High Performance Pick And Place Automation - Pick and place machine tabletop for PCB macking – Neoden

High Performance Pick And Place Automation - Pick and place machine tabletop for PCB macking – Neoden Detail:

NeoDen pick and place machine tabletop for PCB macking Video

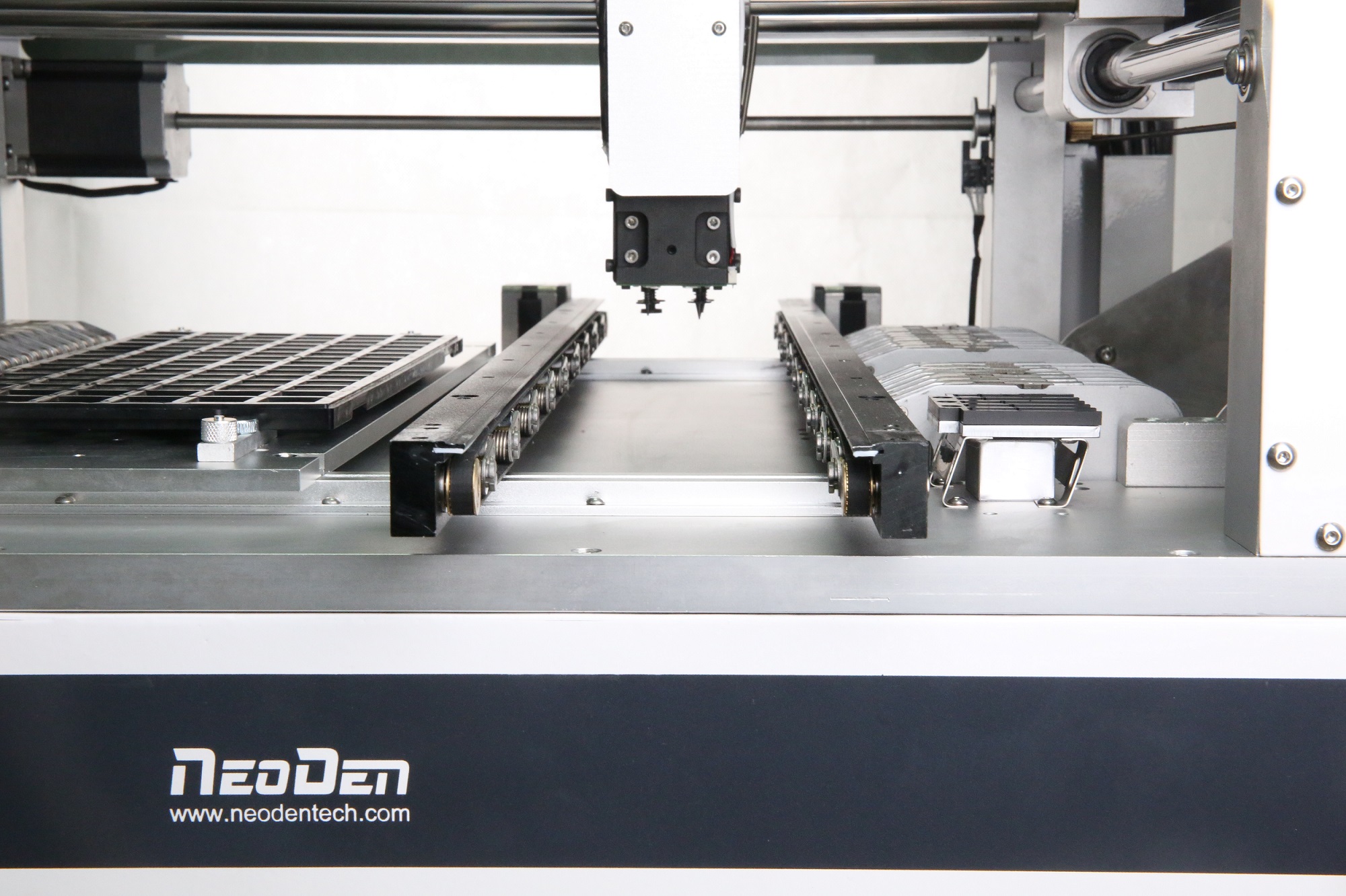

NeoDen Pick and place machine tabletop

Specifications

| Product name | NeoDen pick and place machine tabletop |

| Machine Style | Single gantry with 4 Heads |

| Placement Rate | 4000CPH |

| External Dimension | L 680×W 870×H 460mm |

| Max applicable PCB | 290mm*1200mm |

| Feeders | 48pcs |

| Average working power | 220V/160W |

| Component Range | Smallest Size: 0201 |

| Biggest Size: TQFP240 | |

| Max Height: 5mm |

Details

On-line dual rails

Neoden4 can support two different ways for PCB positioning, both seamless mounting via automatic rails and PCB self-positioning mounting. Both tube and tray package ICs can be supported at the same time.

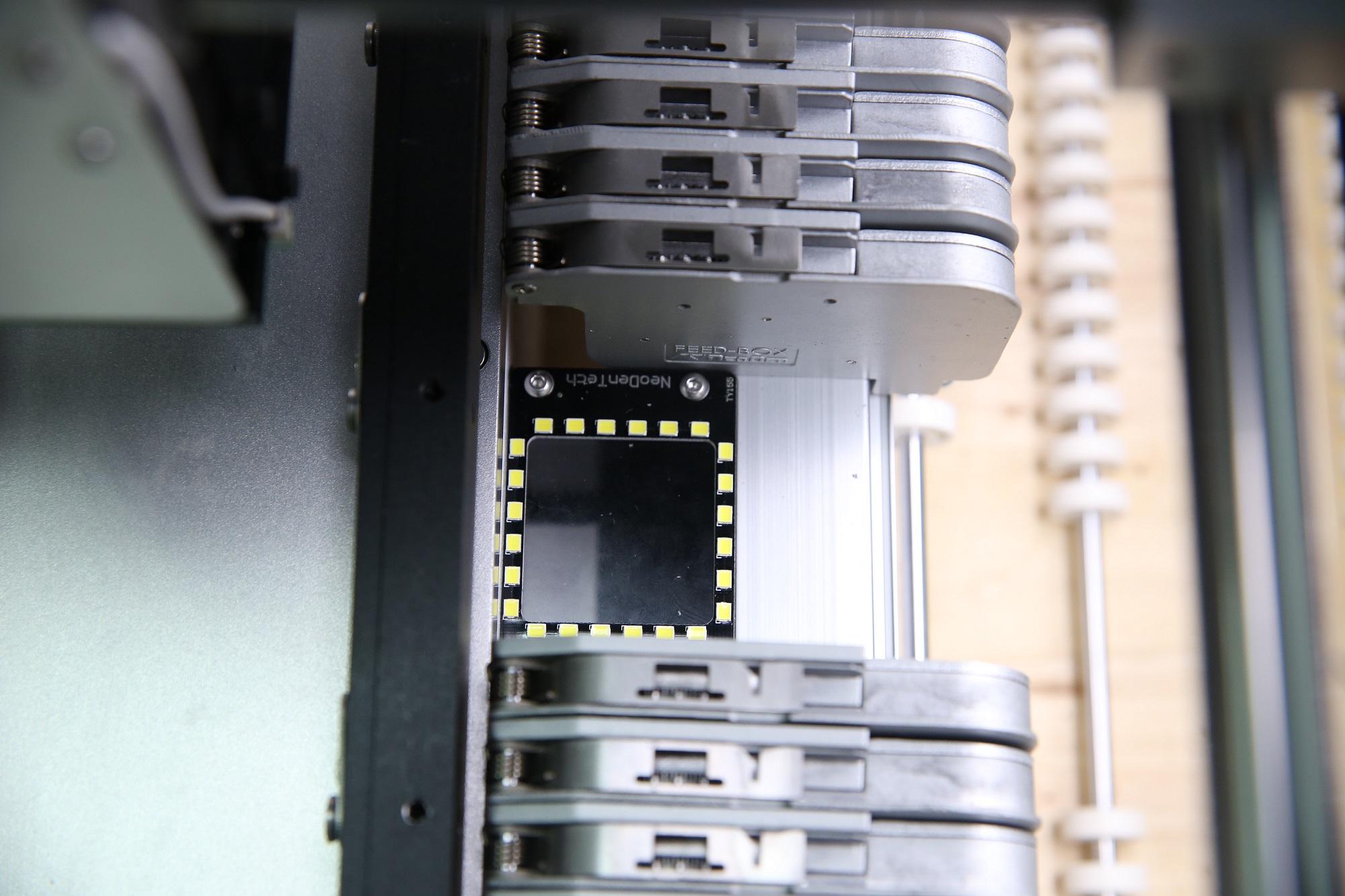

Vision system

The NeoDen4 features a high-precision, two-camera vision system. The cameras are made by Micron Technology and are precisely aligned to the nozzles using the single unified configuration/operation application that loads on power-on.

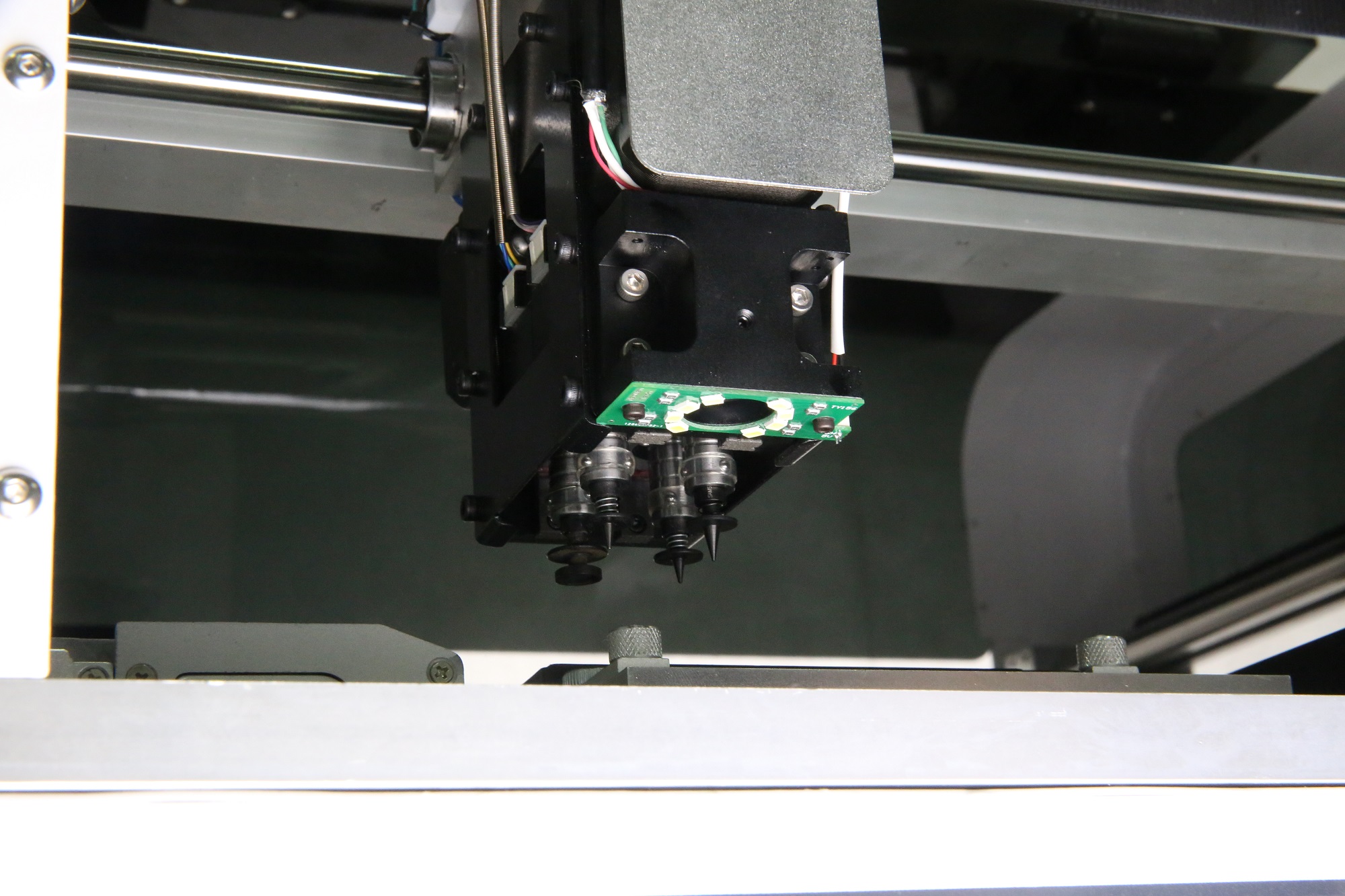

Four high precision nozzles

Any size nozzle can be installed in any of the four locations in the head, so a single machine can handle all of the necessary components without the need for nozzle changes. The spring-loaded nozzles simply snap in and pull out of the head. Any nozzle can be installed in any of the four locations on the head.

Electric tape-and-reel feeders

Electric tape-and-reel feeders, vibration feeders and virtual tray feeders are all supported. Because of the flexibility of the architecture, and the need to work with affordable quantities of parts, short tapes can also be configured on the machine’s bed.

Packing

Provide one-stop SMT assembly production line

Related products

|

|

|

| Automatic conveyor J12 | Reflow Oven IN6 |

If you need, please feel free to contact us.

FAQ

Q1: How can I buy machine from you?

A: (1) Consult us on line or by e-mail

(2) Negotiate and confirm the final price , shipping , payment method and other terms

(3) Send you the perfroma invoice and confirm your order

(4) Make the payment according to the method put on proforma nvoice

(5) We prepare your order in terms of the proforma invoice after confirming your full payment . And 100% quality check before shipping

(6) Send your order via express or by air or by sea.

Q2: MOQ?

A: 1 set machine, mixed order is also welcomed.

Q3: Can we customize the machine?

A: Of course. All of our machines can be customized.

Exhibition

Certificates

Factory

If you need, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

"Based on domestic market and expand abroad business" is our enhancement strategy for High Performance Pick And Place Automation - Pick and place machine tabletop for PCB macking – Neoden , The product will supply to all over the world, such as: Yemen, Cyprus, Angola, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality products. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our products and services, please do not hesitate to contact us!

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!