Featured Products

-

Chinese Professional China Manufacturer of SMT Automatic Solder Printing Machine Stencil Printer

Automatic SMT paste printer good identification, suitable for tinning, copper plating, Gold plating, tin spraying, FPC and other types of PCB with different colors.

-

Easy to Operate Lead-Free Wave Soldering Machine

ND200 wave soldering machine use hot wind heating method.

mitsubishi PLC+ touch screen machine control.

Axial fan cooling method.

-

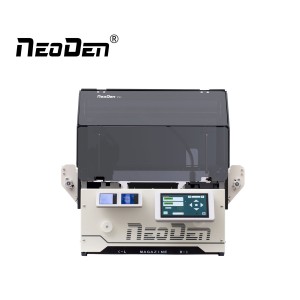

Neoden K1830 PCB Component Mounting Machine, SMT Pick and Place Machine

NeoDen K1830 SMT automatic pick and place machine runs on highly stable, double mark cameras to reach at extreme end feeders for better calibration.

-

Cheapest Factory Hot Sale SMT Production Line Visual Pick and Place Machine

NeoDen YY1 pick and place machine newly-designed stick feeder with its compact shape, is perfectly compatible with the tape feeder system.

Supports bulk component feeder, strip feeder and IC tray feeder.

-

PCB Assembling SMT Machine Hot Air Reflow Oven with Best Price

NeoDen IN12 reflow oven for PCB welding lightweight, miniaturization, professional industrial design, flexible application site, more user-friendly.

-

Original Factory High Speed Low Cost SMT Pick and Place Production Line Machines

NeoDen9 pick and place machine independent control of 6 placement heads, each head can be up and down separately, and the standard effective mounting height reach 16mm.

-

NeoDen YY1 PNP Machine for SMT Production Line

NeoDen YY1 pick and place machine newly-designed stick feeder with its compact shape, is perfectly compatible with the tape feeder system.

Supports bulk component feeder, strip feeder and IC tray feeder.

-

Factory supplied SMT Full Automatic Assembly Production Line LED Reflow Oven

NeoDen IN12C SMT reflow oven has 12 temperature zones compact design, lightweight and compact; to achieve intelligent temperature control, with high-sensitivity temperature sensor, with stable temperature in the furnace, the characteristics of small horizontal temperature difference.

-

China wholesale SMD PCB Assembly Screen Printer SMT Solder Paste Printer

Full automatic visual printer camera system individual camera, up or down individual imaging vision system, geometrical matching positioning.

Print mode Single or Twin scraper print.

-

Reasonable price NeoDen SMT Line Placement Equipment Pick and Place Machine

NeoDen YY1 pick and place machine newly-designed stick feeder with its compact shape, is perfectly compatible with the tape feeder system.

Supports bulk component feeder, strip feeder and IC tray feeder.

-

PriceList for SMT Line Lead Free Reflow Soldering Wave Soldering Machine

ND200 wave soldering machine use hot wind heating method.

mitsubishi PLC+ touch screen machine control.

Axial fan cooling method.

-

Good Wholesale 2 Heads LED Chip Mounter Machine SMT Pick and Place Machine

NeoDen YY1 pick and place machine newly-designed stick feeder with its compact shape, is perfectly compatible with the tape feeder system.

Supports bulk component feeder, strip feeder and IC tray feeder.