Hot Air PCB Reflow Machine

Hot Air PCB Reflow Machine

1. 6 zones design, light and compact.

2. Smart control with high sensitivity temperature sensor, the temperature can be stabilized within + 0.2℃.

3. Original high-performance aluminum alloy heating plate instead of heating pipe, both energy-saving and.

4. The new model has bypassed the need for a tubular heater, which provides even temperature distribution throughout the reflow oven. By soldering PCBs in even convection, all components are heated at the same rate.

5. An internal temperature sensor ensures full control of the heating chamber and can reach optimal temperatures in as little as fifteen minutes.

6. The design implements an aluminum alloy heating plate that increases the energy-efficiency of the system. The internal smoke filtering system improves the product’s performance and reduces harmful output, too.

Specification

| Product Name | Hot Air PCB Reflow Machine |

| Power requirement | 110/220VAC 1-phase |

| Power max. | 2KW |

| Heating zone quantity | Upper3/ down3 |

| Conveyor speed | 5 - 30 cm/min (2 - 12 inch/min) |

| Standard Max Height | 26mm |

| Temperature control range | Room temperature~300 degree celsius |

| Temperature control accuracy | ±0.2 degree celsius |

| Temperature distribution deviation |

±1 degree celsius |

| Soldering width | 260 mm (10 inch) |

| Length process chamber | 680 mm (26.8 inch) |

| Heat-up time | approx. 25 min |

| Dimensions | 1020*507*350mm(L*W*H) |

| Packing Size | 112*62*56cm |

| N.W./ G.W. | 49KG/64kg (without working table) |

Detail

Heating zones

6 zones design, (3 top|3 bottom)

Full hot-air convection

Intelligent control system

Several working files can be stored

Color touch screen

Saving energy and Eco-friendly

Built-in solder smoke filtering system

Reinforced heavy-duty carton package

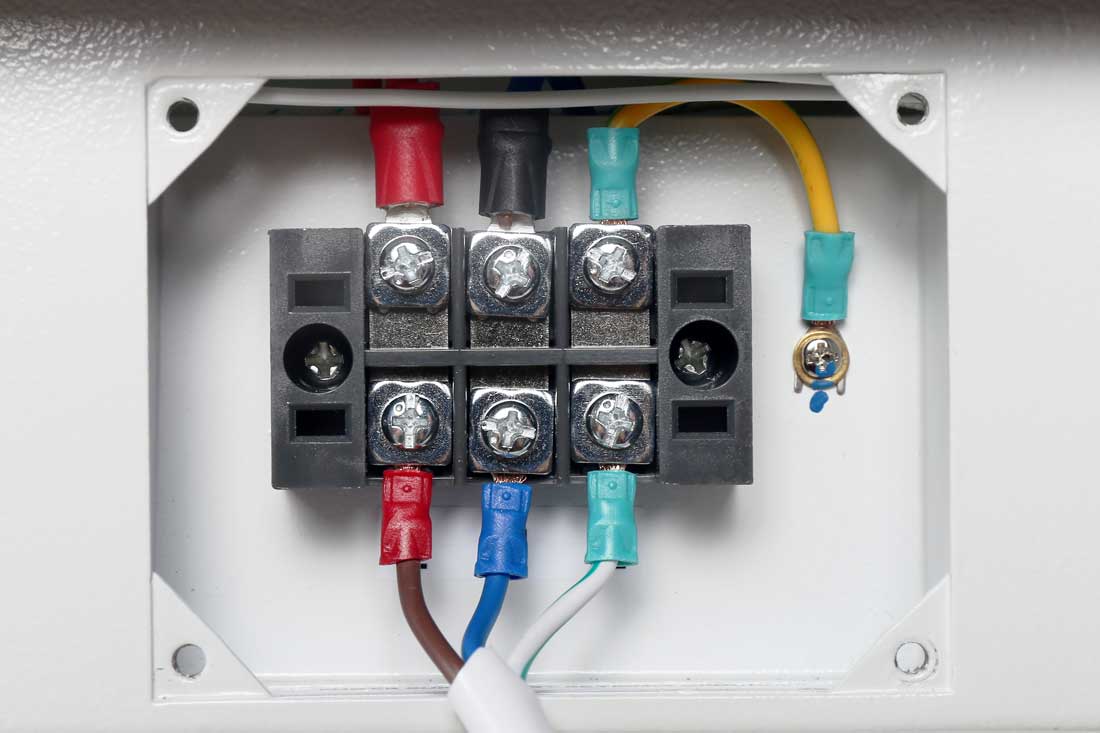

Power Supply Connection

Power supply requirement:110V/220V

Stay away from flammable and explosive

Quality control

We have QC person stay on the production lines do to the inspection.

All products must have been inspected before delivery.

We do inline inspection and final inspection.

1. All raw material checked once it arrive our factory.

2. All pieces and logo and all details checked during production.

3. All packing details checked during production.

4. All production quality and packing checked on final inspection after finished.

FAQ

Q1: What about the lead time for mass production?

A: Honestly, it depends on the order quantity and the season you place the order.

Alway 15-30 days based on general order.

Q2: How your quality guarantee?

A: We have 100% quality guarantee to customers.

We will be responsible for any quality problem.

Q3: What’s your tem of the delivery?

A: Our ordinary delivery term is FOB Shanghai.

We also accept EXW, CFR, CIF, DDP, DDU etc.

We’ll offer you the shipping charges and you can choose the one which is the most convenient and effective for you.

About us

Factory

Quick facts about NeoDen

① Established in 2010, 200+ employees, 8000+ Sq.m. factory

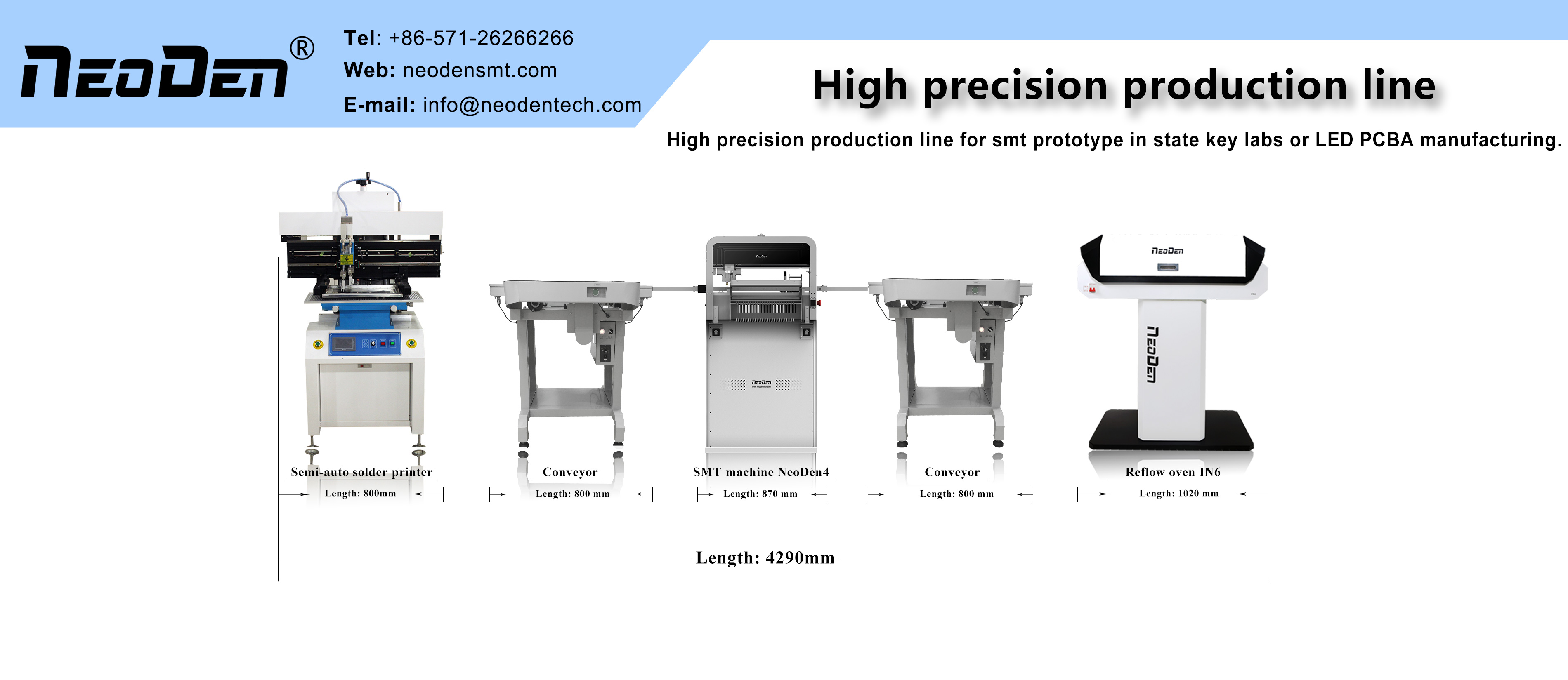

② NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040

③ Successful 10000+ customers across the globe

④ 30+ Global Agents covered in Asia, Europe, America, Oceania and Africa

⑤ R&D Center: 3 R&D departments with 25+ professional R&D engineers

⑥ Listed with CE and got 50+ patents

⑦ 30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours

Certification

Exhibition

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.