China wholesale Chip Mounter Machine - Neoden S1 – Neoden

China wholesale Chip Mounter Machine - Neoden S1 – Neoden Detail:

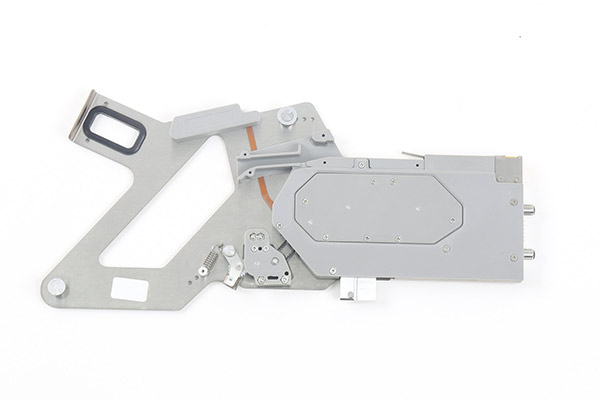

1. Laser camera, flying alignment with high accuracy and high efficiency

2. Fully modular design, with better power protection features and stability, easy after-sales maintenance

3. Comes with 4 pick-up heads, 6 SMD nozzles

4. Linux system, ARM hardware core board improve significantly in low power consumption and scalability

5. Automatic adjustment conveyor system

6. UI interface, touch screen operation, no need key board & mouse, ease of use

7. Linear encoders, monitor the entire coordinate system, which can improve the running speed and ensure the placement accuracy

8. Support 0201, LED, BGA, 0.4mm pitch QFP, SMT Connectors and others

9. Support cut tape, loose, tube, or tray components

10. TUV NORD CE approved

Specification

| Model | NeoDen S1 |

| Number of Heads with Vision enabled | 4 |

| Placement Rate | 6000CPH |

| Feeder Capacity | Tape Reel Feeders:58(All 8mm width) |

| Tape width | 8mm,12mm,16mm,24mm |

| Vibration Feeders | 5 |

| IC Tray Capacity | 94 |

| Smallest Component size | 0201 |

| Largest Component size | 35x35mm(Lead pitch 0.4mm) |

| Applicable Components | 0201,BGA,SOIC,SSOP,QFN,TQFP,Led Component,Diode,Triode,Tack Switch |

| Component Height Maximum | 8mm |

| Rotation | +/-180(360) |

| Positioning Accuracy | +/-0.02mm |

| Max Placement Area | 290*1500mm(without waffle Tray) 160*1500mm(With 1 waffle Tray) |

| Programming | SOFTWARE AUTOMATIC PROGRAMMING MANUAL MECHANICAL PROGRAMMING |

| Power Supply | 220V/110V |

| Power | 150W |

| External Dimensions:Machine | 98*76*58CM(not include Alarm Lamp height) |

| Net Weight | 98KGS |

| Gross weight | 209kg |

| Packing Size | 101*88*135CM |

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of China wholesale Chip Mounter Machine - Neoden S1 – Neoden , The product will supply to all over the world, such as: Borussia Dortmund, Jersey, Jamaica, we have complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, professional sales service team. With all those advantages, we are going to create"the reputable international brand of nylon monofilaments", and spreading our products to every corner of the world. We are keep moving and try our best to serve our customers.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.