Hot Fully Automatic Pick And Place – Neoden4 – Neoden

Hot Fully Automatic Pick And Place – Neoden4 – Neoden Detail:

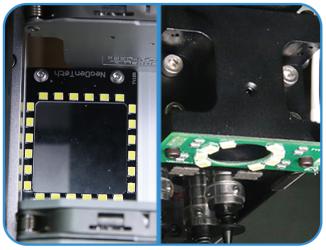

Dual vision system(up-looking and down-looking cameras), equip with high speed industry CCD cameras can help to identify and calibrate the four picking components at one time, highly improved accuracy of placement from 0201 to BGA

NEODEN independent research and development on-line dual rails:

A.Support connect to conventional conveyor directly,help reach the goal of continuous automatic feeding the boards

B.Set the feeding position at anywhere shorten the mounting route

C.Bases on NeoDen Mark point relocated technology, can mount overlong boards easily

Electronic feeders,adopts feeding error corrections technique to help smooth the picking and reduce the deviation

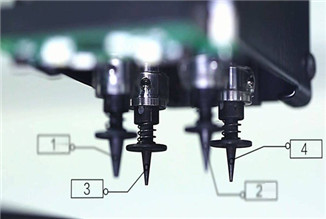

Four high precision nozzles, after calibration by vision software, it can reach to pick and place four components at one time with 360 degrees rotation at -180 to180

General conveyor is supported,to help users achieve automatic production without labors at all

Industrial PC motherboard,32G solid state drives, read/write faster and more stable, with power-off protection function

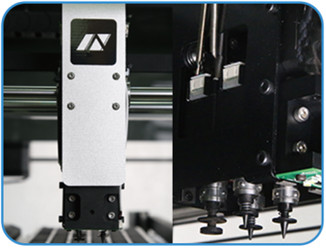

Newly designed mounting head that adopts suspended, fully symmetric and high degree of coupling way, to ensure it can mount components with higher space, more gentle and more accurate

Supports remote system upgrade, NeoDen will provide a life-long technical service and system upgrade

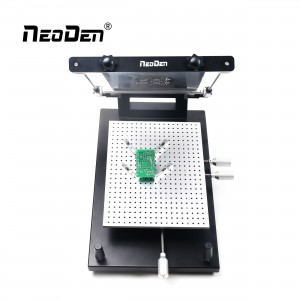

Lightweight body and stable quality suit for customers who want to start small-medium production, lab research and prototyping

Why Choose

1.Light weight body,occupy small area

2.User friendly interface,no need professional SMT engineer,entry-level device

3.High integrated,no need extra pump or any supporting facility

4.High accuracy and reliability,make up the defection of manual work

5.Low cost,reduce expense to own a professional automatic SMT production line

6.International express with door to door service,3-5 working days delivery

7.Especial for laboratory research and development,samples,to avoid any patents and designs revealment

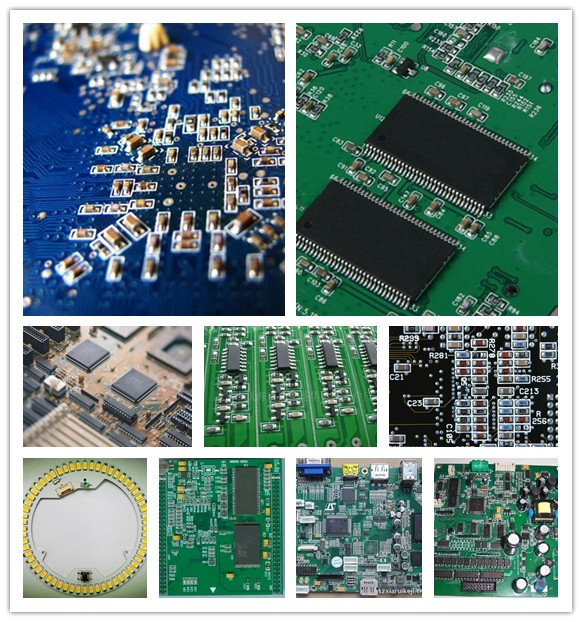

Sample Boards from Few Customers

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

We believe that long expression partnership is often a result of top of the range, value added service, prosperous encounter and personal contact for Hot Fully Automatic Pick And Place – Neoden4 – Neoden , The product will supply to all over the world, such as: Peru, Ghana, France, You can always find the products you need in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We are looking forward to work with you for a win-win situation.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.