Featured Products

-

Nozzle

Although nozzles are small spare parts in SMT machines, without high-quality nozzles, SMT equipment is unable to pick and place components accurately and run efficiently.

Neoden is a reliable manufacturer with 10 years experience, we pride ourselves in the ability to provide customers with high-quality products and excellent after-sale service.

All products are NEW and in good condition, therefore they are a direct replacement for your old parts. The nozzles are made of long-life ceramic material, and suitable for Neoden pick and place machines.

-

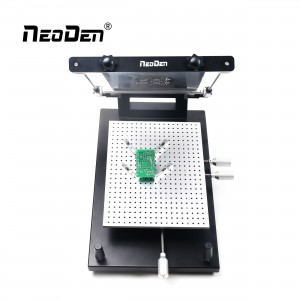

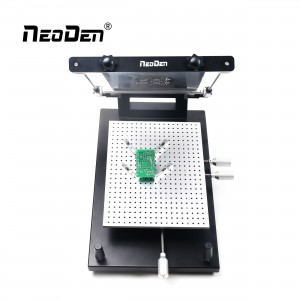

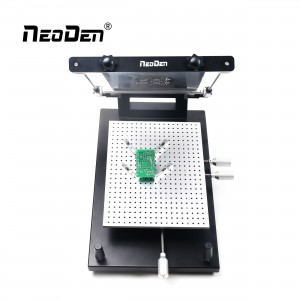

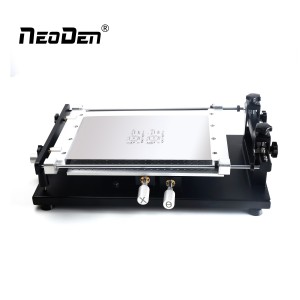

Paste printer

Paste printer NeoDen FP2636 has adjustable rubber footing, ensure the flatness while operating.

L supports and pins to fix PCB, applicable for multiple types PCBs’fixation and printing, more flexible and convenient.

-

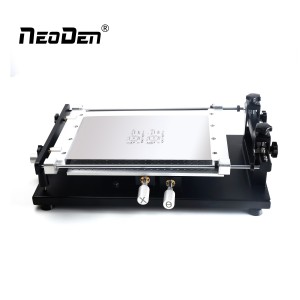

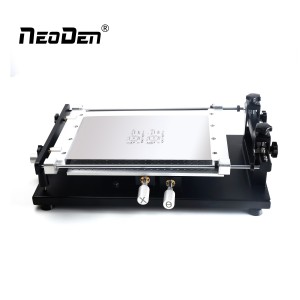

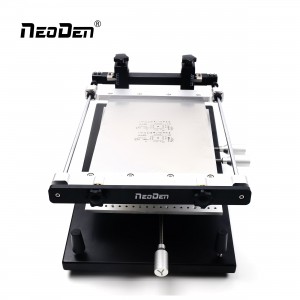

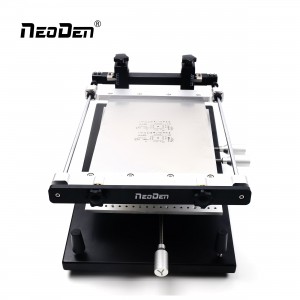

Manual PCB Printer

Manual PCB Printer NeoDen FP2636 has letter mark for each regulating handle, better and easier to operate.

-

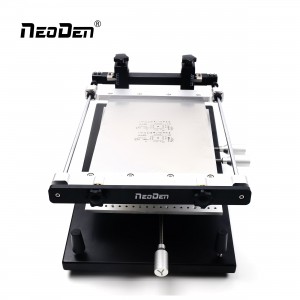

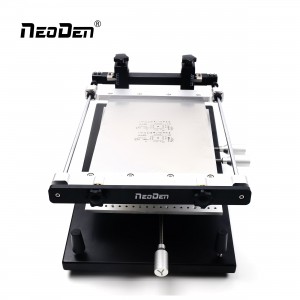

Manual Screen Printers NeoDen FP2636

Manual screen printers NeoDen FP2636 has L supports and pins to fix PCB, applicable for multiple types PCBs’ fixation and printing, more flexible and convenient.

-

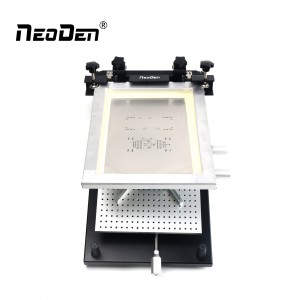

Manual Screen Printer

Manual Screen Printer NeoDen FP2636 has straight damping shaft, ensure the stencil fixed frame can be fastened at random angles, to improve convenience while operating.

-

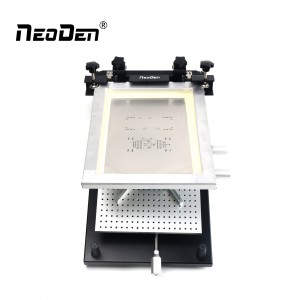

Frameless stencil printer

Frameless printer NeoDen FP2636 has the mechanical fixation frame for quick installation and replacement of frameless stencils, ensure high-efficiency but low-cost.

-

Manual frameless stencil printer

Manual frameless stencil printer NeoDen FP2636 has adjustable rubber footing,ensure the flatness while operating.

-

Frameless Printer

Frameless printer NeoDen FP2636 use adjustable rubber footing, ensure the flatness while operating. Letter mark for each regulating handle, better and easier to operate.

-

Frame Less stencil printer

Frame Less stencil printer use adjustable rubber footing, ensure the flatness while operating. Letter mark for each regulating handle,better and easier to operate.

-

LED SMD Printer

LED SMD Printer NeoDen FP2636 has letter mark for each regulating handle, better and easier to operate. Rulers of stencil fixed frame for reference lines,ensure the levelness between stencil and PCB.

-

High precision stencil printer

High precision stencil printer NeoDen FP2636 has letter mark for each regulating handle, better and easier to operate. Rulers of stencil fixed frame for reference lines,ensure the levelness between stencil and PCB.

-

SMT reflow soldering equipment reflow oven

NeoDen IN6 SMT reflow soldering equipment reflow oven has full convection, excellent soldering performance.