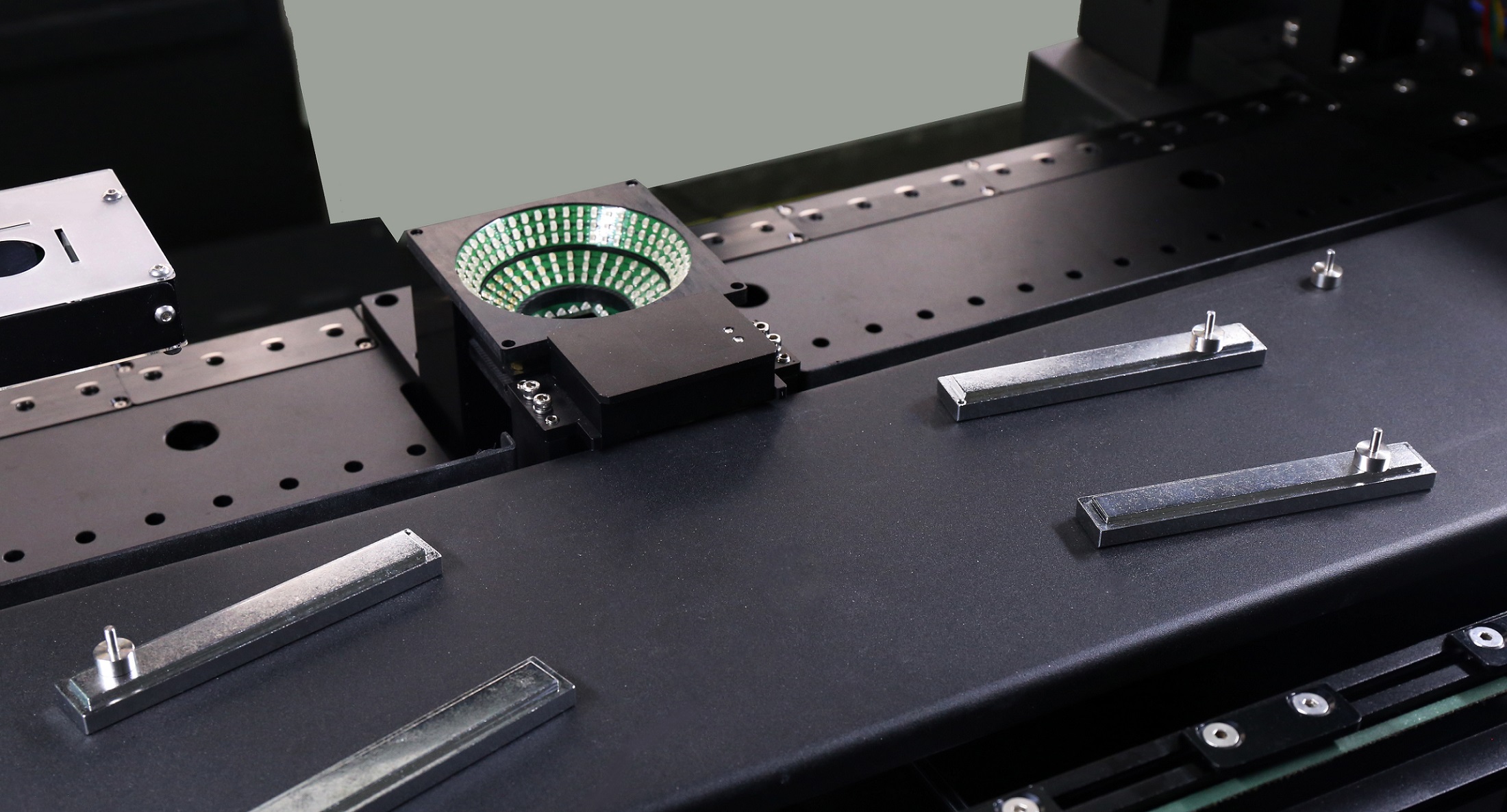

Camera

Double mark cameras to reach at extreme end feeders for better calibration

Interface

Ethernet communication interface for all internal signal travel makes the machine to perform more

stable and flexible

Feeder

Picking location of pneumatic feeder can be calibrated automatically and promptly,to ensure easy

operation and high efficiency

Calibrate

PCB location can be calibrated automatically and promptly,based on the correct and specific placement

request

Product Detail

8 high speed nozzles

1-8 Synchronized Nozzles which ensure a repeatable placement accuracy with high speed.

2-Machine runs on highly stable and secure Linux operating system.

Vision system

1-Double mark cameras to reach at extreme end feeders for better calibration.

2-High resolution and high speed component camera system improves the overall speed of the machine.

66 Reel tape feeders

1-Closed loop Servo control system with feedback makes the machine to function more accurate.

2-Picking location of pneumatic feeder can be calibrated automatically and promptly,to ensure easy operation and high efficiency.

Description

| Product name | NeoDen K1830 SMD pick and place machine set |

| Nozzle Q’ty | 8 |

| Reel Tape Feeder Q’ty(Max) | 66 (Electric / Pneumatic) |

| IC Tray Feeder Q’ty | 10 (In Succession) |

| Max PCB size | 540*300mm(In Single Step) |

| Smallest Component Size | 0201(Electric Feeder Available) |

| IC Packages | QFP, SSOP, QFN, BGA |

| Placement accuracy | 0.01mm |

| Max Component Height | 18mm |

| Max Placement Speed | 16,000CPH |

| Component Recognition | High Resolution Flying Vision Camera System |

| PCB Fiducial Recognition | High Precision Mark Camera |

| PCB Loading | Synchronized 3 Stages Internal Conveyor system |

| PCB Transfer Direction | Left→Right |

| Air Supply | >0.6MPa |

| Power | 500W |

| Voltage | 220V/50HZ & 110V/60HZ |

| Net Weight | 280kgs |

| Gross Weight | 360kgs |

| Machine Dimensions | 1288×1062×1291mm(Without Tri-color Light) |

| Packing Dimensions | 1420×1220×1665mm |

Notes

1. The pick and place machine is a precision equipment. In the installation position of the machine, it is necessary to carry out horizontal correction before and after the equipment to prevent the uneven operation of the equipment from damaging the service life of the equipment.

2. Connect and fix the equipment interface before and after the equipment, and connect and fix the ground wire.

3. The access power must meet the requirements of power identification.

If you need, please don’t hesitate to send your inquiry.

Provide one-stop SMT assembly production line

Related Products

|

|

|

| Stencil printer FP2636 | Automatic conveyor J12 | Reflow Oven IN6 |

FAQ

Q1: Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT Machine, Pick and Place Machine, Reflow Oven, Screen Printer, SMT Production Line and other SMT Products.

Q2: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q3: Is it hard to use these machines?

A: No,not hard at all.For our previous clients,at most 2 days is enough to learn to operate the machines.

About us

Exhibition

Certification

Factory

If you need, please don’t hesitate to send your inquiry.

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

We know that we only thrive if we could guarantee our combined price tag competiveness and quality advantageous at the same time for Hot Sale for Manual Chip Mounter - SMD pick and place machine set SMT mounting machine – Neoden , The product will supply to all over the world, such as: Sydney, Manchester, French, We are introduced as a one of the growing manufacture supplier and export of our products. We have a team of dedicated trained professional who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.