Good Quality NeoDen SMT Chip Mounter for LED Production Line

Our target should be to consolidate and enhance the top quality and service of current goods, in the meantime frequently create new products to satisfy diverse customers’ calls for for Good Quality NeoDen SMT Chip Mounter for LED Production Line, Influenced from the swift building marketplace of the quick food and beverage consumables all over the planet , We’re wanting forward to operating with partners/clients for making good results together.

Our target should be to consolidate and enhance the top quality and service of current goods, in the meantime frequently create new products to satisfy diverse customers’ calls for for China SMT Chip Mounter and Chip Mounter, Our market share of our goods has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, make sure you feel free to contact us. We’ve been looking forward to forming successful business relationships with new clients around the world in the near future. We are looking forward to your inquiry and order.

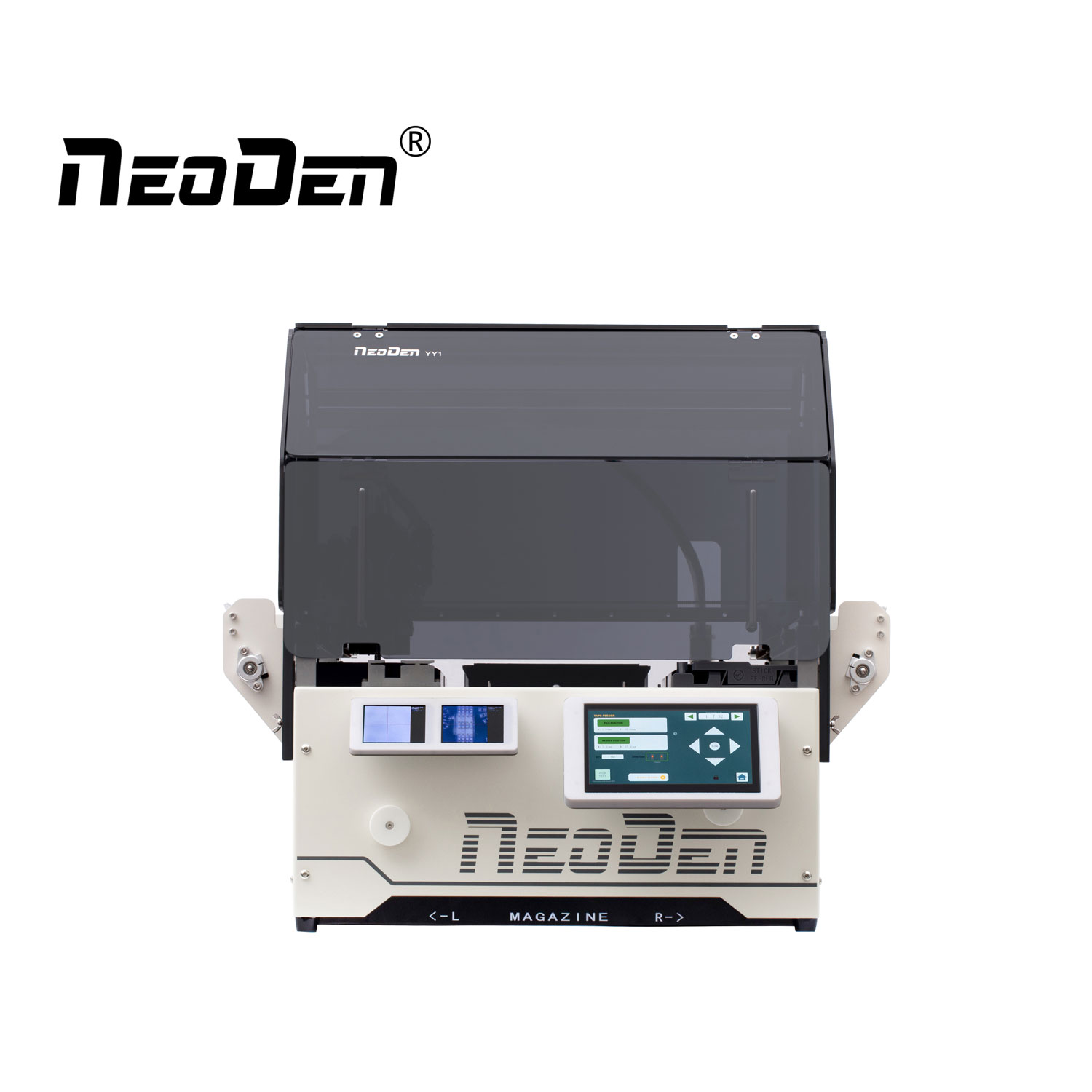

NeoDen YY1 Pick and Place Machine

Description

1. The newly-designed stick feeder with its compact shape, is perfectly compatible with the tape feeder system.

2. Supports bulk component feeder,strip feeder and IC tray feeder.

3. Newly designed software system & UI for visual programming and placement, which allows fast programming on the machine, friendly interface & easy operation.

4. Works in a near-perfect silent mode, making it a green and pollution-free pick and place machine.

5. Equipped with a vacuum detection function,can set standard vacuum detection values on placement head flexibly, all information can be displayed visually on the placement head.

Description

| Product name | NeoDen YY1 Pick and Place Machine | Placement Rate | Vision On: 3,000CPHVision Off: 4,000CPH |

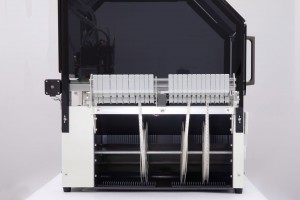

| Model | NeoDen YY1 | Feeder Capacity | Tape Feeder: 52 (all 8mm)Stick Feeder: 4

Flexible Feeder: 28 Bulk Feeder: 19 |

| Machine Style | Single Gantry With 2 Heads | Component Range | Smallest Size: 0201Largest Size: 18x18mm

Max Height: 12mm |

| Alignment | Vision & Vacuum | External Dimensions(mm) | Machine Size: 643(L)x530(W)x601(H)Packing Size: 700(L)x580(W)x585(H) (Wooden box) |

Product Detail

Vacuum Detection

Can set standard vacuum detection values on placement head flexibly,

all information can be displayed visually on the placement head.

Auto Nozzle Changer

It has 3 slots for nozzles replacement,

which realizes maximum optimum of nozzles and achieve higher continuity of production.

Dual vision system with built-in IC

Independent high-definition & high-speed dual vision recognition systems,

the speed of processing components’ photos becomes more efficient and accurate.

Powerful magazines

Easy to install and replace tape reels conveniently,

ensure the most excellence solution among all of the entry level machines with lower budget but higher stability.

User friendly touch screen

High-definition capacitive touch screen,

adjusted up and down to meet the needs of different viewing angles and enhance the user experiences.

Brand new patented peeling gadget

It’s simple but functional, it’s easy to install and flexible to remove.

Compared with the peelers of TM240A, it doesn’t need to collect wasted film.

Our Service

Provide product instructions

YouTube video tutorials

Experienced after-sales technicians, 24 hours online service

With our own manufactory and more than 10 years of experience in SMT industry

We can provide customers with the most cost-effective products.

About us

Factory

Certification

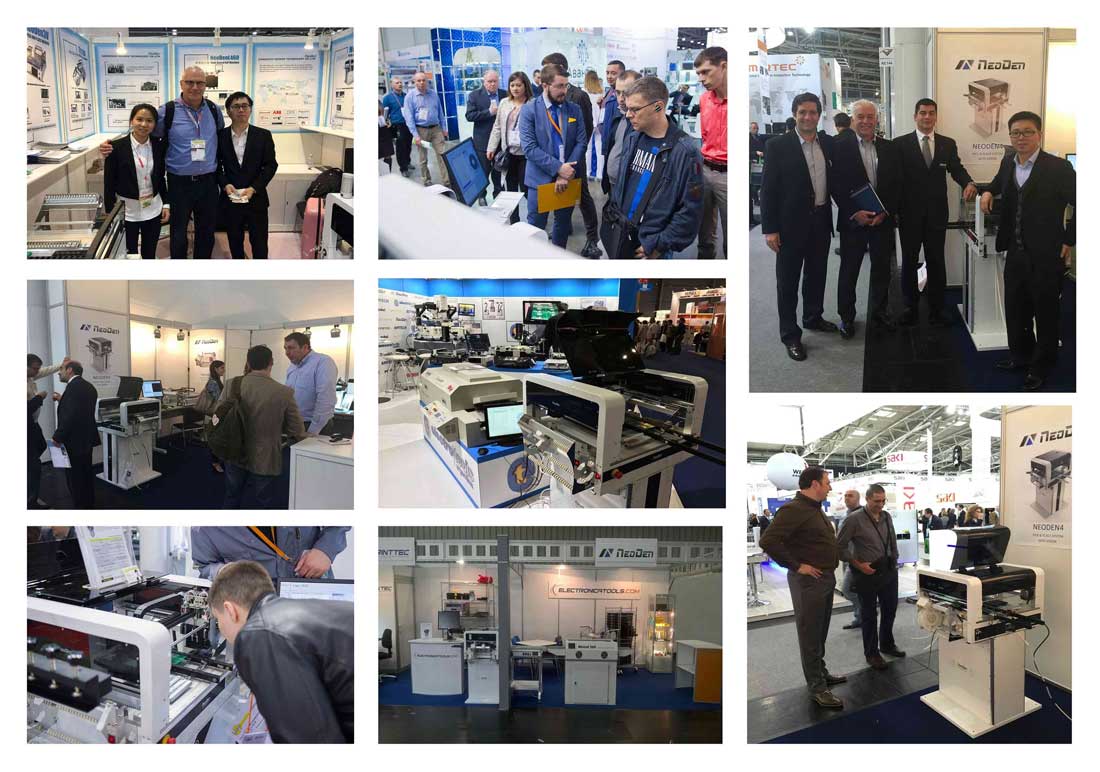

Exhibition

If you need, please feel free to contact us for more information.

FAQ

Q1: How can I place an order?

A: You can contact any of our sales person for an order.

Please provide the details of your requirements as clear as possible.

So we can send you the offer at the first time.

For designing or further discussion, it is better to contact us with Skype, TradeManger or QQ or WhatsApp or other instant ways, in case of any delays.

Q2: How far is your factory from the airport and train station?

A: From airport about 2 hours by car, and from train station about 30 minutes.

We can pick up you.

What Our Customers Say about YY1 SMT Machine?

.png)

“It’s actually much more intuitive to program and use.

The 3d printed parts are of very good quality and seem to have great layer adhesion.”

“We bought a Neoden4 when they were still pretty new and now also jumped on a YY1 as a backup machine.

YY1 arrived quickly and setup was pretty easy.

If you are looking for shorter feeder setup time and higher accuracy you have to invest quite a bit more. For prototyping the YY1 is the right choice and I’m sure we will have some fun with it.”

Our target should be to consolidate and enhance the top quality and service of current goods, in the meantime frequently create new products to satisfy diverse customers’ calls for for Good Quality NeoDen SMT Chip Mounter for LED Production Line. We’re wanting forward to operating with partners/clients for making good results together.

Good Quality China SMT Chip Mounter and Chip Mounter, Our market share of our goods has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, make sure you feel free to contact us. We’ve been looking forward to forming successful business relationships with new clients around the world in the near future. We are looking forward to your inquiry and order.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.