Full Automatic BGA Rework Station

Full Automatic BGA Rework Station

Specification

Product name: Full Automatic BGA Rework Station

Power Supply: AC220V±10% 50/60HZ

Power: 5.65KW(Max), Top heater (1.45KW)

Bottom heater (1.2KW), IR Preheater (2.7KW), Other (0.3KW)

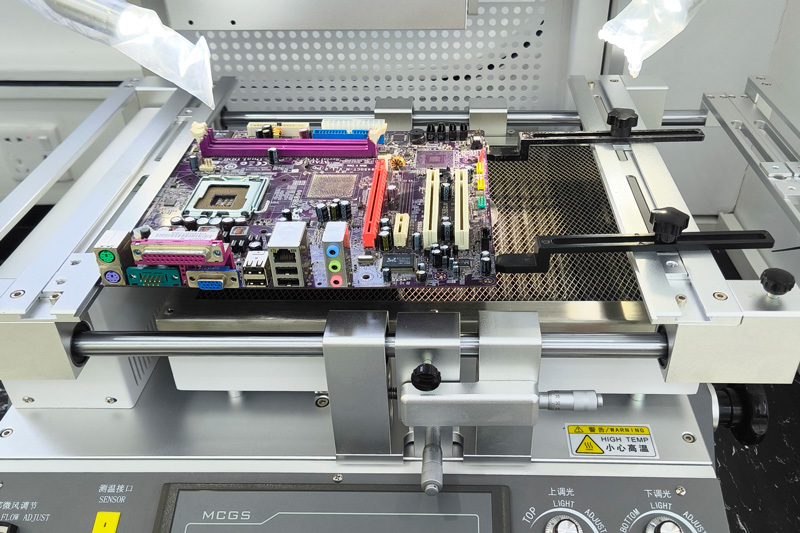

PCB Size: 412*370mm(Max); 6*6mm(Min)

BGA Chip Size: 60*60mm(Max); 2*2mm(Min)

IR Heater Size: 285*375mm

Temperature Sensor: 1 pcs

Operation Method: 7" HD touch screen

Alignment Accuracy: ±0.02mm

Dimensions: L685*W633*H850mm

Weight: 76KG

Detail

IR Heating Area

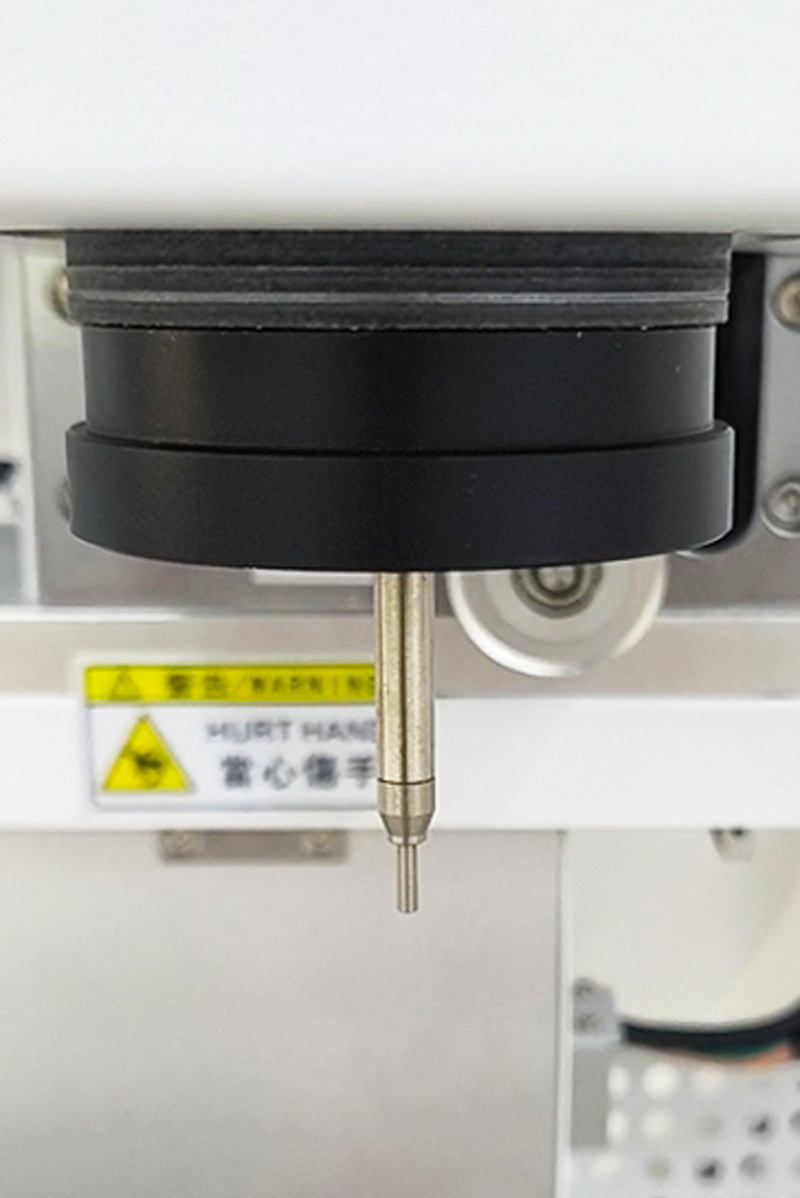

Suction Nozzle

PCB Fixation Platform

IR Laser

Display

Sensor

Provide one-stop SMT assembly production line

FAQ

Q1: How can I buy machine from you?

A: (1) Consult us on line or by e-mail.

(2) Negotiate and confirm the final price, shipping, payment method and other terms.

(3) Send you the perfroma invoice and confirm your order.

(4) Make the payment according to the method put on proforma nvoice.

(5) We prepare your order in terms of the proforma invoice after confirming your full payment. And 100% quality check before shipping

(6) Send your order via express or by air or by sea.

Q2: MOQ?

A: 1 set machine, mixed order is also welcomed.

Q3: Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

About Us

Exhibition

Certification

Our Factory

Established in 2010 with 100+ employees & 8000+ Sq.m. factory of independent property rights, to ensure the standard management and achieve the most economic effects as well as saving the cost.

Owned the own machining center, skilled assembler, tester and QC engineers, to ensure the strong abilities for NeoDen machines manufacturing, quality and delivery.

NeoDen supplies life-long technical support and service for all of the NeoDen machines, moreover, regular software updates based on the using experiences and actual daily request from the endusers.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.