Desktop PCB Assembly Machine

NeoDen4

Desktop PCB Assembly Machine

The fourth-generation model

Description

Specification

| Product name | Desktop PCB Assembly Machine |

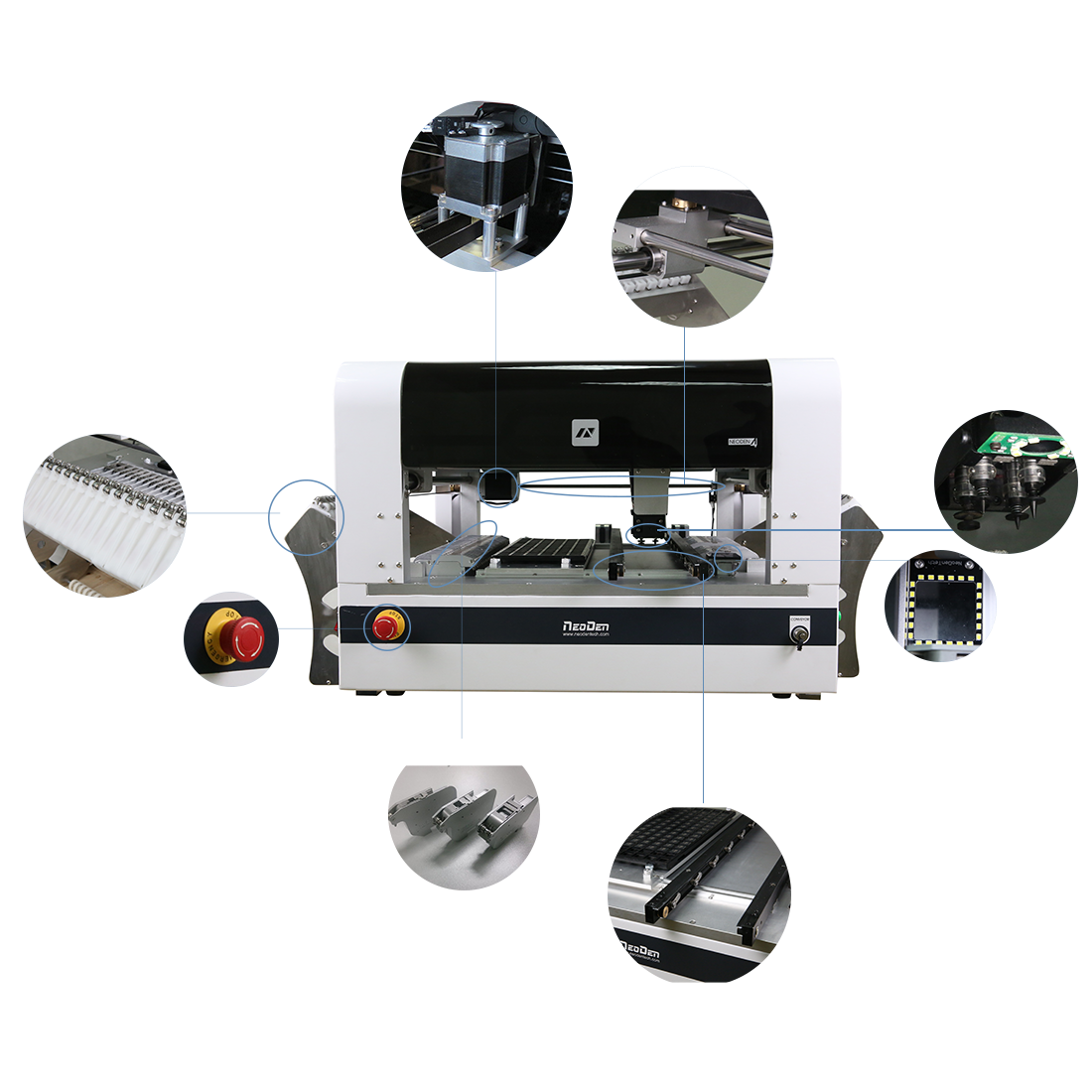

| Machine Style | Single gantry with 4 heads |

| Placement Rate | 4000 CPH |

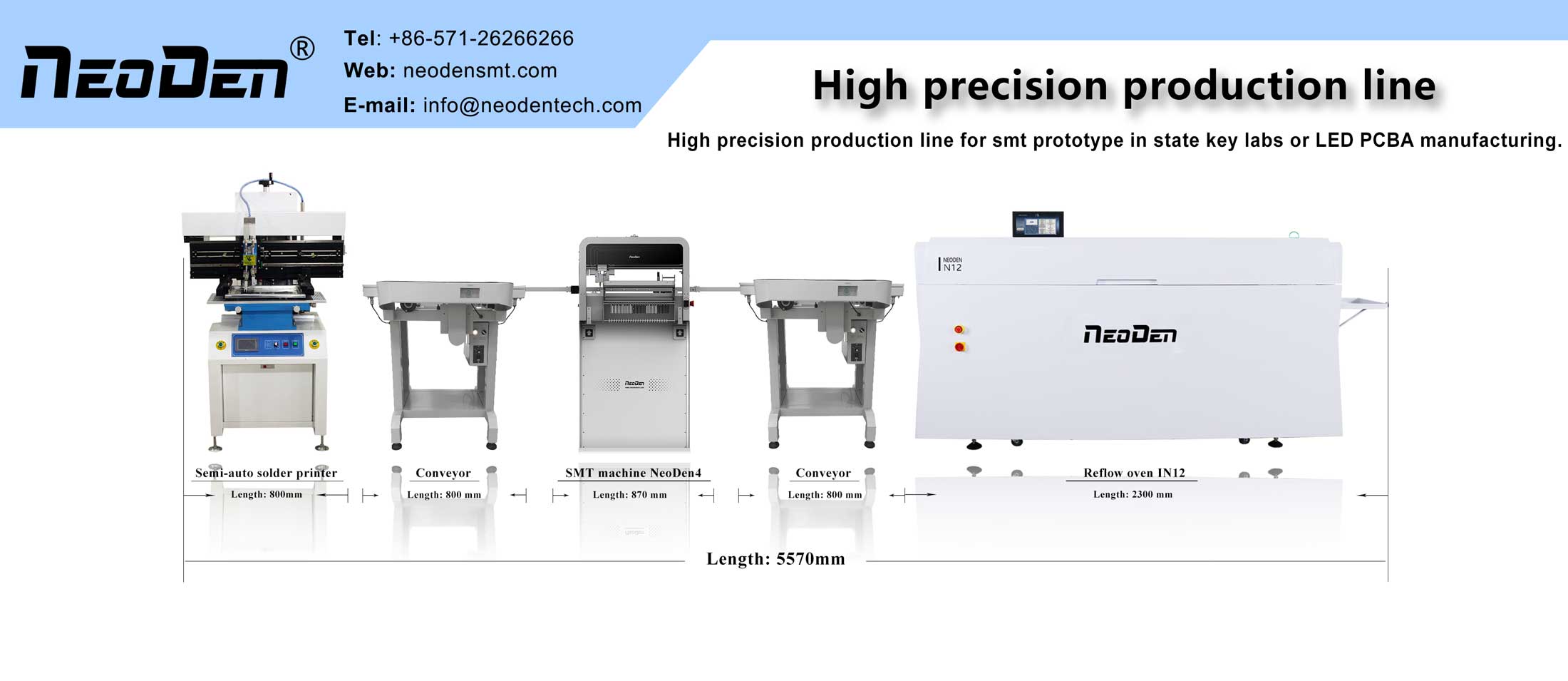

| External Dimension | L 870×W 680×H 480 mm |

| Max applicable PCB | 290mm*1200mm |

| Feeders | 48pcs |

| Average working power | 220V/160W |

| Component Range | Smallest Size: 0201 |

| Biggest Size: TQFP240 | |

| Max Height: 5mm |

Details

Electric tape-and-reel feeders, vibration feeders and virtual tray feeders are all supported.

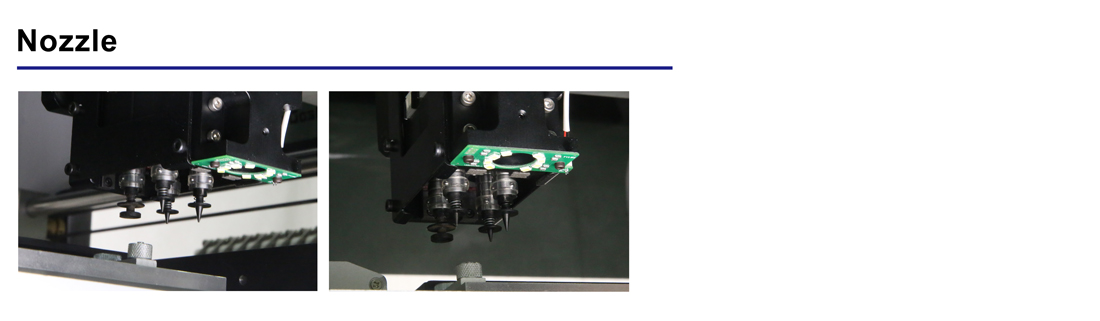

The spring-loaded nozzles simply snap in and pull out of the head.

Any Nozzle can be installed in any of the four locations on the head.

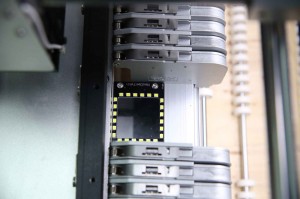

The NeoDen4 features a high-precision, two-camera vision system.

The cameras are made by Micron Technology and are precisely aligned to the nozzles using the single unified configuration/operation application that loads on power-on.

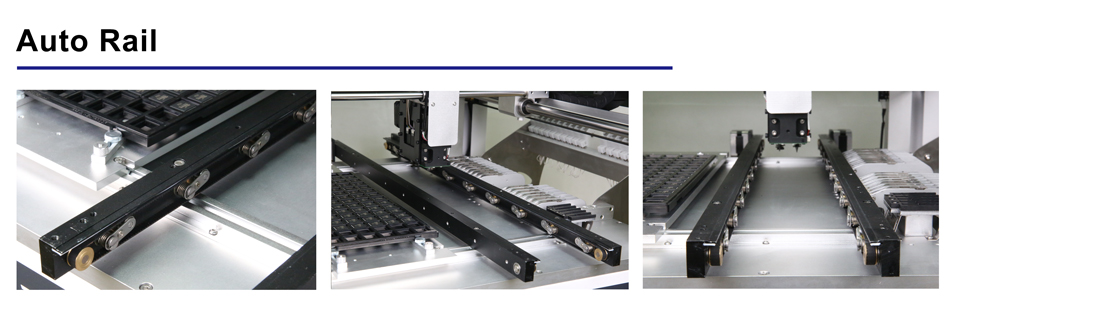

The rail system allows automatic feeding of PCBs, automatic alignment of the board with the camera, and automatic ejection from the front of the machine or the rear.

Rear-ejection is useful when the machine is connected to an optional conveyor that can deliver the finished board directly to the reflow oven or to another NeoDen4.

The NeoDen4 can accommodate up to 48 8mm tape-and-reel feeders on its left and right rails, and any size feeder (8, 12, 16 and 24mm) can be installed in any combination or order on the left and right sides of the machine.

Any area of the table may be used for components awaiting placement, or for the board under manufacture.

Transport

Take necessary security measures, to prevent upside down or fall when lifting or moving.

Open

1. Please read all instruction in the wooden box

2. Do not cut the packing tape by knife, to avoid scratch the machine

3. Keep all packing material.

Working Environment

1. Do not use machine in a noisy environment, such as high frequency welding machine.

2. Do not use machine if the power supply voltage exceeds the rated voltage ± 10%.

3. Do not use machine and pull the plug when thunder to avoid any accident caused by damaged electrical component.

Package

If you need, please feel free to contact us for more information.

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products.

We have our own R & D team and own factory, taking advantage of our own rich experienced R&D, well trained production, won great reputation from the world wide customers.

Owned the own machining center, skilled assembler, tester and QC engineers, to ensure the strong abilities for NeoDen machines manufacturing, quality and delivery.

NeoDen supplies life-long technical support and service for all of the NeoDen machines, moreover, regular software updates based on the using experiences and actual daily request from the endusers.

Certification

Exhibition

FAQ

Q1: Can you do OEM and ODM?

A: Yes, OEM and ODM are both acceptable.

Q2: Which payment form you can accept?

A: T/T, Western Union, PayPal etc.

We accept any convenient and swift payment term.

Q3: What is your advantage compared with your competitors?

A: (1). Qualified Manufacturer

(2). Reliable Quality Control

(3). Competitive Price

(4). High Efficiency working (24*7hours)

(5). One-Stop Service

One Stop SMT Equipments Manufacturer

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.