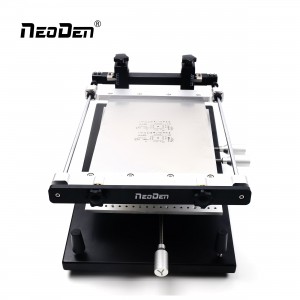

Automatic soldering printer|stencil printer

Automatic soldering printer|stencil printer

Description

Specification

Automatic soldering printer Real time detection of solder paste margin (thickness) on stencil, intelligent prompt tin adding.

| Product name | Automatic soldering printer |

| Maximum board size(X x Y) | 450mm x 350mm |

| Minimum board size(X x Y) | 50mm x 50mm |

| PCB thickness | 0.4mm~6mm |

| Warpage | ≤1% Diagonal |

| Maximum board weight | 3Kg |

| Board margin gap | Configuration to 3mm |

| Maximum bottom gap | 20mm |

| Transfer speed | 1500mm/s(Max) |

| Transfer height from the ground | 900±40mm |

| Transfer orbit direction | L-R,R-L,L-L,R-R |

| Machine weight | Appro.1000Kg |

Features

Accurate optical positioning system

Four way light source is adjustable, light intensity is adjustable, light is uniform, and image acquisition is more perfect;Good identification (including uneven mark points), suitable for tinning, copper plating,Gold plating, tin spraying, FPC and other types of PCB with different colors.

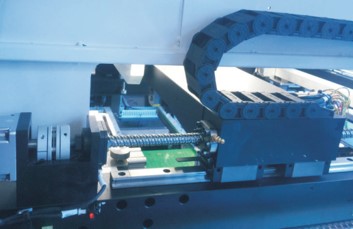

High efficiency and high adaptability stencil cleaning system

The new wiping system ensures full contact with the stencil ; three cleaning methods of dry, wet and vacuum, and free combination can be selected; soft wear-resistant rubber wiping plate, thorough cleaning, convenient disassembly, and universal length of wiping paper.

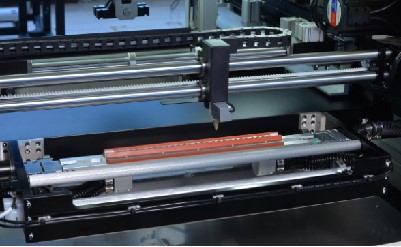

Printing axis servo drive

The scraper Y axis adopts servo motor drive through screw drive,to improve accuracy grade,operational stability and extend the service life,to provide customers with a good printing control platform.

Squeegee pressure close-loop feedback control

It can accurately display the original pressure value of squeegee,intelligently adjust the depth of the blade pressing down ensure the pressure value is constant during the printing process and obtain the highest process control,achieve perfect printing of high density and fine spacing devices.

Provide one-stop SMT assembly production line

Related products

FAQ

Q1: Is it hard to use these machines?

A: No,not hard at all.For our previous clients,at most 2 days is enough to learn to operate the machines.

Q2: Can we customize the machine?

A: Of course. All of our machines can be customized.

Q3: How about the warranty?

A: We support one year warranty. We will help you in time. All the spare parts will be provided free of charge for you within the warranty period.

About Us

Exhibition

Certification

Our Factory

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.