Factory wholesale Reflow Soldering Oven - NeoDen IN12C SMT Reflow Oven – Neoden

Factory wholesale Reflow Soldering Oven - NeoDen IN12C SMT Reflow Oven – Neoden Detail:

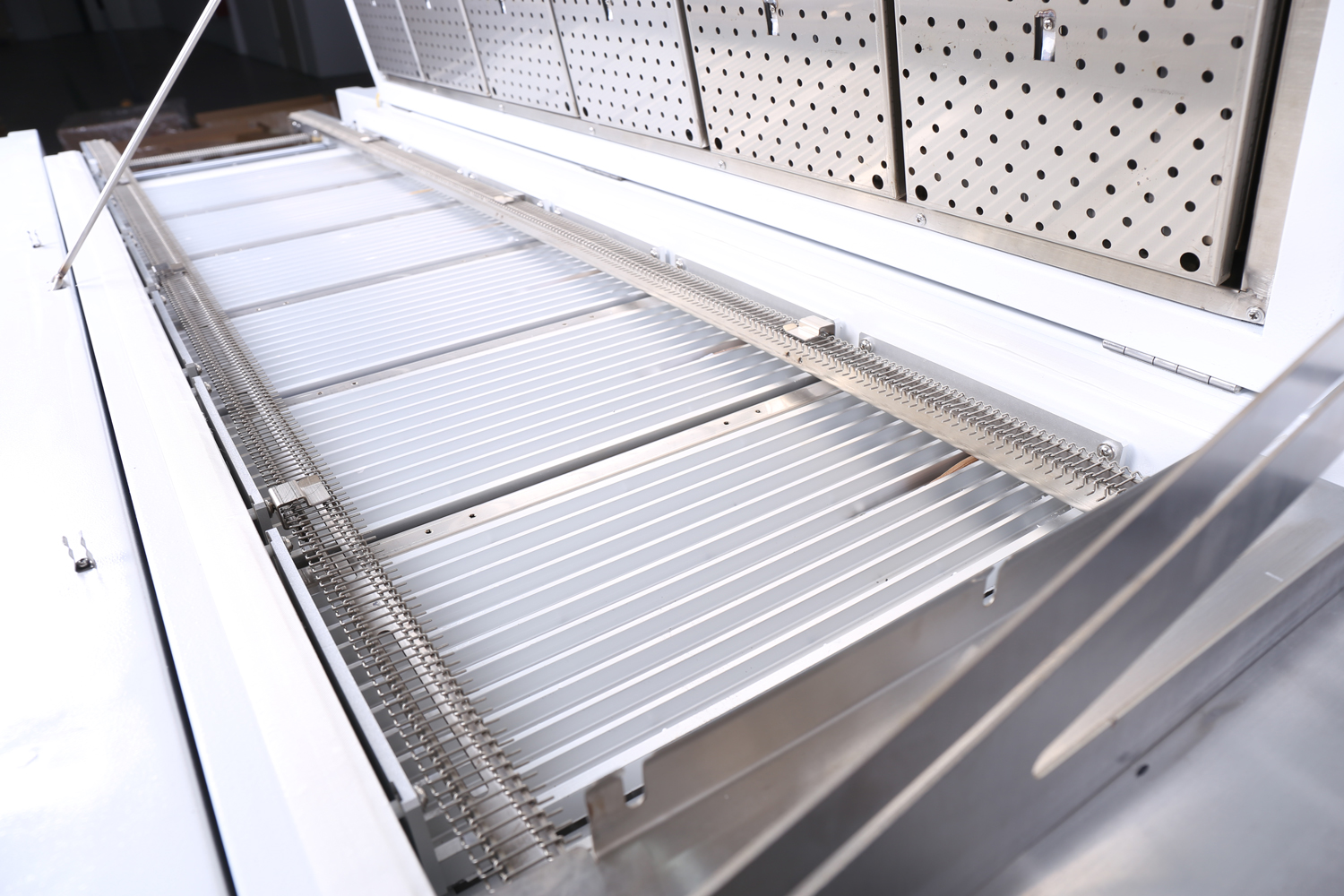

NeoDen IN12C SMT Reflow Oven

Specification

| Product name | NeoDen IN12C SMT Reflow Oven |

| Model | NeoDen IN12C |

| Heating Zone Quantity | Upper6 / Down6 |

| Cooling Fan | Upper4 |

| Conveyor Speed | 50~600 mm/min |

| Temperature Range | Room temperature~300℃ |

| Temperature Accuracy | 1℃ |

| PCB Temperature Deviation | ±2℃ |

| Max soldering height(mm) | 35mm (includes PCB thickness) |

| Max Soldering Width (PCB Width) | 350mm |

| Length Process Chamber | 1354mm |

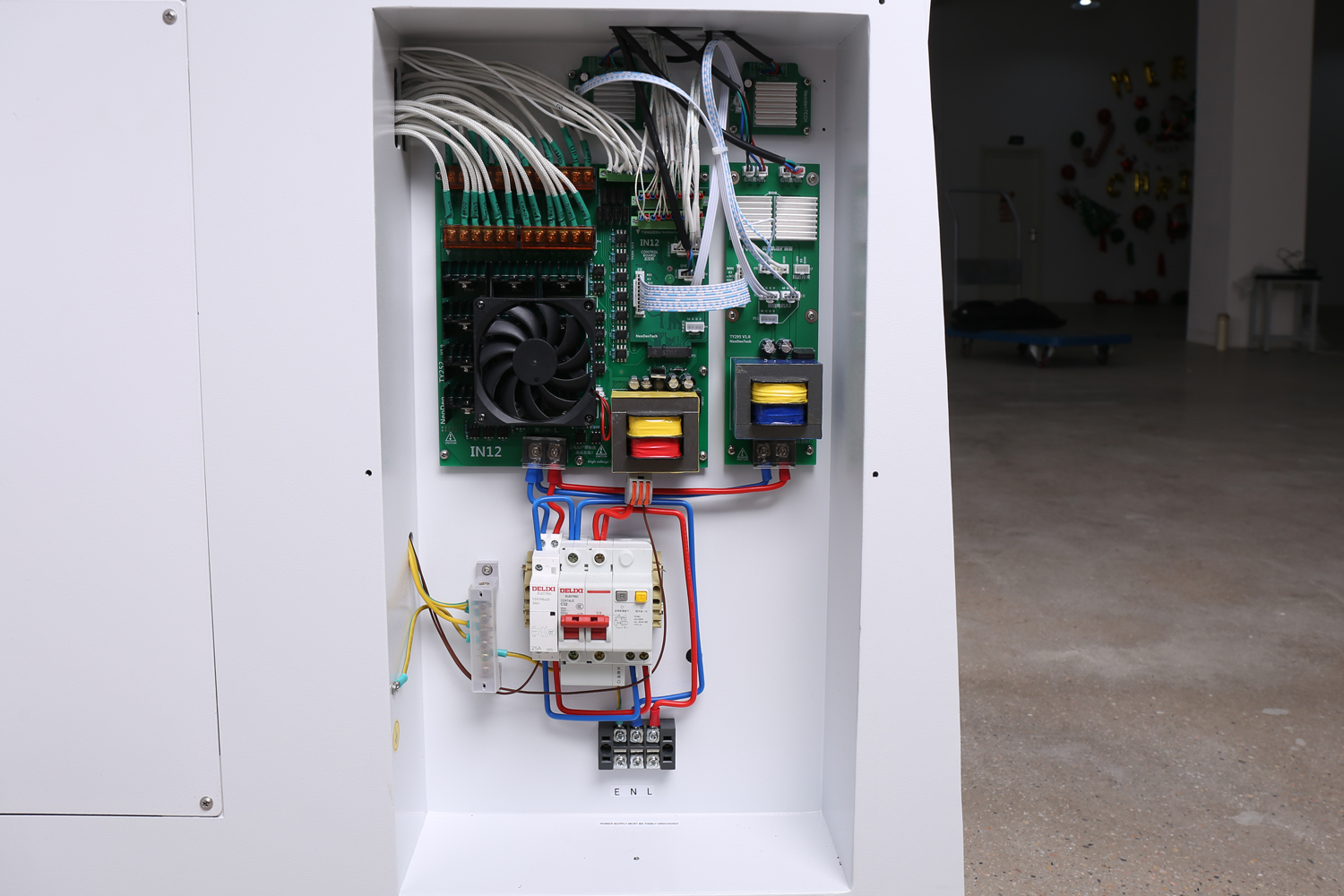

| Electricity Supply | AC 220v/single phase |

| Machine Size | L2305mm×W612mm×H1230mm |

| Heat-up Time | 30 min |

| Net Weight | 300Kgs |

Details

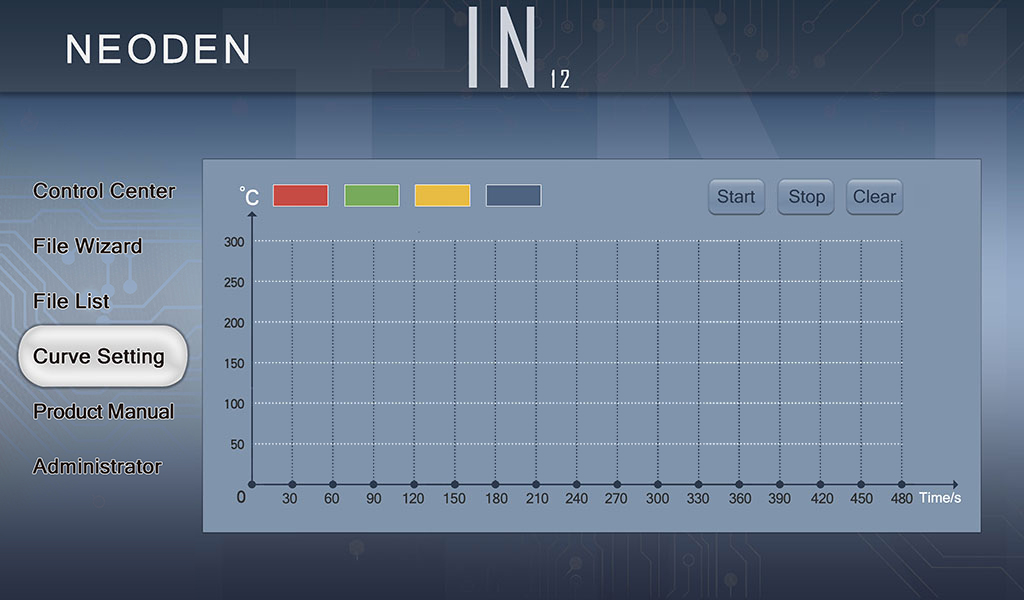

Real-time measurement

1- PCB soldering temperature curve can be displayed based on real-time measurement.

2- Professional and unique 4-way board surface temperature monitoring system, can give timely and comprehensive data feedback in actual operation.

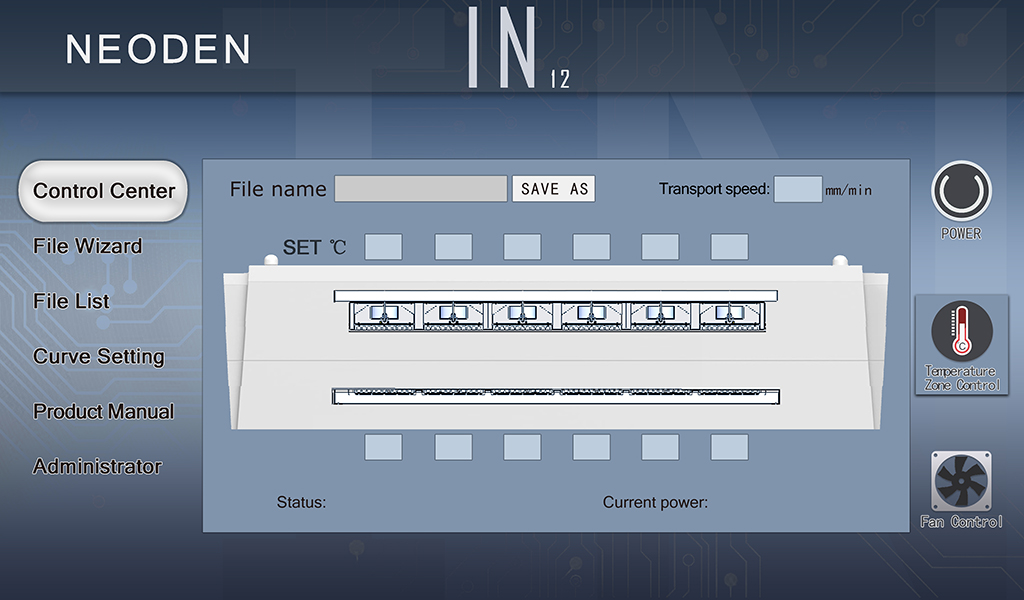

Intelligent control system

1-Heat insulation protection design, the casing temperature can be effectively controlled.

2- Smart control with high sensitivity temperature sensor, the temperature can be effectively stabilized.

3-Intelligent, the custom developed intelligent control system, easy to use and powerful.

Energy saving & Eco-friendly

1-Built-in welding smoke filtering system, effective filtration of harmful gases.

2-Energy saving, low power consumption, low power supply requirements, the ordinary civil electricity can meet the use.

3-The internal thermostat is made of stainless steel, which is environment friendly and has no peculiar smell.

Attentive design

1-Hidden screen design is convenient for transportation, easy to use.

2-The upper temperature cover is automatically limited once opened, effectively ensuring the personal safety for the operators.

Our Service

1. More Professional service in PNP machine field

2. Better manufacture ability

3. Various payment term to choose: T/T, Western Union, L/C, Paypal

4. High quality/Safe material/Competitive price

5. Small order available

6. Quickly response

7. More safe and fast transport

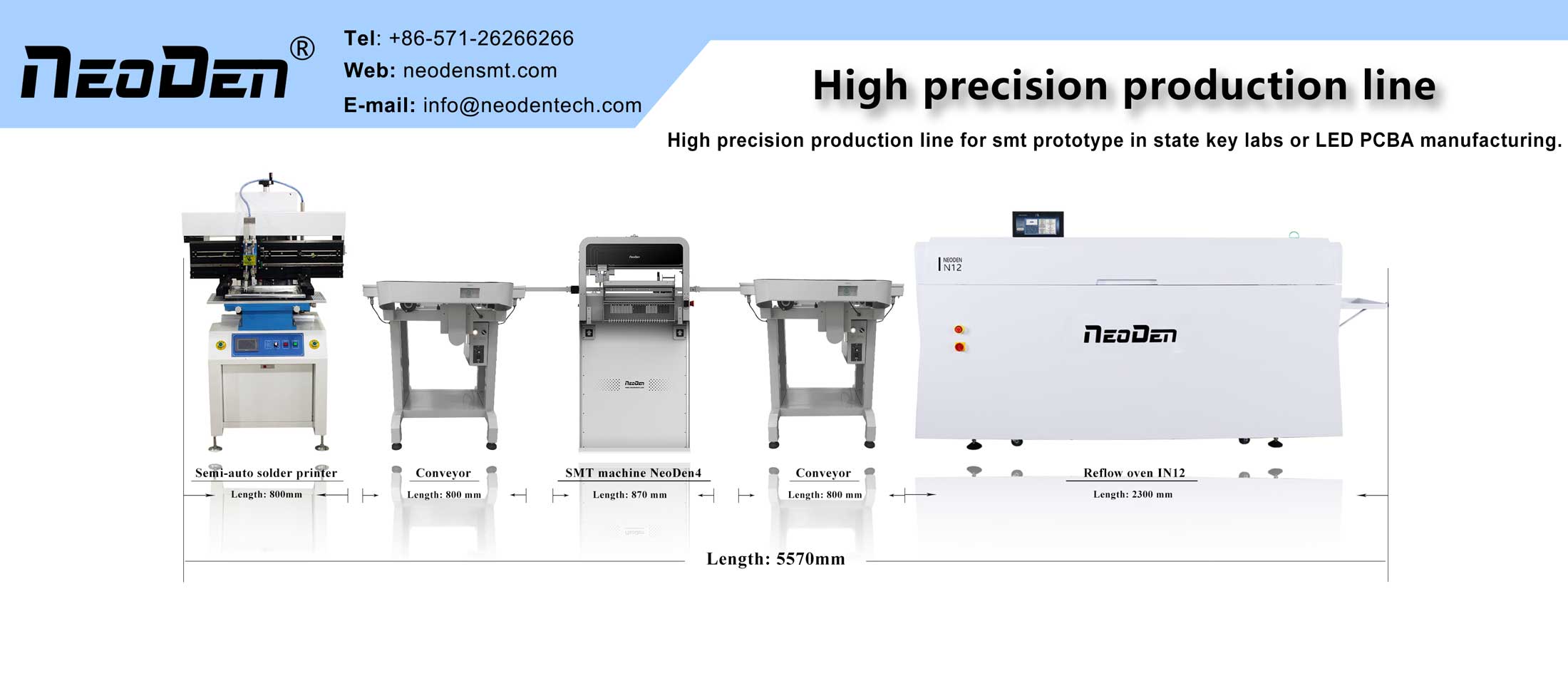

Provide one-stop SMT assembly production line

Related products

|

|

|

|

| Stencil printer FP2636 | SMT machine NeoDen K1830 | Pick and place machine NeoDen4 | AOI machine |

FAQ

Q1: How long is your delivery time?

A: The general delivery time is 15-30 days after receiving your order confirmation. Anther, if we have the goods in stock, it will only take 1-2 days.

Q2: What about the lead time for mass production?

A: Honestly, it depends on the order quantity and the season you place the order.

Alway 15-30 days based on general order .

Q3: Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

About us

Factory

Exhibition

Certification

If you need, please feel free to contact us for more information.

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for Factory wholesale Reflow Soldering Oven - NeoDen IN12C SMT Reflow Oven – Neoden , The product will supply to all over the world, such as: Argentina, Montpellier, Cancun, Our company adheres to the spirit of "lower costs, higher quality, and making more benefits for our clients". Employing talents from the same line and adhering to the principle of "honesty, good faith, real thing and sincerity", our company hopes to gain common development with clients from both at home and abroad!

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.