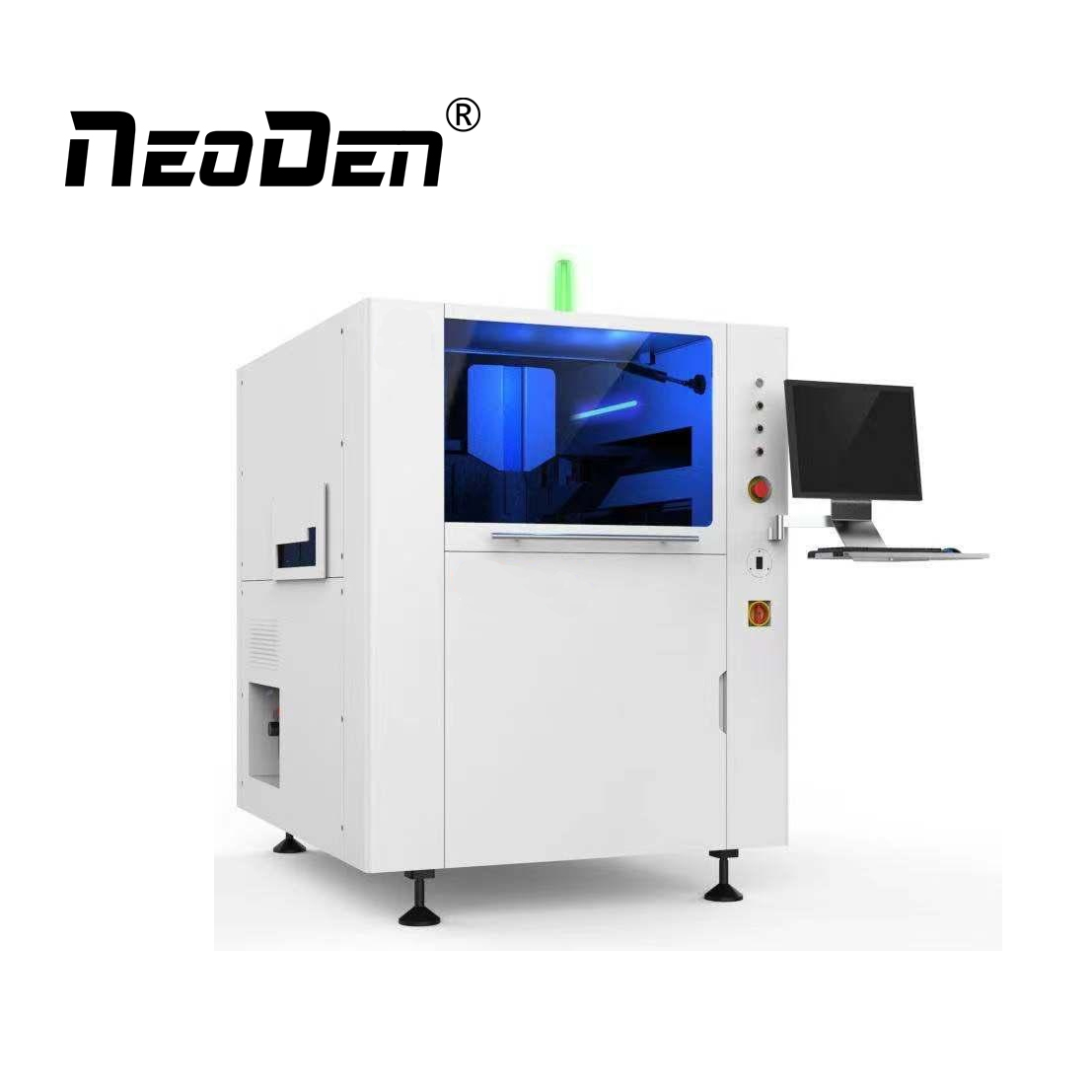

Automatic Solder Paste Stencil Printer

Automatic Solder Paste Stencil Printer

Specification

| Product name | Automatic Solder Paste Stencil Printer |

| Maximum board size(X x Y) | 450mm x 350mm |

| Minimum board size(X x Y) | 50mm x 50mm |

| PCB thickness | 0.6mm~14mm |

| Warpage | ≤1% Diagonal |

| Maximum board weight | 10Kg |

| Board margin gap | Configuration to 3mm |

| Maximum bottom gap | 20mm |

| Transfer speed | 1500mm/s(Max) |

| Transfer height from the ground | 900±40mm |

| Transfer orbit direction | L-R, R-L, L-L, R-R |

| Machine weight | Appro.1000Kg |

Maintain

I. Printing part

1. Check whether there are residues of solder paste on the printing table.

2. Use a clean cotton cloth with a little alcohol to do the necessary cleaning.

3. Check the transmission system and positioning clamping parts on whether there are residues of solder paste.

4. Take off the cover around the table and clean the guide rod and linear guide with clean cotton cloth.

5. Lubricate the guiding screw and linear guide with special lubricant for NSK guideway and screw.

6. Clean the sensor with a cotton cloth with a little alcohol.

7. Adjust the synchronous belt in X and Y movement direction when needed.

8. Replace the cover plate.

Option

1. Overall bottom suction chamber vacuum

2. Bottom multipoint partial vacuum

3. Edge lock clamping plate

Board support method Magnetic thimble, special work holding device (option: Grid-Lok)

Our Service

Provide product instructions

YouTube video tutorials

Experienced after-sales technicians, 24 hours online service

with our own manufactory and more than 10 years of experience in SMT industry

We can provide customers with the most cost-effective products.

Provide one-stop SMT assembly production line

Related products

About us

Factory

Quick facts about NeoDen

① Established in 2010, 200+ employees, 8000+ Sq.m. factory

② NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040

③ Successful 10000+ customers across the globe

④ 30+ Global Agents covered in Asia, Europe, America, Oceania and Africa

⑤ R&D Center: 3 R&D departments with 25+ professional R&D engineers

⑥ Listed with CE and got 50+ patents

⑦ 30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours

Certification

Exhibition

FAQ

Q1: How can I buy machine from you?

A: (1) Consult us on line or by e-mail.

(2) Negotiate and confirm the final price, shipping, payment method and other terms.

(3) Send you the perfroma invoice and confirm your order.

(4) Make the payment according to the method put on proforma nvoice.

(5) We prepare your order in terms of the proforma invoice after confirming your full payment. And 100% quality check before shipping

(6) Send your order via express or by air or by sea.

Q2: What's the way of shipping?

A: These are all heavy machines; we suggest you use cargo ship.

But components for mending the machines, air transportation would be fine.

Q3: How do I pay?

A: My friend, there are many ways.

T/T(we prefer this one), Western Union, PayPal, choose your favorite one.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.