Good User Reputation for Led Pick And Place Robot - NeoDen K1830 pick and place automation machine – Neoden

Good User Reputation for Led Pick And Place Robot - NeoDen K1830 pick and place automation machine – Neoden Detail:

NeoDen K1830 pick and place automation machine video

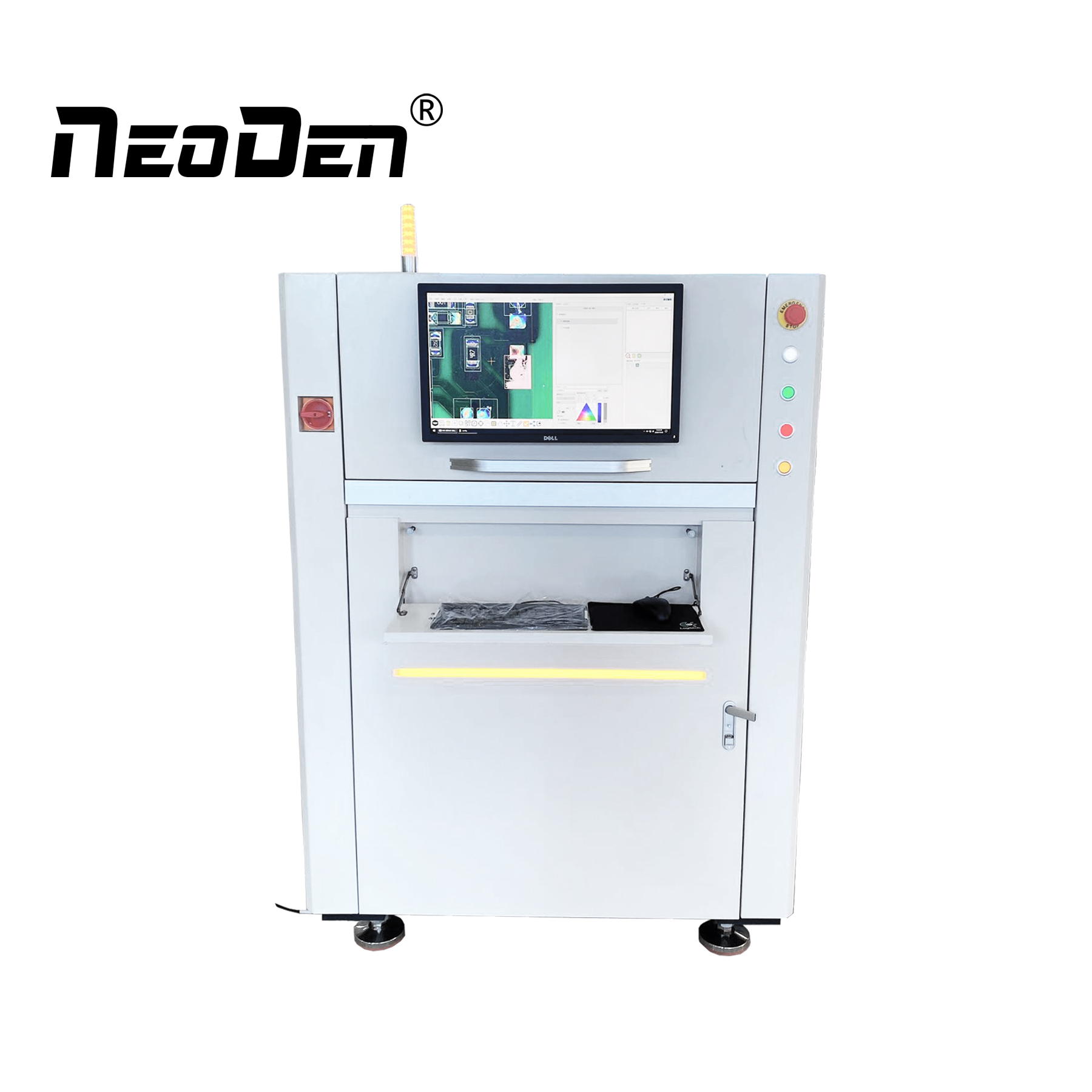

NeoDen K1830 pick and place automation machine

Description

| Product name | NeoDen K1830 pick and place automation machine |

| Nozzle Q’ty | 8 |

| Reel Tape Feeder Q’ty(Max) | 66 (Electric / Pneumatic) |

| IC Tray Feeder Q’ty | 10 (In Succession) |

| Max PCB size | 540*300mm(In Single Step) |

| Smallest Component Size | 0201(Electric Feeder Available) |

| IC Packages | QFP, SSOP, QFN, BGA |

| Placement accuracy | 0.01mm |

| Max Component Height | 18mm |

| Max Placement Speed | 16,000CPH |

| Component Recognition | High Resolution Flying Vision Camera System |

| PCB Fiducial Recognition | High Precision Mark Camera |

| PCB Loading | Synchronized 3 Stages Internal Conveyor system |

| PCB Transfer Direction | Left→Right |

| Air Supply | >0.6MPa |

| Power | 500W |

| Voltage | 220V/50HZ & 110V/60HZ |

| Net Weight | 280kgs |

| Gross Weight | 360kgs |

| Machine Dimensions | 1288×1062×1291mm(Without Tri-color Light) |

| Packing Dimensions | 1420×1220×1665mm |

Product Detail

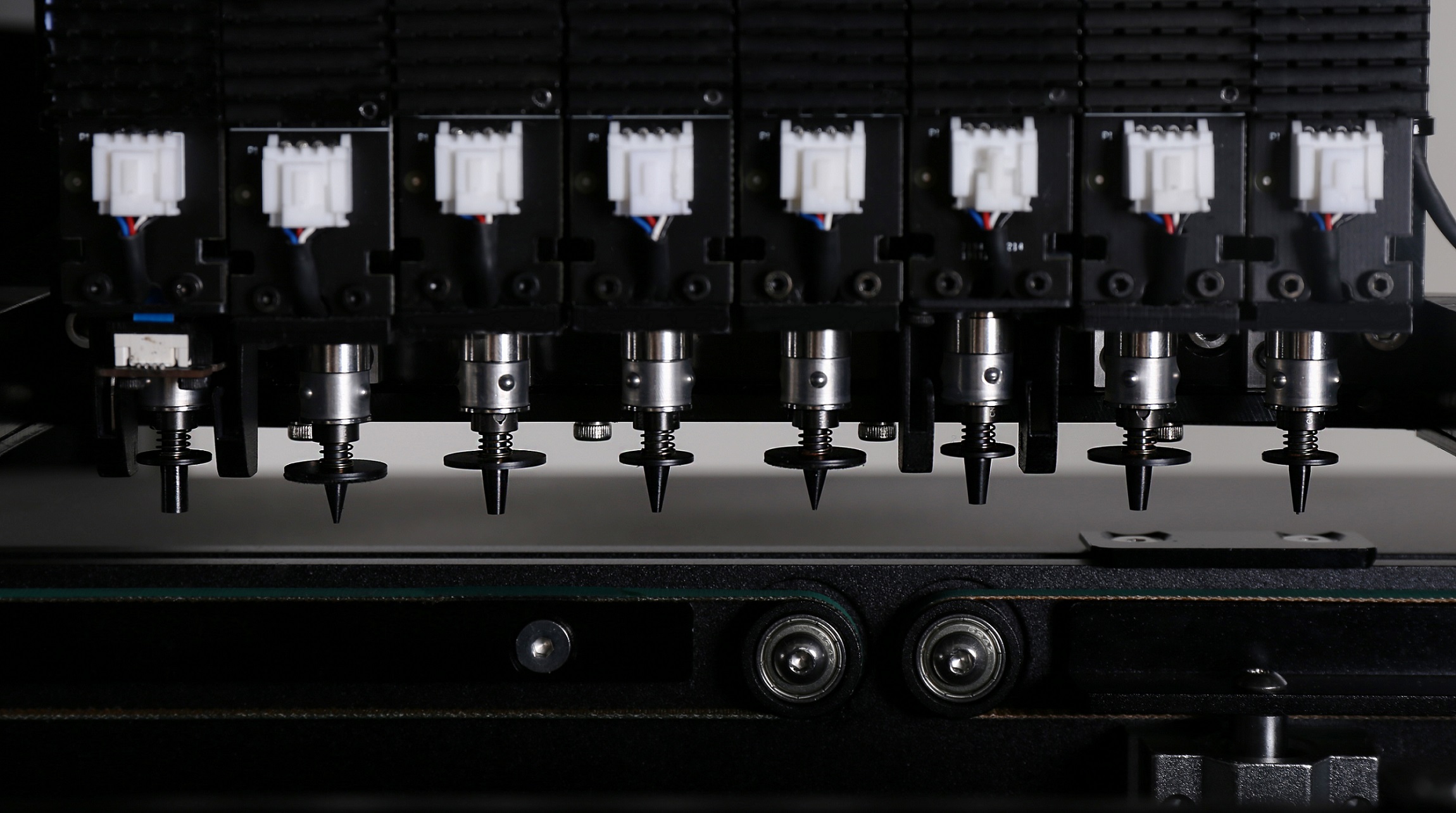

8 high speed nozzles

1-8 Synchronized Nozzles which ensure a repeatable placement accuracy with high speed.

2-Machine runs on highly stable and secure Linux operating system.

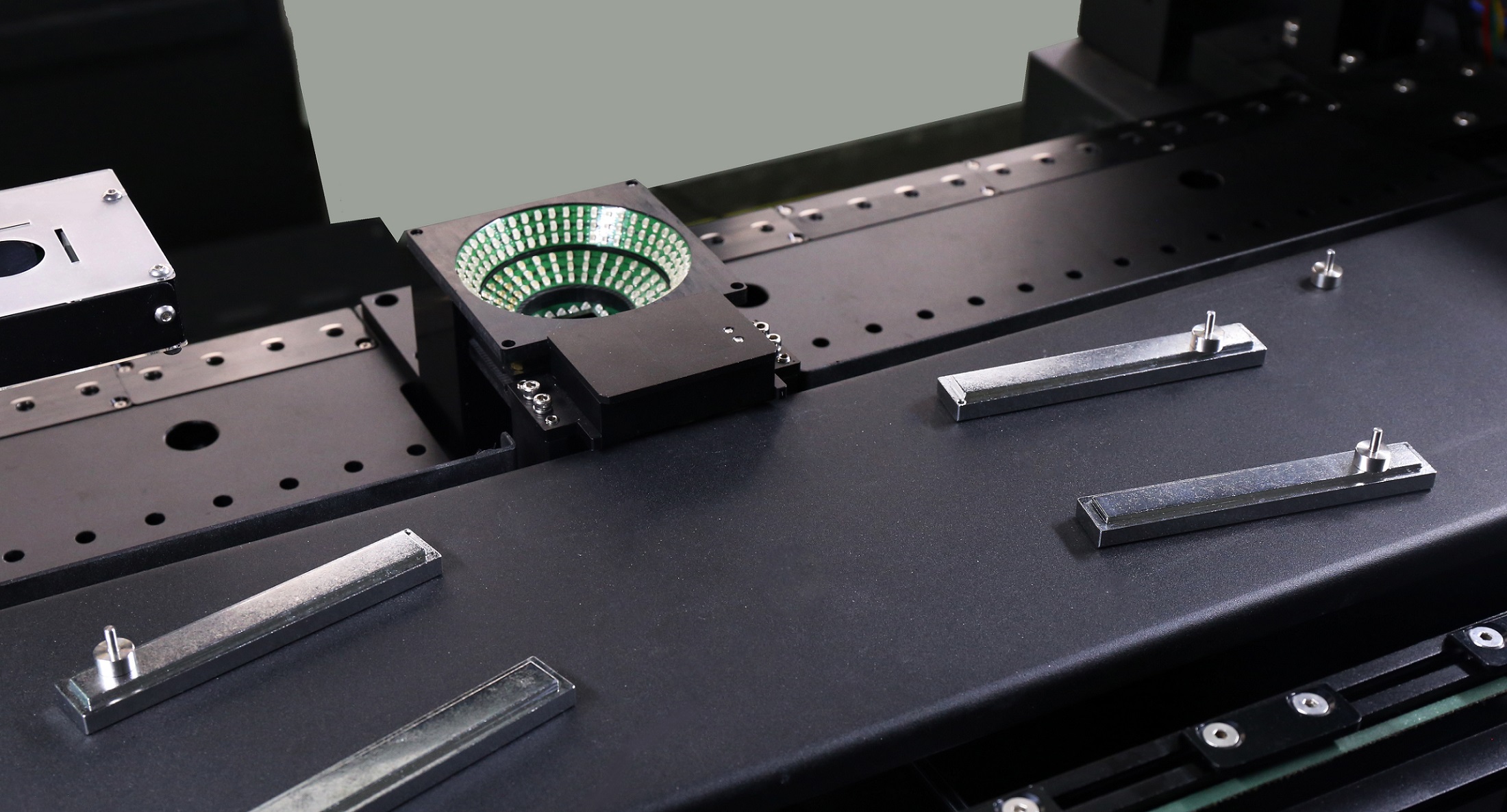

Vision system

1-Double mark cameras to reach at extreme end feeders for better calibration.

2-High resolution and high speed component camera system improves the overall speed of the machine.

66 Reel tape feeders

1-Closed loop Servo control system with feedback makes the machine to function more accurate.

2-Picking location of pneumatic feeder can be calibrated automatically and promptly,to ensure easy operation and high efficiency.

Feeder basic info

1. Skip: once selected, all components in this feeder will be skipped.

2. Feeder exchange: this function can be used if any reel tape was installed at wrong or inappropriate position. Select the feeder/ IC tray feeder you need to exchange, then the related feeder info will be synchronized to the swapped feeder/ IC tray feeder.

3. Place delay: For special components like large IC and large capacitor, it’s better to set some long time on the place delay to make sure nozzle can still suck the component stably during the movement to place on the board.

If you need, please don’t hesitate to send your inquiry.

Provide one-stop SMT assembly production line

Related Products

|

|

|

| Stencil printer FP2636 | Automatic conveyor J12 | Reflow Oven IN6 |

FAQ

Q1: Do you provide software updates?

A: Customers who buy our machine,we can offer free upgrades software for you.

Q2: This is the first time I use this kind of machine, is it easy to operate ?

A: We have English user manual and guide video to teach you how to use the machine . If still have question , pls contact us by email / skype / whatapp / phone / trademanager online service.

Q3: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

About us

Exhibition

Certification

Factory

If you need, please don’t hesitate to send your inquiry.

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we're the lowest around for Good User Reputation for Led Pick And Place Robot - NeoDen K1830 pick and place automation machine – Neoden , The product will supply to all over the world, such as: Cairo, Argentina, Uruguay, Welcome any of your inquiries and concerns for our products. We look forward to establishing a long-term business relationship with you in the near future. Contact us today. We are the first business partner for you!

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.