factory Outlets for Desktop Pick And Place Robot - SMT Pick and Place Machine Line SMT chip mounter – Neoden

factory Outlets for Desktop Pick And Place Robot - SMT Pick and Place Machine Line SMT chip mounter – Neoden Detail:

SMT Pick and Place Machine Line Video

NeoDen4 SMT Pick and Place Machine Line

Specifications

| Product name | NeoDen4 SMT Pick and Place Machine Line |

| Machine Style | Single gantry with 4 Heads |

| Placement Rate | 4000CPH |

| External Dimension | L 680×W 870×H 460mm |

| Max applicable PCB | 290mm*1200mm |

| Feeders | 48pcs |

| Average working power | 220V/160W |

| Component Range | Smallest Size: 0201 |

| Biggest Size: TQFP240 | |

| Max Height: 5mm |

Details

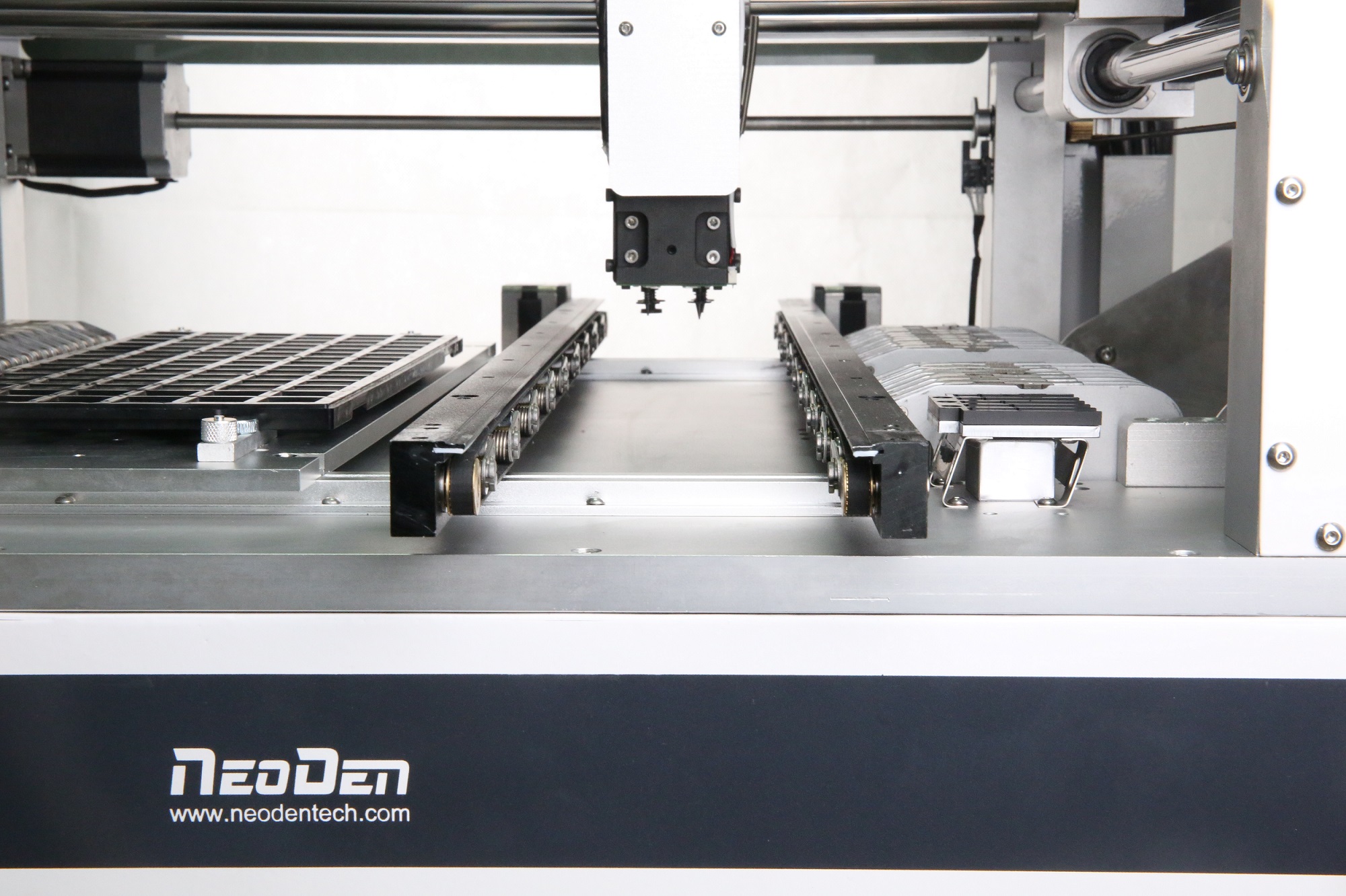

On-line dual rails

Machines equipped with the auto-loading rail system can accommodate boards from to in width, and in length.

Even when the rail system is installed, any space left over on the table is still available for trays and short tapes.

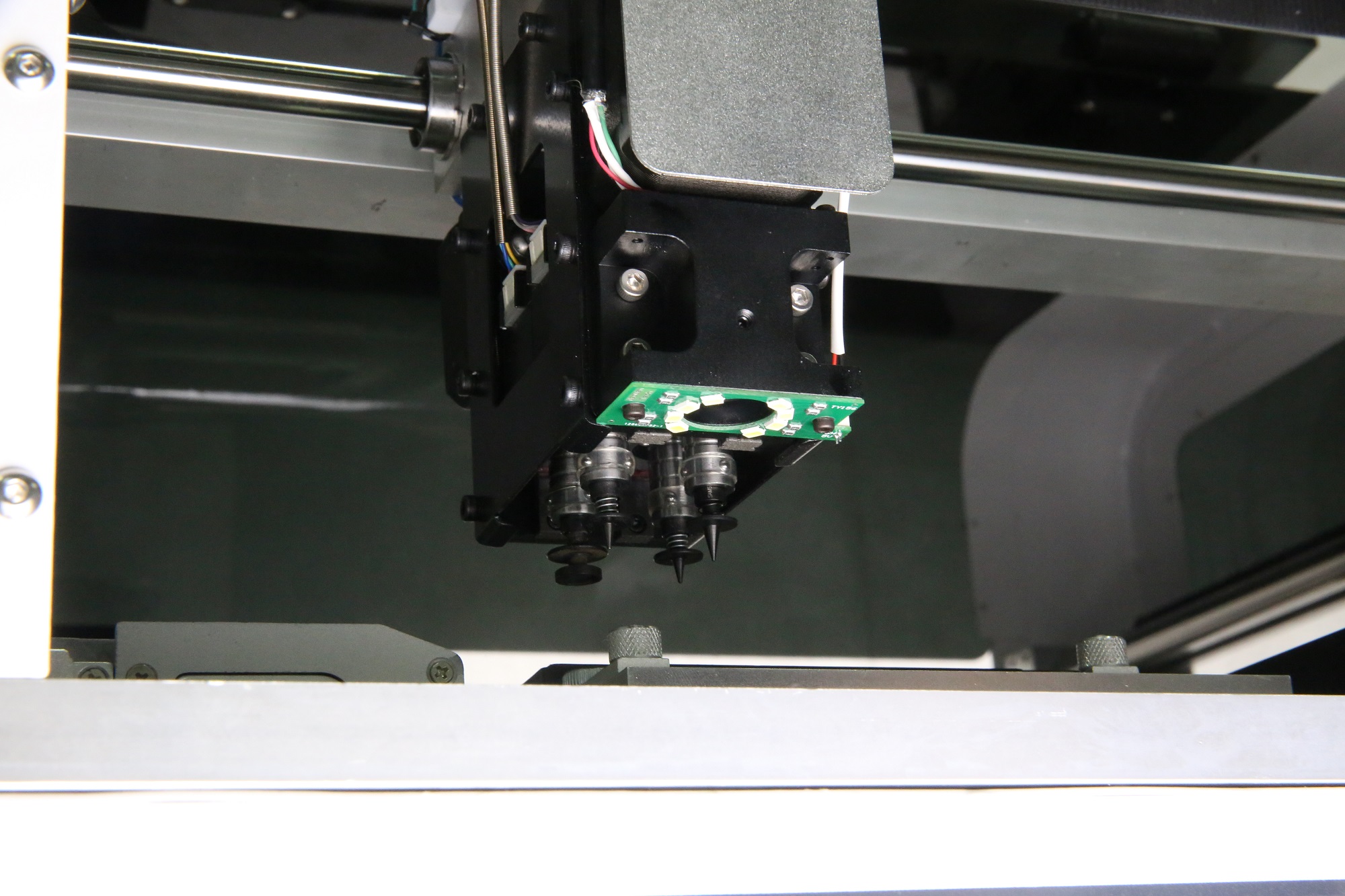

Vision system

Installed with high speed industry CCD cameras, and work with our patented image distortion processing algorithms, enable cameras can recognize and align different components of four nozzles. With the help of upper-camera and down looking camera, they will display the picking process with high definition image.

Four high precision nozzles

Electric tape-and-reel feeders, vibration feeders and virtual tray feeders are all supported. Because of the flexibility of the architecture, and the need to work with affordable quantities of parts, short tapes can also be configured on the machine’s bed.

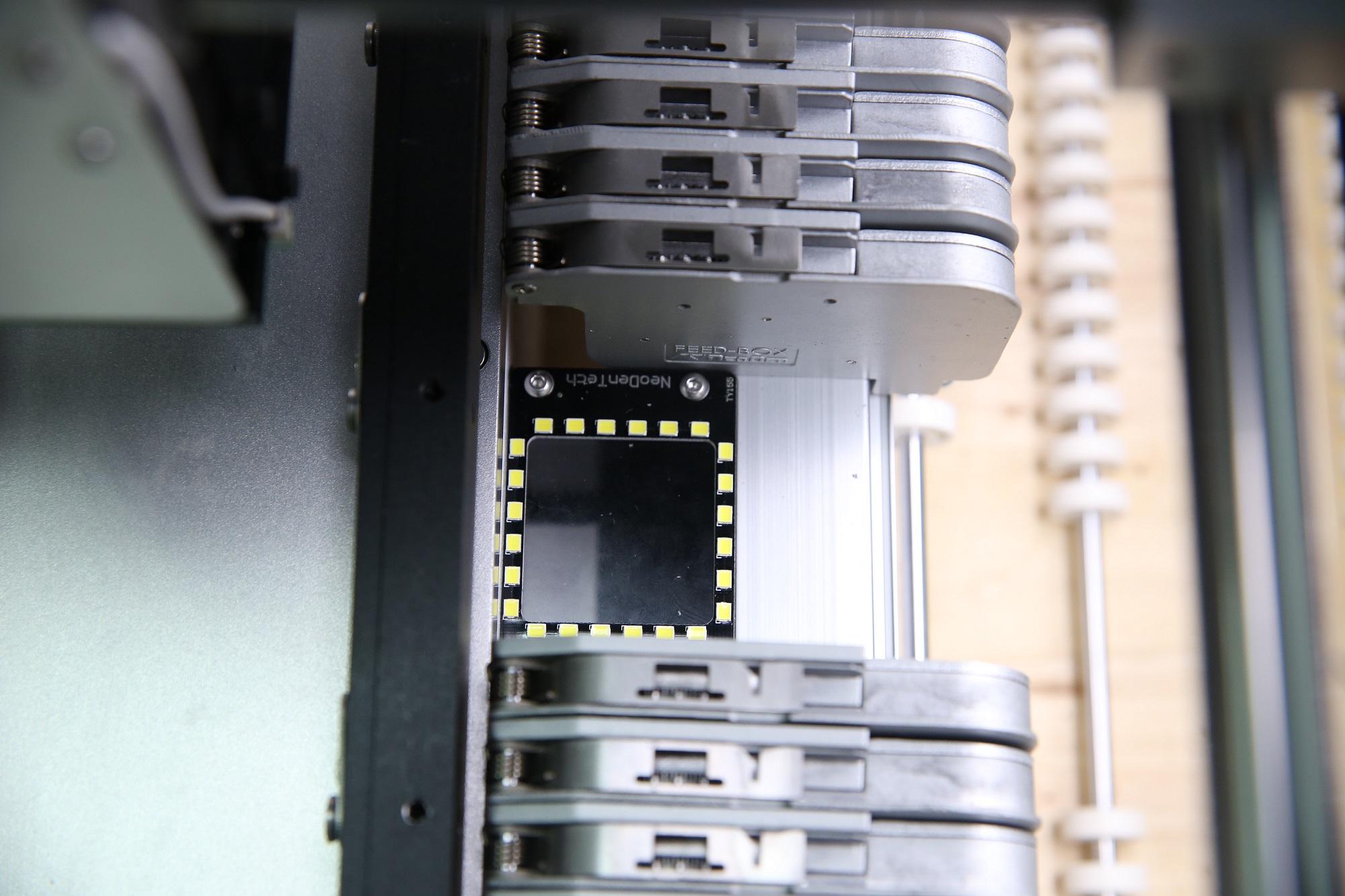

Electric tape-and-reel feeders

The NeoDen4 can accommodate up to 48 8mm tape-and-reel feeders on its left and right rails, and any size feeder (8, 12, 16 and 24mm) can be installed in any combination or order on the left and right sides of the machine.

Packing

Caution

Transport

1. Take necessary security measures, to prevent upside down or fall when lifting ormoving.

Open

1. Please read all instruction in the wooden box.

2. Do not cut the packing tape by knife, to avoid scratch the machine.

3. Keep all packing material.

Installation

1. Please put the machine in a horizontal place.

2. Please keep the floor clean and dry, and the machine should be grounded, to prevent electric shock or leakage.

Provide one-stop SMT assembly production line

Related products

|

|

|

| Automatic conveyor J12 | Reflow Oven IN6 |

If you need, please feel free to contact us.

FAQ

Q1: This is the first time I use this kind of machine, is it easy to operate?

A: Yes. There are English manual and guide video that show you how to use machine.

If there is any doubt in the process of operating the machine, please feel free contact us.

We also provide overseas on-site service.

Q2: Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT Machine, Pick and Place Machine, Reflow Oven, Screen Printer, SMT Production Line and other SMT Products.

Q3: What we can do for you?

A: Total SMT Machines and Solution, professional Technical Support and Service.

About us

Exhibition

Certificates

Factory

If you need, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

Our company insists all along the quality policy of "product good quality is base of enterprise survival; buyer fulfillment will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" and also the consistent purpose of "reputation very first, shopper first" for factory Outlets for Desktop Pick And Place Robot - SMT Pick and Place Machine Line SMT chip mounter – Neoden , The product will supply to all over the world, such as: Sri Lanka, Iraq, Roman, Our aim is to help customers realize their goals. We have been making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, you should do not hesitate to contact us.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.