High Performance Smt Reflow Oven Pcb Conveyor – PCB Fast Prototype Reflow Oven IN6 – Neoden

High Performance Smt Reflow Oven Pcb Conveyor – PCB Fast Prototype Reflow Oven IN6 – Neoden Detail:

IN6 is a newly designed and manufactured reflow oven by NeoDen Tech.

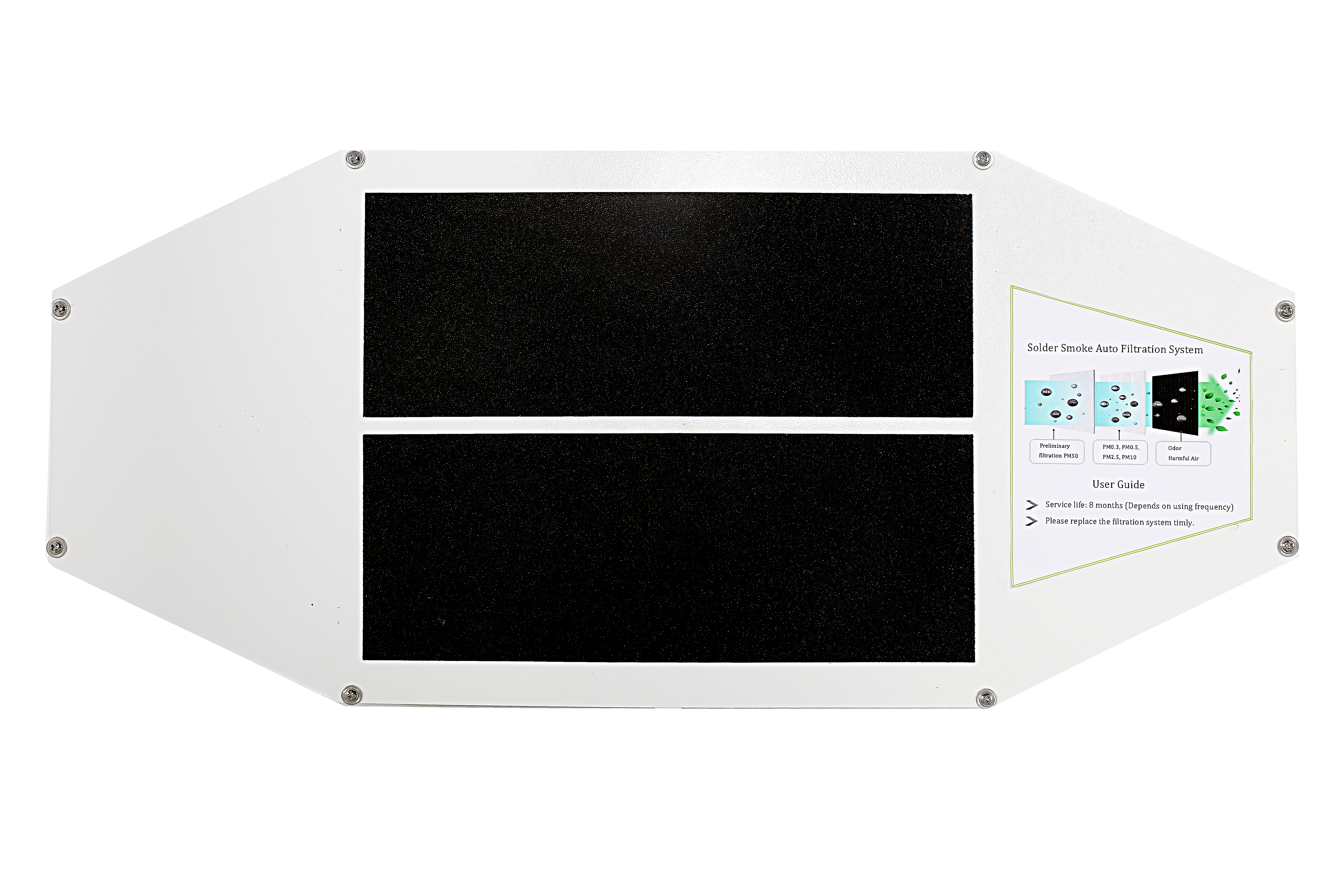

NeoDen IN6 has 6 temperature zones, a built-in welding smoke filtering system, working file memory function and heat-up reminder, which makes it intelligent and innovative and compact.

NeoDen IN6 is a desktop soldering machine with excellent soldering performance. Different from the traditional technology, NeoDen IN6 adopt our original design of built-in soldering smoke filtering system, which is more eco-friendly. With 6 heating zones (upper3/down3), NeoDen IN6 support most of regular components, LED and ICs.

Spotlights

1.Full heat convection, excellent soldering performance.

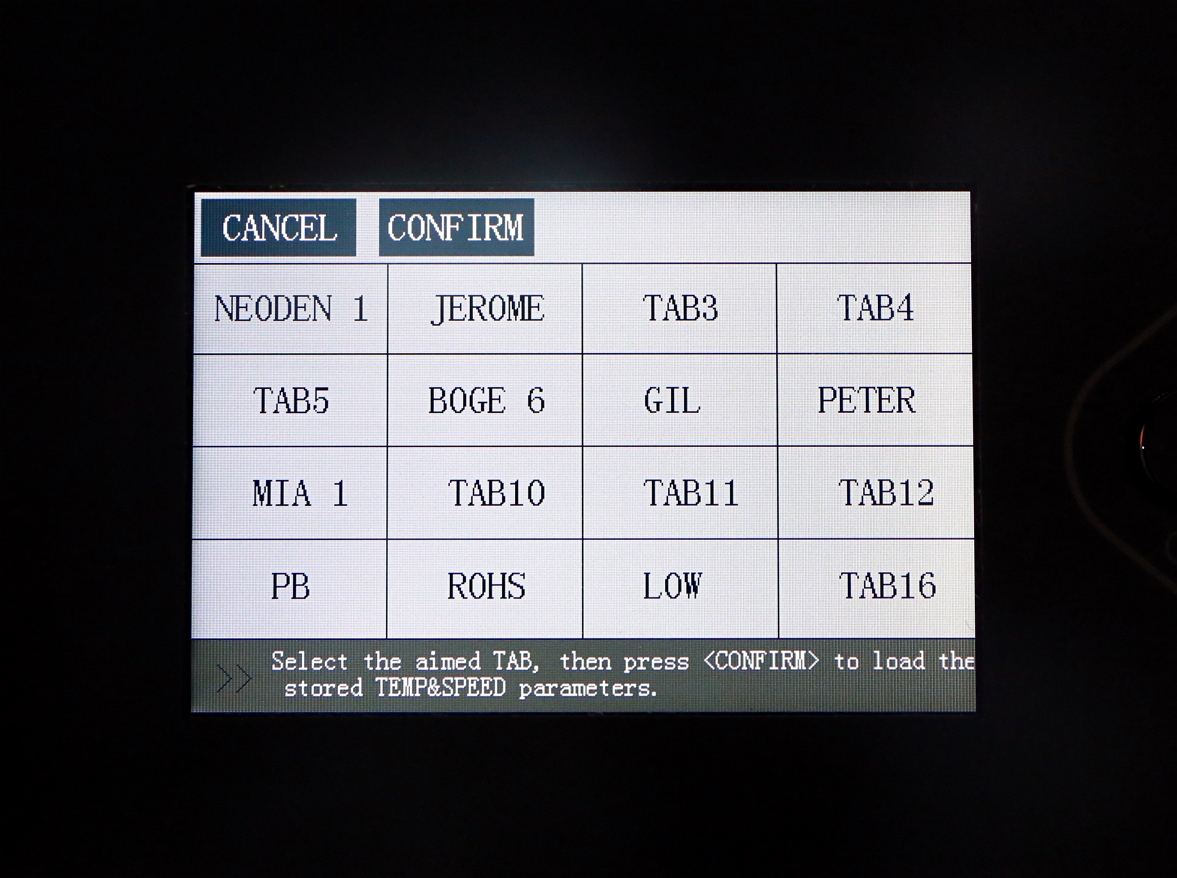

2. 16 working files can be saved

flexibly convert from Celsius to Fahrenheit, easy to understand

3. Built-in welding smoke filtering system

Elegant appearance and eco-friendly

4. Approved by TUV NORD CE

Qualified and reliable

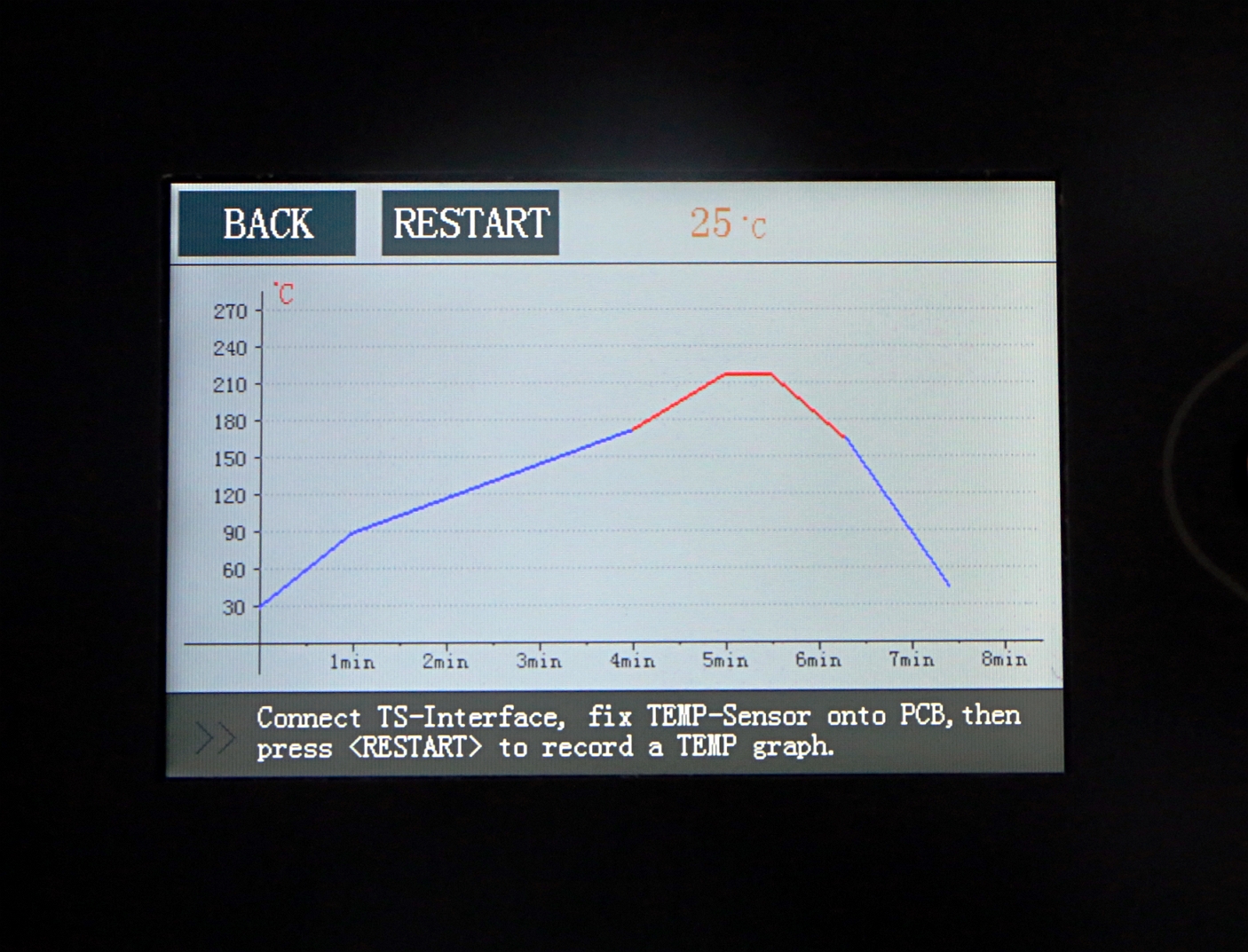

5. PCB soldering temperature curve

PCB soldering temperature curve can be displayed based on real-time measurement

Exhibition

Specifications

| Model | IN6 |

| Heating Zone Quantity | upper3/down3

(2 pre-heat and 1 reflow zone) |

| Heating Type | nichrome wire and aluminum alloy heating |

| Cooling Zone Quantity | 1 |

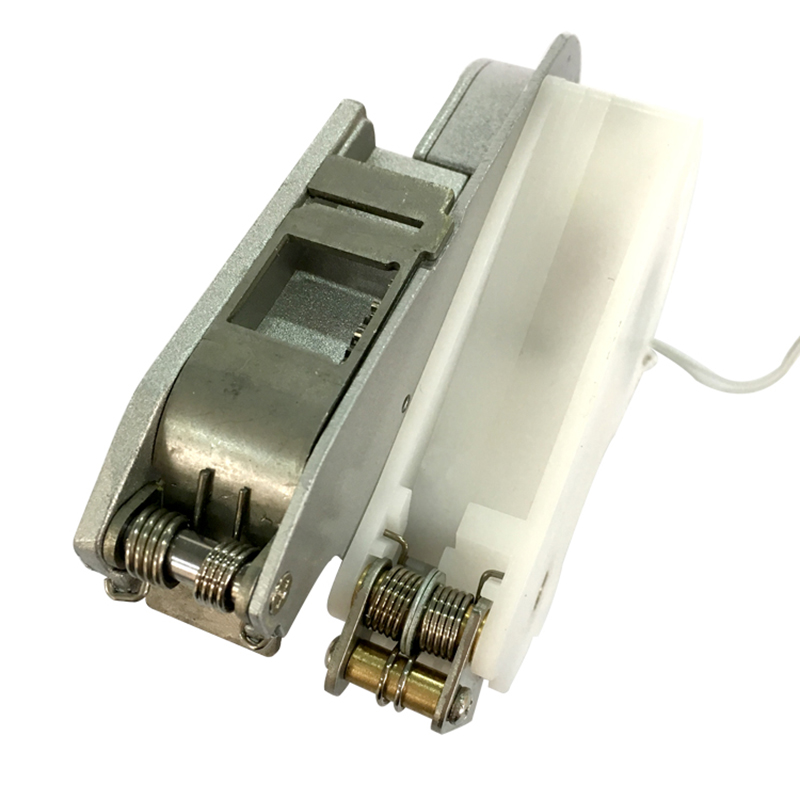

| Conveyor Speed | 15 – 60 cm/min (6 – 23 inch/min) |

| Temperature Range | Room temperature~300℃ |

| Temperature Accuracy | ±0.5℃ |

| PCB Temperature Deviation | ±1℃ |

| Soldering Width | 260 mm (10 inch) |

| Length Process Chamber | 680 mm (26.8 inch) |

| Heat-up Time | approx. 15 min |

| Standard Max Height (mm) | 26mm |

| Operation Direction | left→right |

| Electricity Supply | AC110v/220v single phase |

| Max Rated Power | 2000w |

| Working Power | approx.700w |

| Machine Size | 1020*507*350mm |

| Net Weight | 49KG |

Certificate

Factory

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of High Performance Smt Reflow Oven Pcb Conveyor – PCB Fast Prototype Reflow Oven IN6 – Neoden , The product will supply to all over the world, such as: Nigeria, Greenland, Argentina, Our company is an international supplier on this kind of merchandise. We offer an amazing selection of high-quality products. Our goal is to delight you with our distinctive collection of mindful products while providing value and excellent service. Our mission is simple: To provide the best products and service to our customers at the lowest prices possible.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!