Featured Products

-

NeoDen Automatic Storage Machine

NeoDen automatic storage machine is controlled by PLC system and has stable working performance. The interface of touch screen is convenient and beautiful.

-

NeoDen IN6 PCB soldering reflow oven machine

NeoDen IN6 PCB soldering reflow oven machine’s PCB soldering temperature curve can be displayed based on real-time measurement.

-

NeoDen LED reflow soldering machine

LED reflow soldering machine’s PCB soldering temperature curve can be displayed based on real-time measurement.

-

NeoDen hot air reflow oven|reflow station

NeoDen hot air reflow oven|reflow station’s PCB soldering temperature curve can be displayed based on real-time measurement.

-

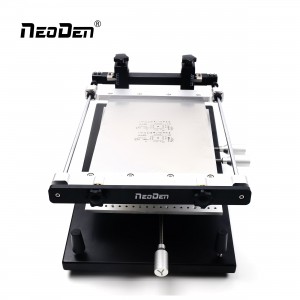

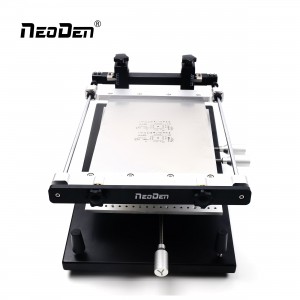

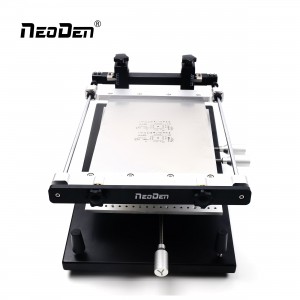

Manual SMT solder paste printer stencil printer

Manual SMT solder paste printer straight damping shaft, ensure the stencil fixed frame can be fastened at random angles, to improve convenience while operating.

-

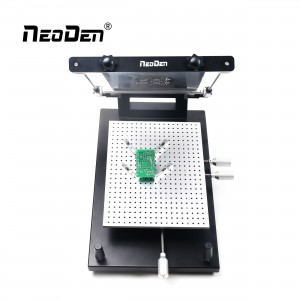

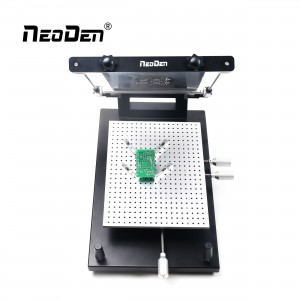

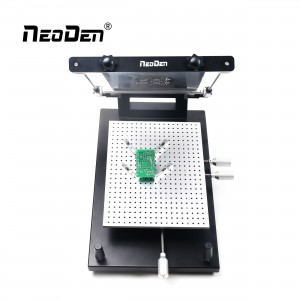

NeoDen PCB machine printer|screen printing machine

PCB machine printer support for single sided as well as double sided PCB and Letter mark for each regulating handle, better and easier to operate.

-

NeoDen manual SMT solder paste printer|SMT stencil printer

NeoDen manual SMT solder paste printer’s mechanical fixation frame for quick installation and replacement of frameless stencils, ensure high-efficiency but low-cost.

-

SMT stencil printer machine solder paste stencil printer

Solder paste stencil printer straight damping shaft, ensure the stencil fixed frame can be fastened at random angles, to improve convenience while operating.

-

Manual SMD PCB frameless solder printer

Manual frameless solder printer straight damping shaft, ensure the stencil fixed frame can be fastened at random angles, to improve convenience while operating.

-

NeoDen K1830 PNP machine pick and place LED machine

NeoDen K1830 PNP machine pick and place LED machine PCB location can be calibrated automatically and promptly, based on the correct and specific placement request.

-

NeoDen K1830 high speed Pick and Place PCB Machine

NeoDen K1830 high speed pick and place has 8 synchronized nozzles which ensure a repeatable placement accuracy with high speed.

-

NeoDen K1830 LED Pick and Place Robot Machine with Vision

NeoDen K1830 LED Pick and Place Robot Machine with Vision has 8 synchronized nozzles which ensure a repeatable placement accuracy with high speed.