AOI Inspection Machine

NeoDen ND800 AOI Inspection Machine

Product Overview

Brand

Country/Region of Manufacture

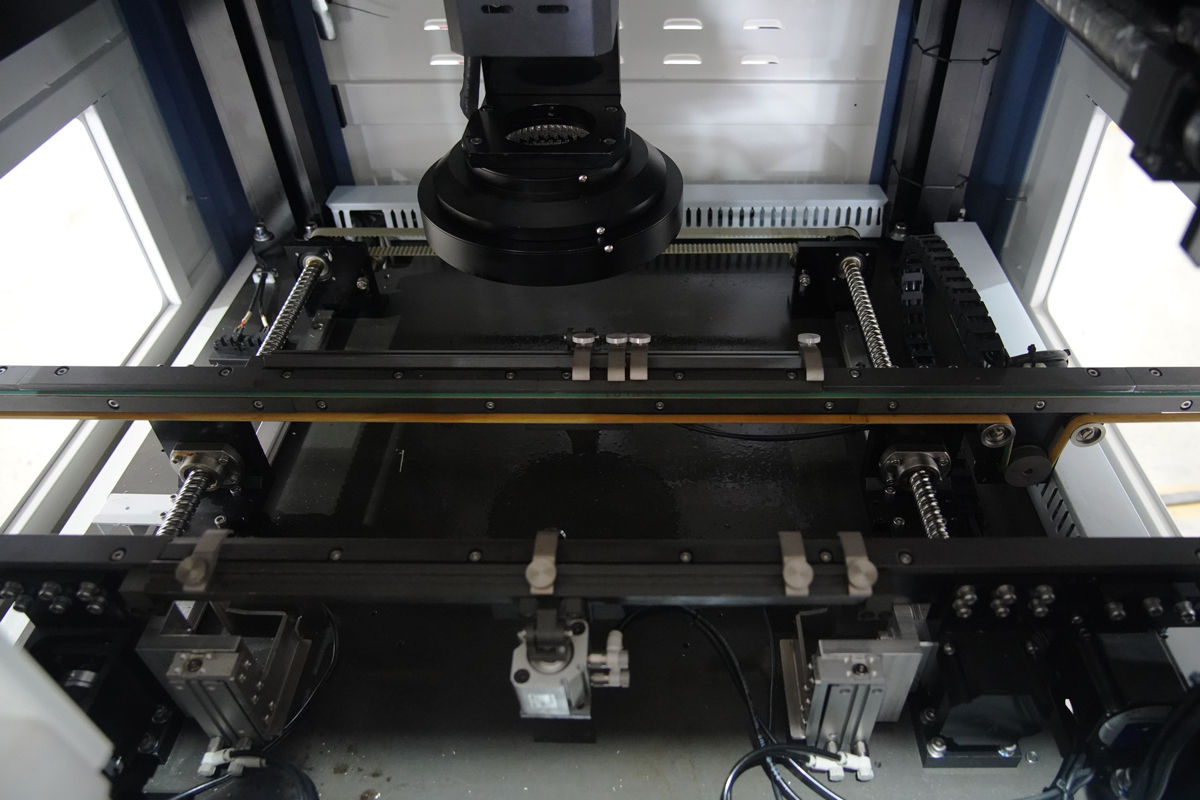

Max. PCB Size

Min. PCB Size

Machine dimension

Speed

NeoDen

China

400*360mm

50*50mm

980*980*1620mm

830mm/Sec (Max)

Model

Application

Max. Bottom Gap

Min. Top Gap

PCB Thickness

Weight

ND800

PCB Testing, SMT production

75mm

35mm

0.3-5mm

550Kg

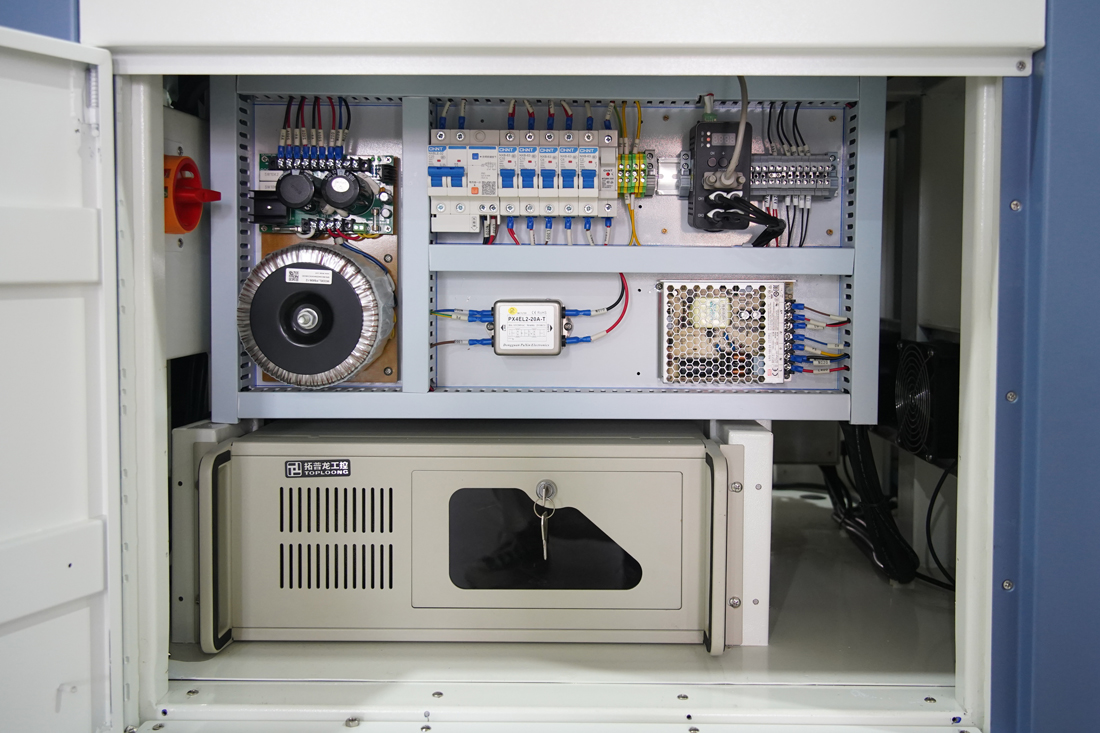

Description

AOI Inspection Machine application

After stencil printing, pre/post reflow oven, pre/post wave soldering, FPC etc.

Inspection Items

1. Stencil printing: Solder unavailability, insufficient or excessive solder, solder misalignment, bridging, stain, scratch etc.

2. Component defect: Missing or excessive component, misalignment, uneven, edging, opposite mounting, wrong or bad component etc.

3. DIP: Missing parts, damage parts, offset, skew, inversion, etc.

4. Soldering defect: Excessive or missing solder, empty soldering, bridging, solder ball, IC NG, copper stain etc.

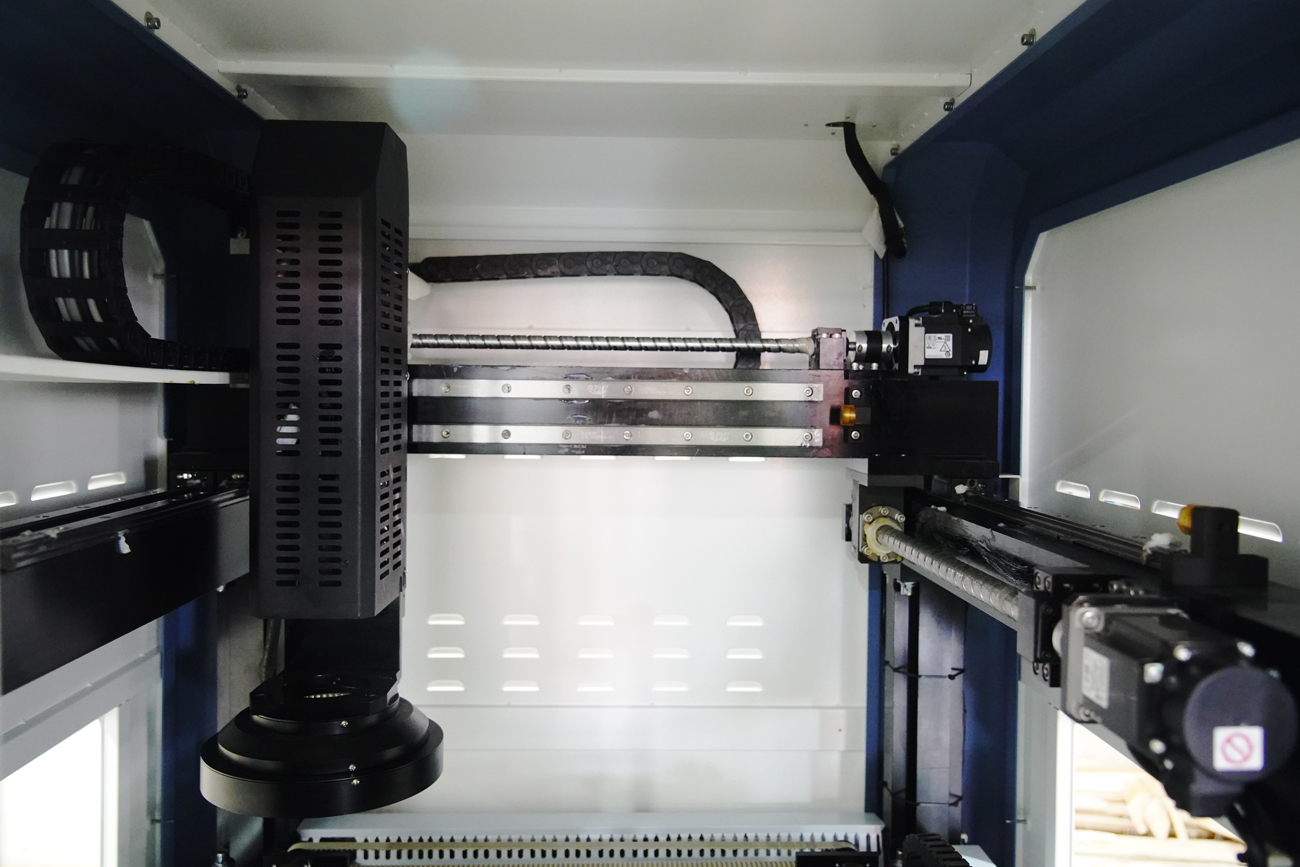

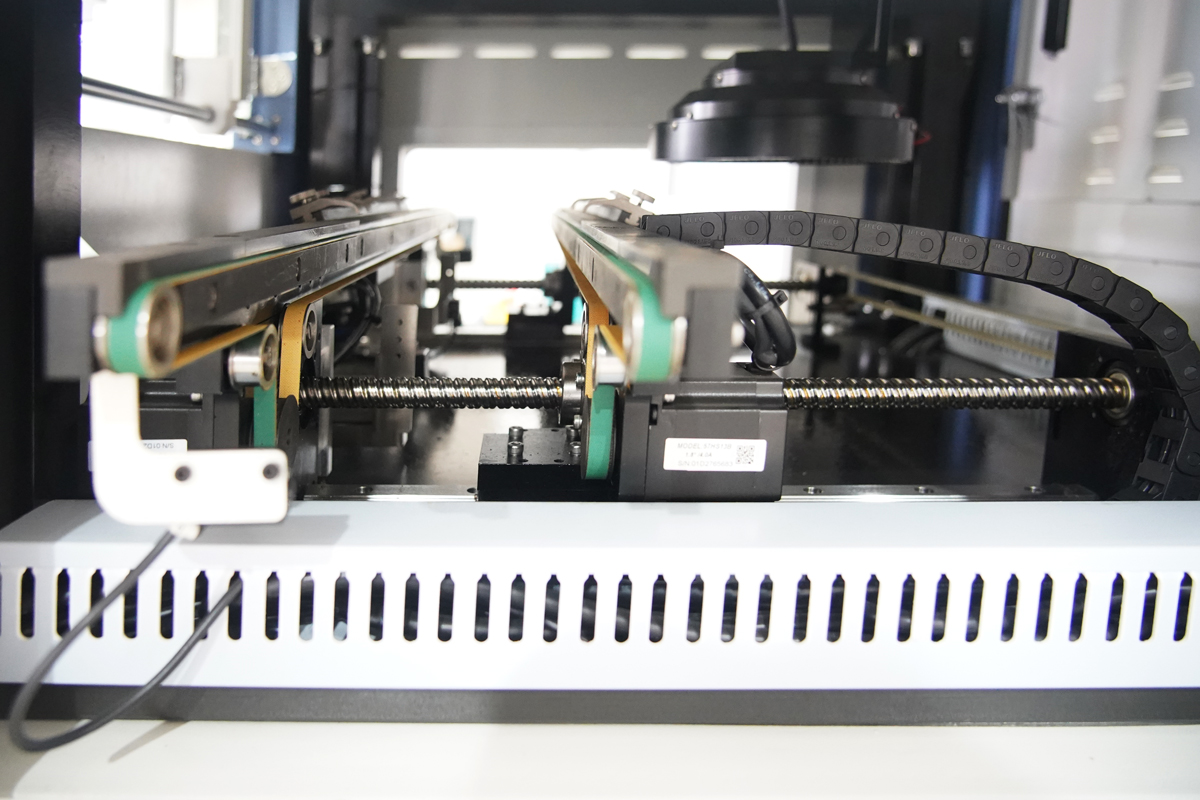

Optical system

Camera: 5 million pix full color high speed industrial digital camera, 20 million pix camera optional.

Lens resolution: 10um/15um/18um/20um/25um, can be custom-made.

Lighting source Annular stereo multi-channel color light, RGB/RGBW/RGBR/RWBR optional.

Minimum component: 0201 chip, 0.3 pitch IC.

Details

Our Service

1. More Professional service in PNP machine field

2. Better manufacture ability

3. Various payment term to choose: T/T, Western Union, L/C, Paypal

4. High quality/Safe material/Competitive price

5. Small order available

6. Quickly response

7. More safe and fast transport

About us

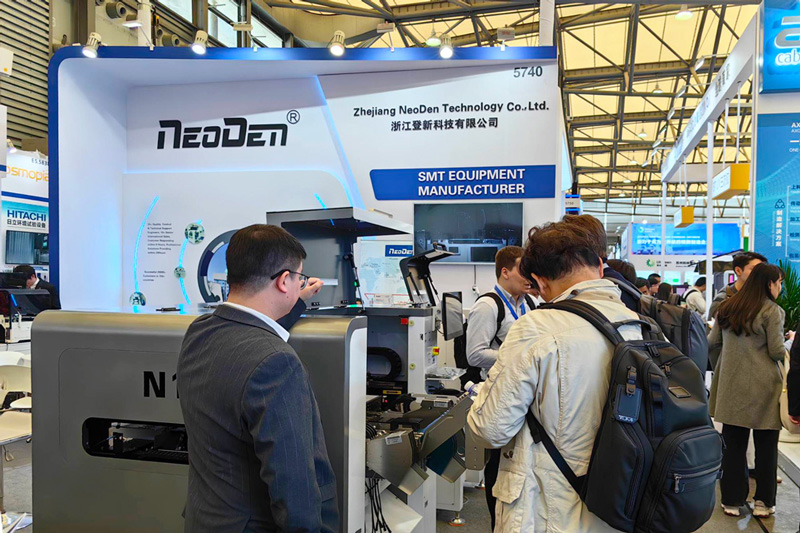

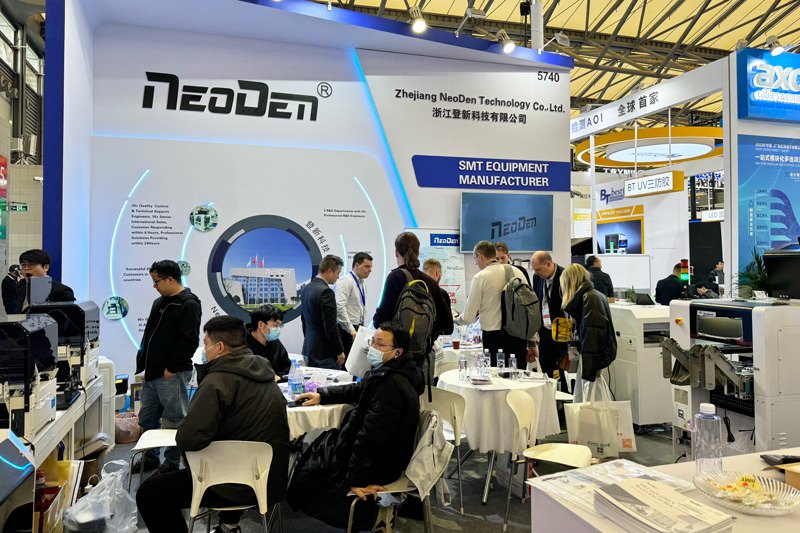

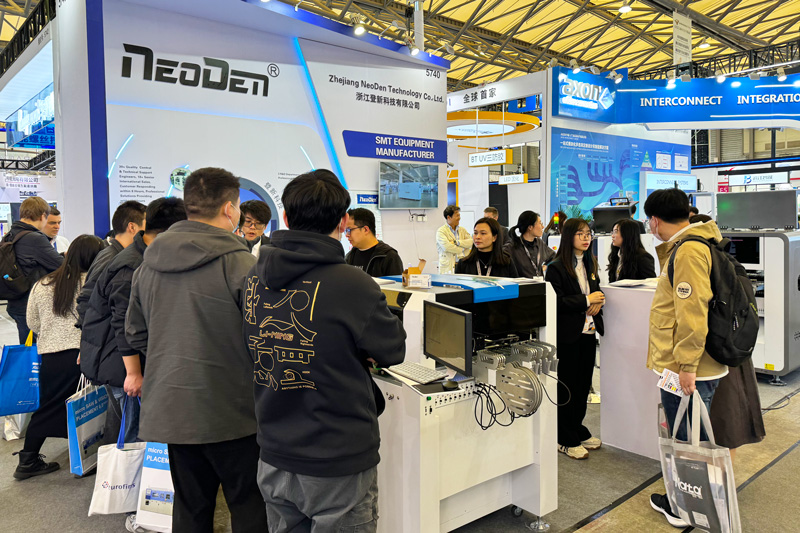

Exhibition

Certification

Factory

Zhejiang NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products.

We are in a good position not only to supply you high quality pnp machine, but also the excellent after sales service.

Well-trained engineers will offer you any technical support.

10 engineers powerful after-sales service team can respond customers queries and enquiries within 8 hours.

Professional solutions can be offered within 24 hours both workday and holidays.

FAQ

Q1. What about the lead time for mass SMT production line?

A. Honestly, it depends on the order quantity you place the order.

Always 10-20 days based on general order.

Q2. What is your advantage compared with your competitors?

A. 1. Qualified Manufacturer

2. Reliable Quality Control

3. Competitive Price

4. High Efficiency working (24*7hours)

5. Provide One-Stop SMT service

Q3. What's the way of shipping?

A. These are all heavy machines.

We suggest you use cargo ship.

But components for mending the machines, air transportation would be fine.

If you need, please feel free to contact us!

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.